Transverse stretching method for prestressed fiber cloth reinforced concrete column

A concrete beam and transverse tensioning technology, which is applied in building maintenance, construction, building construction, etc., can solve problems such as high technical requirements, large tension force, complex construction equipment and construction technology, and achieve small damage and uniform stress , Reduce the effect of tensioning equipment and process requirements

Inactive Publication Date: 2010-12-01

周劲宇 +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This longitudinal tensioning technology requires a large tension force; the construction equipment and construction technology are relatively complicated, and the technical requirements are high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

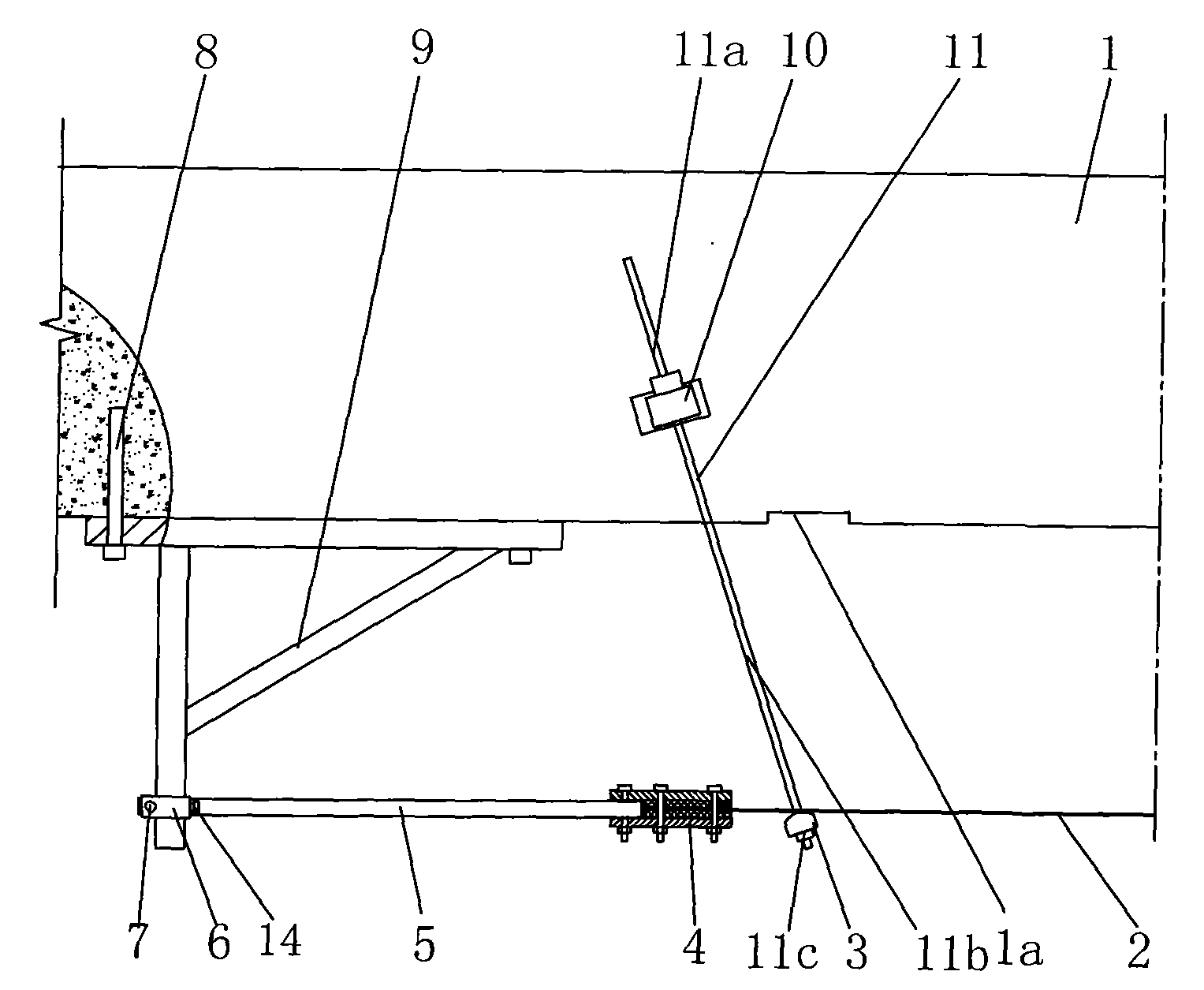

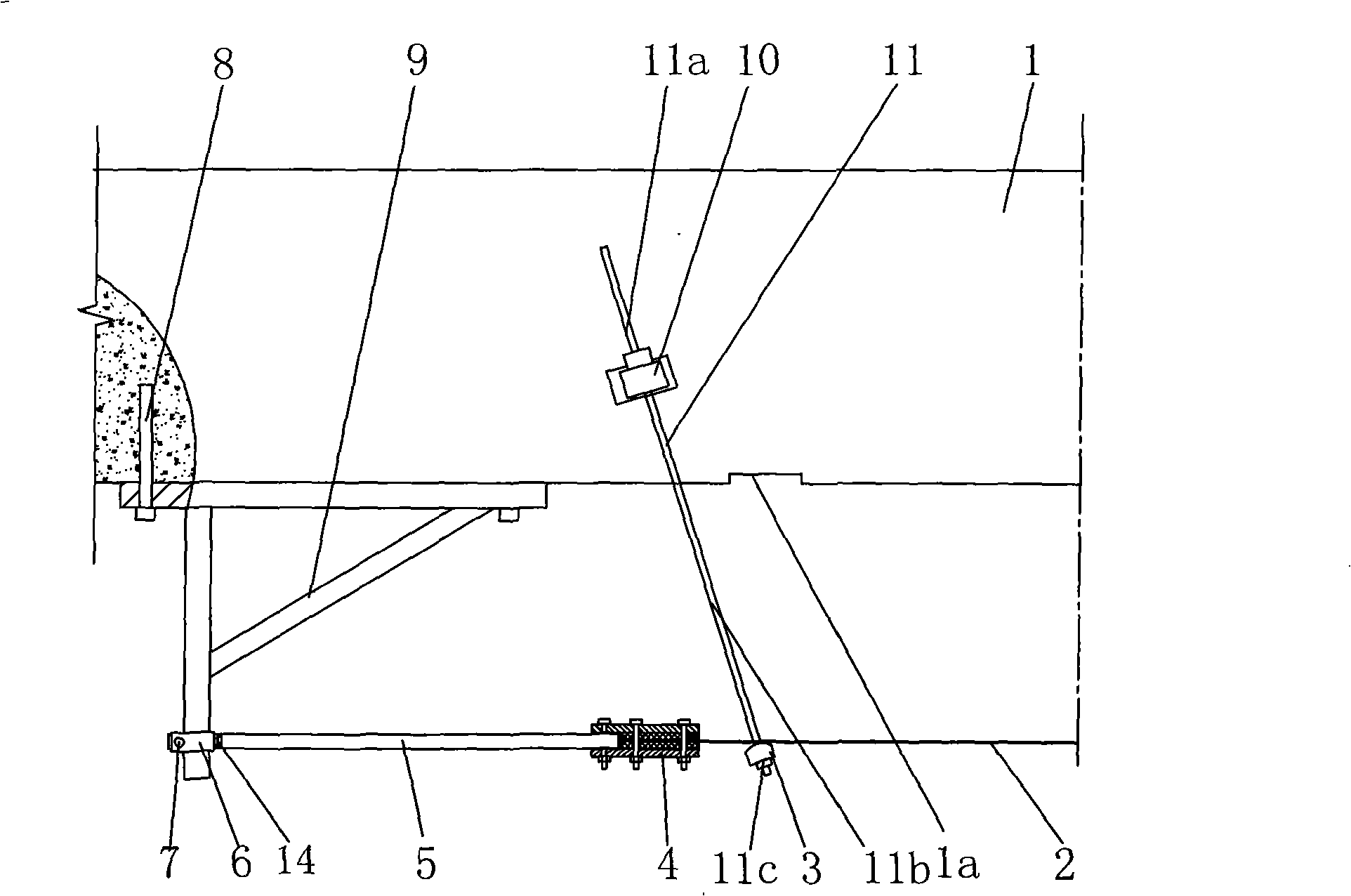

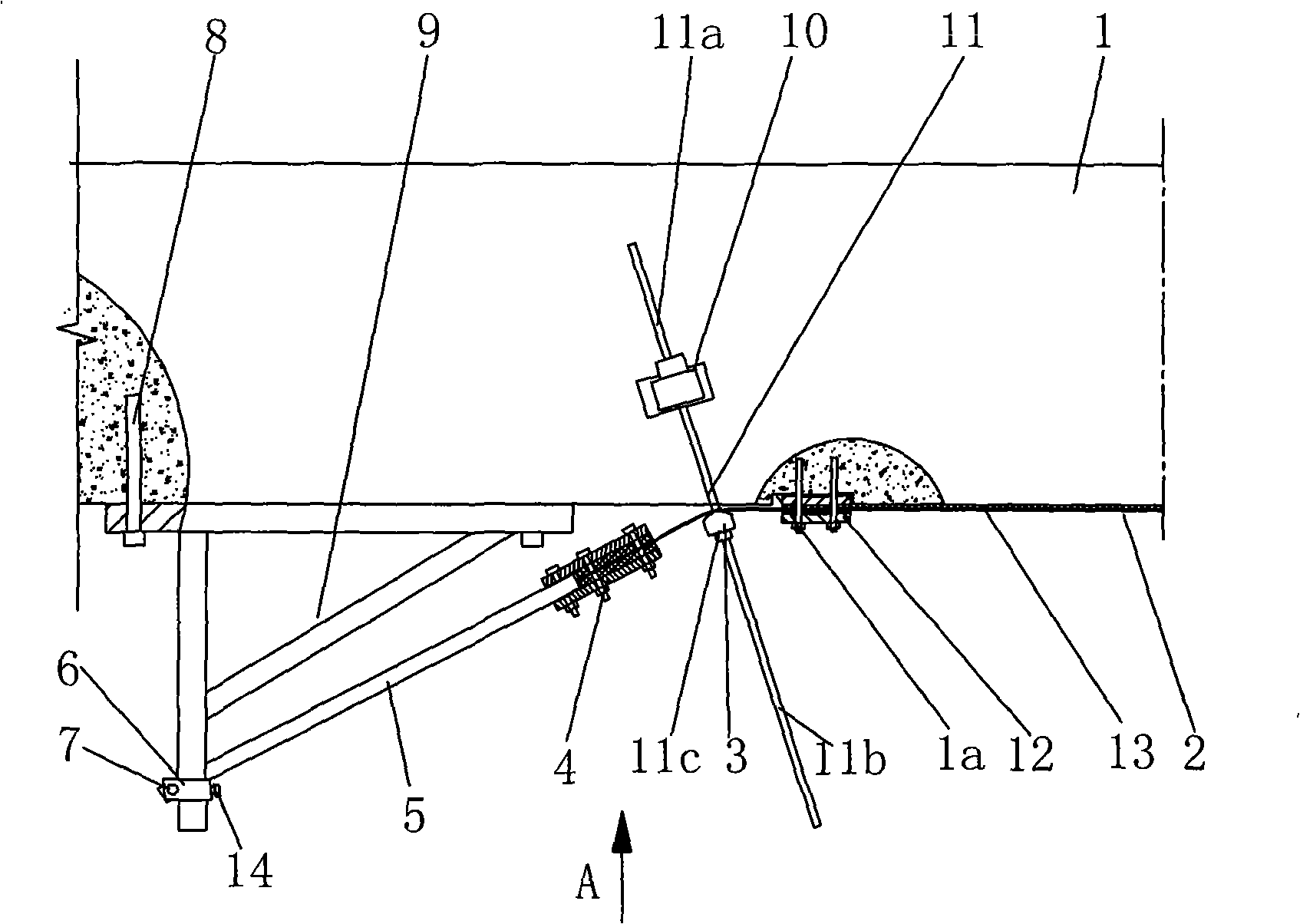

The invention discloses a horizontal tensioning method for concrete beams strengthened with prestressed fiber cloth, wherein, a spacing is set between one end or both ends of the fiber cloth on the surface of the concrete beam and the surface of the concrete beam, and the one end or both ends are fixed; a horizontal bearing beam is arranged on the outer surface of the ends of the fiber cloth horizontally spanning the set spacing to the concrete beam surface; the fiber cloth is pasted to the concrete beam surface bearing the tension stress and directly fixed by moving the horizontal bearing beam towards the concrete beam surface and coating a cementing agent; the method replaces the traditional vertical tensioning fiber cloth with the horizontal tensioning one, and the horizontal tension requires only 1 / 5 to 1 / 7 of vertical tension to achieve the same tensioning effect, so as to significantly lower the requirements for tension equipment and technique; the method adopts simple equipment, has low manufacture cost and is easy to transport and carry, the fiber cloth bears the stress evenly in the tensioning process so as to achieve the good effect of tensioning, and the tension operation only results in small damage to the original concrete structure; and the method can significantly save the construction cost, reduce construction risks and shorten the construction period, so as toachieve the significant comprehensive technical and economic efficiency.

Description

Transverse Tension Method of Concrete Beam Strengthened by Prestressed Fiber Cloth technical field The invention belongs to the field of building structure engineering, and in particular relates to a transverse stretching method of prestressed fiber cloth reinforced concrete beams. Background technique When concrete beams have tensile transverse cracks due to insufficient bearing capacity or external effects such as temperature changes, fatigue or impact, fiber cloth can be pasted longitudinally on the cracked surface of the beam for reinforcement to restrain the occurrence and development of transverse cracks and improve its bearing capacity. capacity and service life. Fiber cloth (especially carbon fiber) has excellent physical properties, good adhesion, durability and corrosion resistance, and has the advantages of high strength, small size, light weight, etc., and is used on the tensile surface of reinforced concrete beams It has been widely used in many aspects and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04G23/02

Inventor 周劲宇周志祥

Owner 周劲宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com