Red mud-based expressway base material

A base material and expressway technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as cracked road surface damage, groundwater pollution, loose red mud, etc., achieve rapid strength formation and reduce pollution , the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

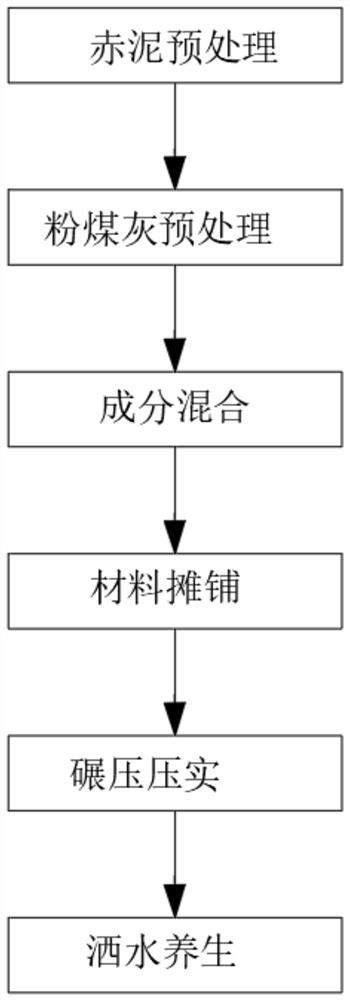

Method used

Image

Examples

Embodiment 1

[0028] 1) Take 7.5 parts of sintered red mud, put the sintered red mud into the pulverizer, start the pulverizer to pulverize the sintered red mud into solid particles with a particle size of less than 10mm, which account for more than 90% of the sintered red mud content, and then take it out ;

[0029] 2) Put the pulverized sintering red mud into the cement mixer, start the mixer and stop stirring for 5-8 hours, and introduce liquid water during the stirring process to keep the water content of the sintering red mud within 20% to 27%;

[0030] 3) Put 1.5 parts of fly ash into the pulverizer, start the pulverizer to pulverize the fly ash into a solid particle size of fly ash and keep it below 5mm, then take it out;

[0031] 4) Take out the sintering method red mud from the cement mixer, put the pulverized fly ash into the cement mixer, start the mixer and stop stirring for 5-8 hours, and introduce liquid water during the stirring process to make the fly ash water content Keep...

Embodiment 2

[0037] 1) Take 7.5 parts of sintered red mud, put the sintered red mud into the pulverizer, start the pulverizer to pulverize the sintered red mud into solid particles with a particle size of less than 10mm, which account for more than 90% of the sintered red mud content, and then take it out ;

[0038] 2) Put the pulverized sintering red mud into the cement mixer, start the mixer and stop stirring for 5-8 hours, and introduce liquid water during the stirring process to keep the water content of the sintering red mud within 20% to 27%;

[0039] 3) Take 1 portion of fly ash and put it into the pulverizer, start the pulverizer to pulverize the fly ash into a solid particle size of fly ash and keep it below 5mm, then take it out;

[0040] 4) Take out the sintering method red mud from the cement mixer, put the pulverized fly ash into the cement mixer, start the mixer and stop stirring for 5-8 hours, and introduce liquid water during the stirring process to make the fly ash water c...

Embodiment 3

[0046] 1) Take 7.5 parts of sintered red mud, put the sintered red mud into the pulverizer, start the pulverizer to pulverize the sintered red mud into solid particles with a particle size of less than 10mm, which account for more than 90% of the sintered red mud content, and then take it out ;

[0047] 2) Put the pulverized sintering red mud into the cement mixer, start the mixer and stop stirring for 5-8 hours, and introduce liquid water during the stirring process to keep the water content of the sintering red mud within 20% to 27%;

[0048] 3) Put 2 parts of fly ash into the pulverizer, start the pulverizer to pulverize the fly ash into a solid particle size of fly ash and keep it below 5mm, then take it out;

[0049] 4) Take out the sintering method red mud from the cement mixer, put the pulverized fly ash into the cement mixer, start the mixer and stop stirring for 5-8 hours, and introduce liquid water during the stirring process to make the fly ash water content Keep i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com