Oiling device for textile elasticizer

A texturing machine and oil tank technology, applied in textiles and papermaking, etc., can solve the problems of polluting the oil tank environment, affecting the quality of the silk thread, and low cleanliness of the oiling roller, and achieving the effect of good effect and convenient oil recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

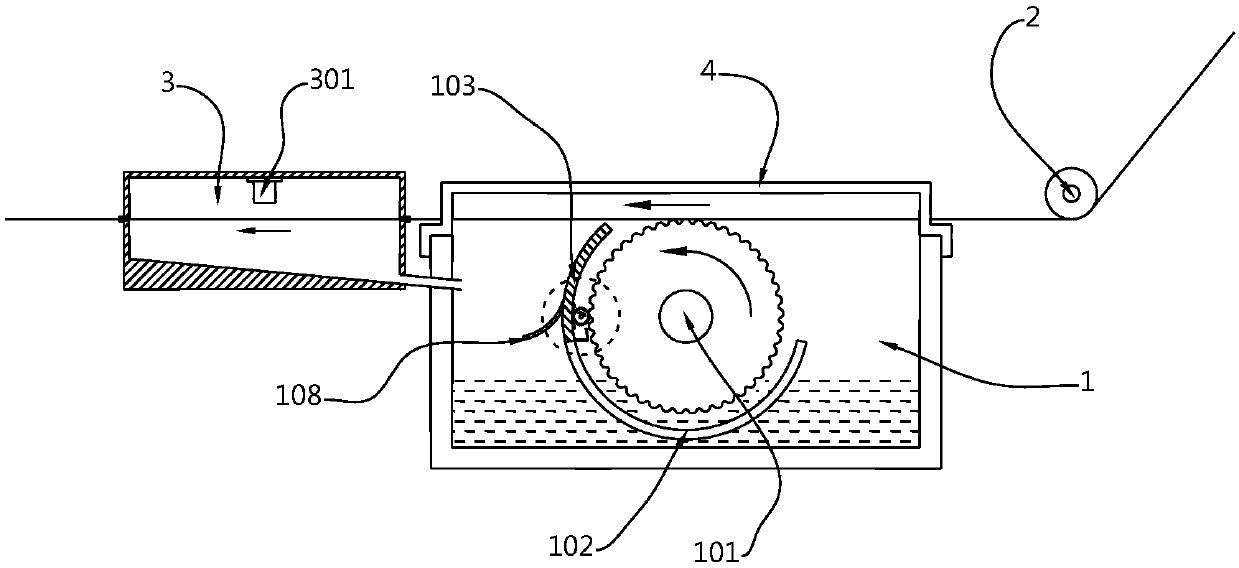

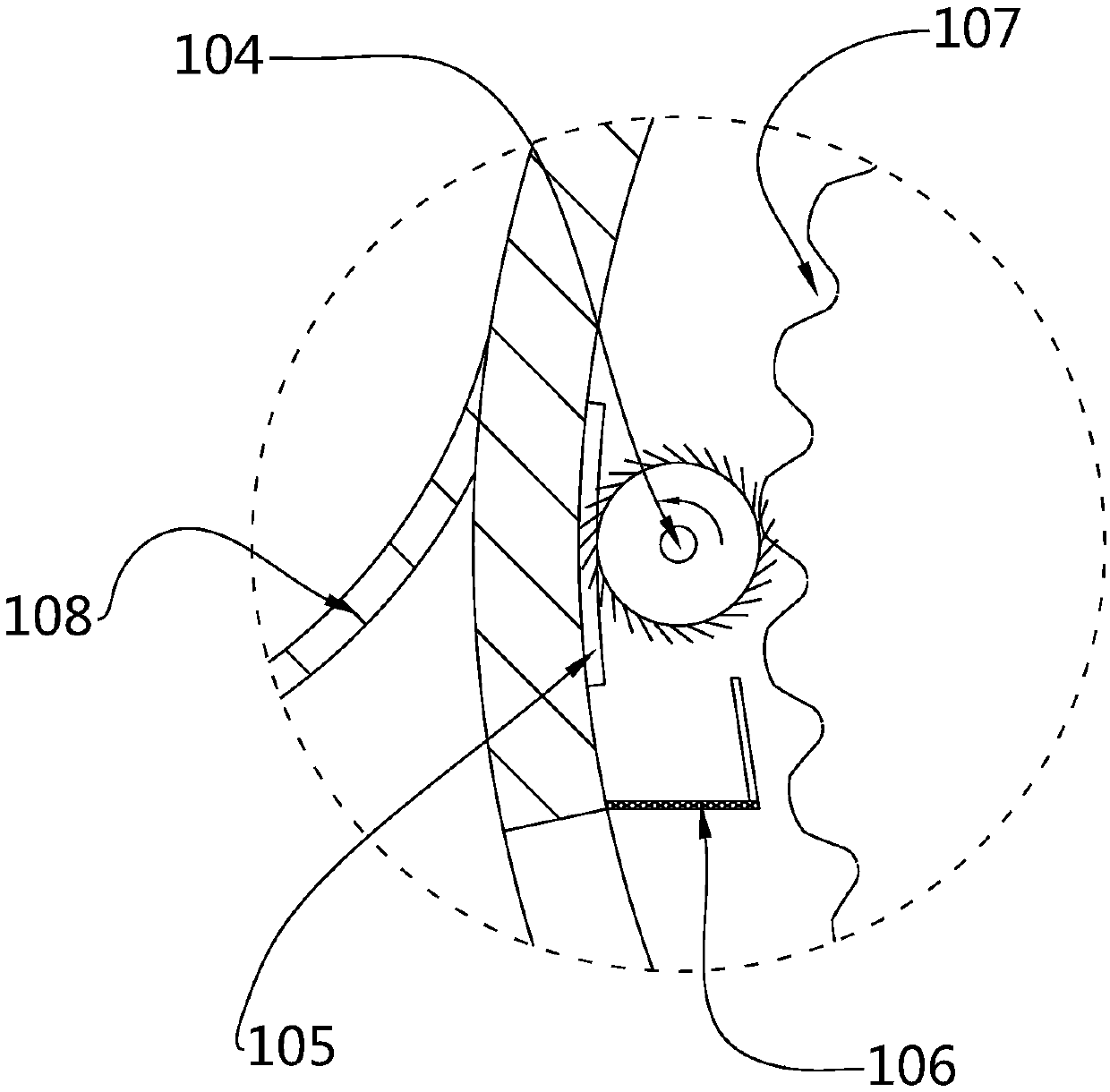

[0016] Embodiment: a kind of oiling device for texturing texturing machine, structure such as figure 1 and figure 2 As shown, it includes an oil tank 1, one side of the oil tank 1 is provided with a guide roller 2, and the other side of the oil tank 1 is connected with an oil recovery tank 3 through a pipeline; There is an arc filter screen 102, and an end of the arc filter screen 102 near the oil recovery tank 3 is provided with an extended arc baffle plate 103, and a brush roller 104 is arranged between the arc baffle plate 103 and the oiling roller 101, and The relative arc baffle plate 103 of the brush roller 104 is provided with a hair cleaning plate 105, and the hair brush roller 104 below is provided with a hair collection groove 106 connected with the arc baffle plate 103, and the hair collection groove 106 bottom is provided with a filter hole; The oil recovery tank 3 is provided with a pneumatic vibrator 301, and the bottom of the oil recovery tank 3 is an inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com