Melt-blow nozzle and fiber preparation device

A nozzle and meltblown technology, applied in melt spinning, textile and papermaking, spinneret assemblies, etc. Problems such as increased processing difficulty, to achieve the effect of reducing processing difficulty, reducing diameter, and improving stretching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

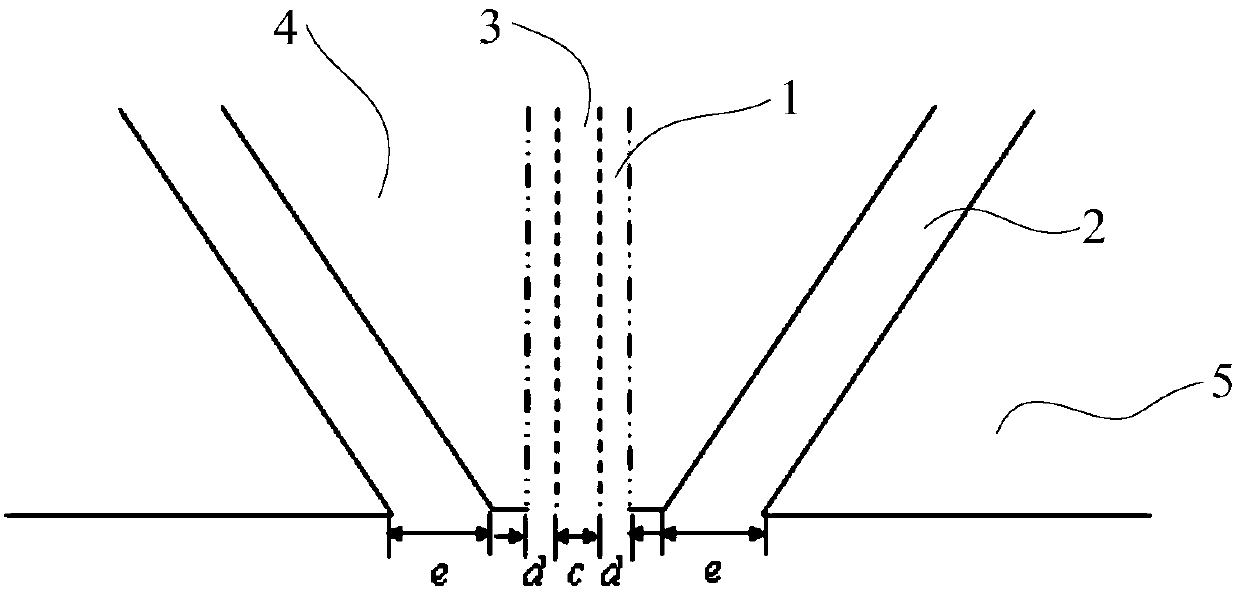

[0050] The polymer melt is extruded from the annular spinneret holes to form filaments, the high-speed first airflow is ejected from the first airflow passage, and at the same time, the high-speed second airflow is ejected from the second airflow passage. Wherein, the included angle of two second airflow channels is 60 °, the outlet width e of the second airflow channel is 0.6mm, the diameter c of the first airflow channel is 0.1mm, and the difference d of the inner and outer radii of the annular spinneret holes is 0.35mm. Provide raw material polypropylene, the melt flow rate of polypropylene is 1000g / 10min, the flow rate of polypropylene is 0.022g / s, the initial temperature of polypropylene is 290°C, the pressure of the first airflow is 350kPa, and the pressure of the second airflow is 150kPa , The gas pressure of the existing melt-blown double-slot nozzle is 500kPa, and the initial gas temperature is 310°C.

[0051] The average diameter of the melt-blown fibers prepared un...

Embodiment 2

[0053] The polymer melt is extruded from the annular spinneret holes to form filaments, the high-speed first airflow is ejected from the first airflow passage, and at the same time, the high-speed second airflow is ejected from the second airflow passage. Wherein, the included angle of two second airflow channels is 60 °, the outlet width e of the second airflow channel is 0.6mm, the diameter c of the first airflow channel is 0.8mm, and the difference d of the inner and outer radii of the annular spinneret holes is 0.53mm. Provide raw material polypropylene, the melt flow rate of polypropylene is 75g / 10min, the flow rate of polypropylene is 0.006g / s, the initial temperature of polypropylene is 310°C, the pressure of the first airflow is 260kPa, and the pressure of the second airflow is 190kPa , The gas pressure of the existing melt-blown double-slot nozzle is 450kPa, and the initial gas temperature is 380°C.

[0054] The average diameter of the melt-blown fibers prepared unde...

Embodiment 3

[0056] The polymer melt is extruded from the annular spinneret holes to form filaments, the high-speed first airflow is ejected from the first airflow passage, and at the same time, the high-speed second airflow is ejected from the second airflow passage. Wherein, the included angle of two second airflow passages is 60 °, the outlet width e of the second airflow passage is 0.6mm, the diameter c of the first airflow passage is 0.2mm, and the difference d of the inner and outer radii of the annular spinneret holes is 0.36mm. Provide raw material polypropylene, the melt flow rate of polypropylene is 800g / 10min, the flow rate of polypropylene is 0.031g / s, the initial temperature of polypropylene is 280°C, the pressure of the first airflow is 350kPa, and the pressure of the second airflow is 200kPa , The gas pressure of the existing melt-blown double-slot nozzle is 550kPa, and the initial gas temperature is 300°C.

[0057] The average diameter of the melt-blown fibers prepared und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com