Chinlon chemical fiber titanium dioxide inorganic film-coating treatment process

A technology of titanium dioxide and inorganic coating, applied in the direction of fiber treatment, fiber type, light-resistant fiber, etc., can solve the problem of accelerated photoaging of nylon fiber, and achieve the effect of excellent optical performance, improved weather resistance, and improved optical activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

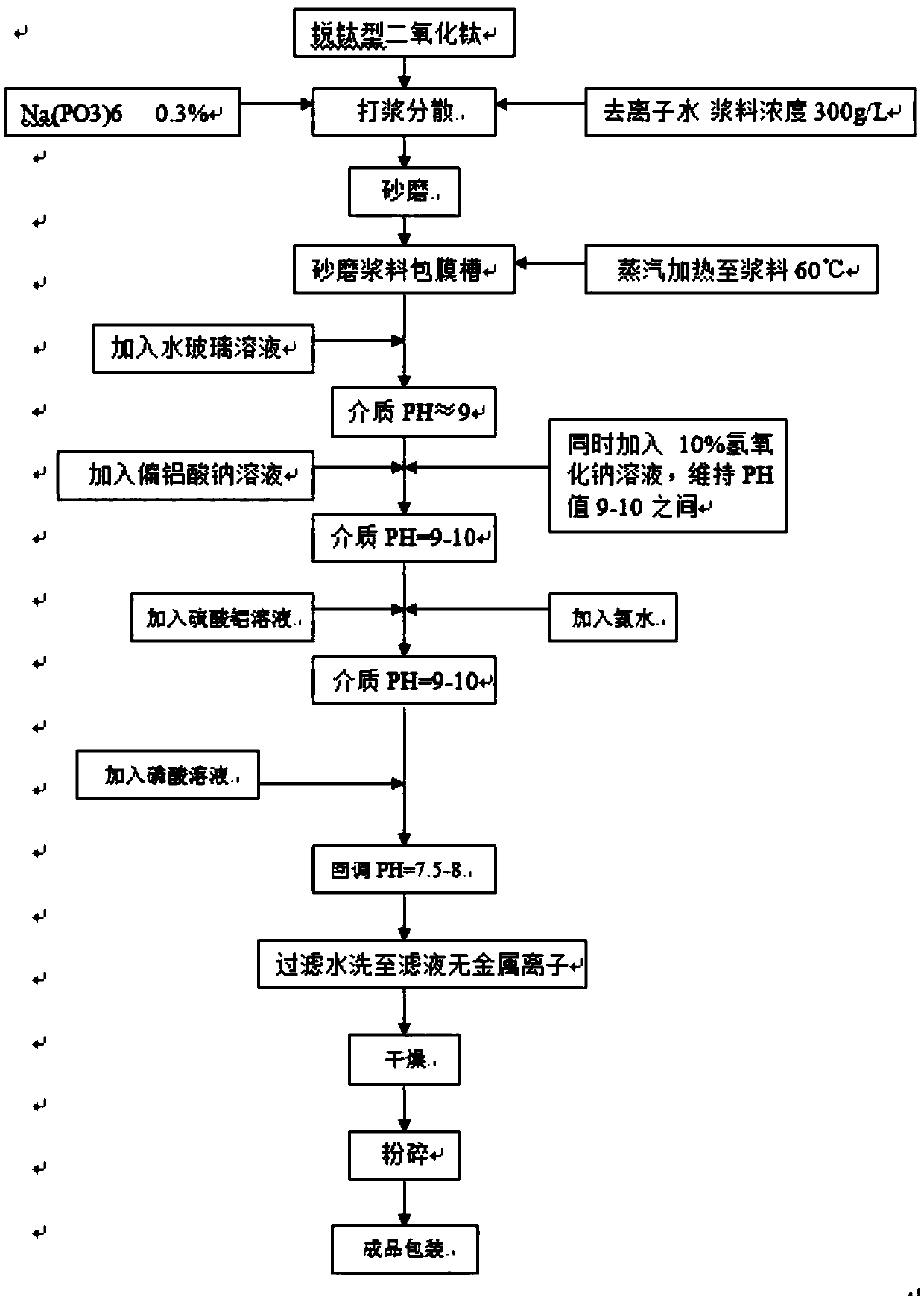

[0031] like figure 1 As shown, the present invention provides a technical solution: a nylon chemical fiber titanium dioxide inorganic coating treatment process, including:

[0032] Step 1: Prepare anatase titanium dioxide

[0033] Through experiments, sodium hexametaphosphate is preferably used as a dispersant for dispersing and beating, and the addition amount is 0.25-0.3% of the total amount of coated titanium dioxide;

[0034] Obtain plasma water through RO reverse osmosis + mixed bed, add plasma water to the dispersant for sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com