A kind of high-strength water-soluble powder coating and preparation method thereof

A water-soluble powder, high-strength technology, applied in powder coatings, fireproof coatings, coatings, etc., can solve the problems of poor thermal hardness, strength and other physical properties, and achieve simple and easy preparation methods, high bonding performance, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

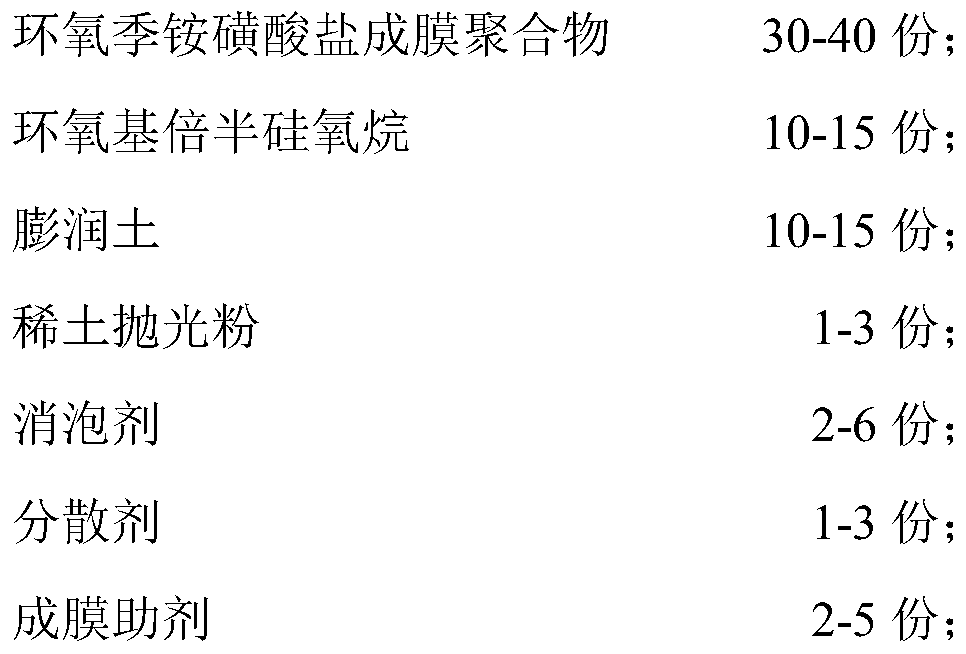

[0030] A high-strength water-soluble powder coating is composed of the following components, and the content of each component is expressed in parts by weight:

[0031]

[0032] Preferably, the preparation method of described epoxy quaternary ammonium sulfonate film-forming polymer, comprises the steps:

[0033] 1) Dissolve 11 g of triethylamine in 50 g of ethanol, add 10 g of epichlorohydrin and 3 g of potassium hydroxide, stir and react at 70° C. for 6 hours, add water to separate layers, take the organic layer and remove the solvent by rotary evaporation, Wash the crude product 4 times with diethyl ether, and then dry it in a vacuum oven at 60°C for 8 hours;

[0034] 2) Dissolve 18 g of the product prepared in step 1) in 100 g of water, add 10 g of vinylsulfonic acid and 1 g of sodium sulfate therein, stir and react at room temperature for 15 hours, then remove the water by rotary evaporation, and then use dichloro Methane dissolved product, filter and get the filtrate,...

Embodiment 2

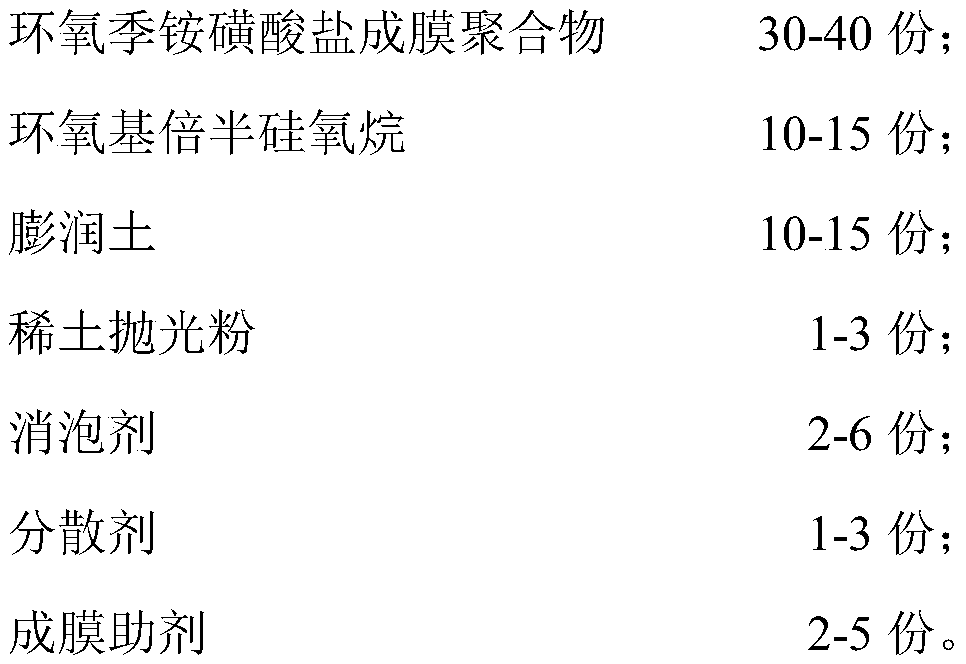

[0038] A high-strength water-soluble powder coating is composed of the following components, and the content of each component is expressed in parts by weight:

[0039]

[0040] Preferably, the preparation method of described epoxy quaternary ammonium sulfonate film-forming polymer, comprises the steps:

[0041] 1) Dissolve 11g of triethylamine in 60g of acetonitrile, add 10g of epichlorohydrin and 3.5g of sodium hydroxide to it, stir and react at 73°C for 6.5 hours, add water to separate the layers, take the organic layer and remove the solvent by rotary evaporation , and then washed the crude product with ether for 5 times, and then dried it in a vacuum oven at 64°C for 8.5 hours;

[0042] 2) Dissolve 18 g of the product prepared in step 1) in 130 g of water, add 10 g of vinylsulfonic acid and 1.5 g of sodium sulfide therein, stir and react at room temperature for 16 hours, then remove the water by rotary evaporation, and then use two Dissolve the product in methyl chlorid...

Embodiment 3

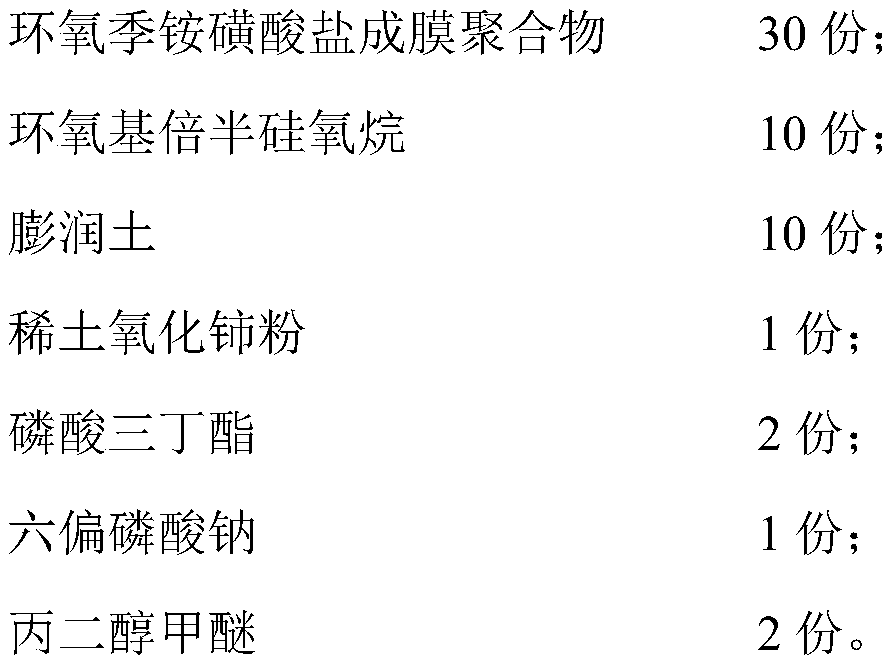

[0046] A high-strength water-soluble powder coating is composed of the following components, and the content of each component is expressed in parts by weight:

[0047]

[0048]

[0049] Preferably, the preparation method of described epoxy quaternary ammonium sulfonate film-forming polymer, comprises the steps:

[0050] 1) Dissolve 11g of triethylamine in 70g of isopropanol, add 10g of epichlorohydrin and 4g of sodium carbonate to it, stir and react at 76°C for 7 hours, add water to separate layers, take the organic layer and remove the solvent by rotary evaporation , and then washed the crude product with ether for 5 times, and then placed it in a vacuum oven at 73°C for 9 hours;

[0051] 2) 18 g of the product prepared in step 1) was dissolved in 160 g of water, and 10 g of vinylsulfonic acid and 2.3 g of ammonium thiocyanate were added thereto, stirred and reacted at room temperature for 16.5 hours, and the water was removed by rotary evaporation, and then The produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com