A kind of organic titanium ink for inkjet printing and its preparation method and application

An inkjet printing and organic titanium technology, applied in the field of building material coatings, can solve the problems of insufficient uniform thickness of titanium dioxide film, uneven thickness of nano-film, easy to fall off, etc. Uniform, low surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

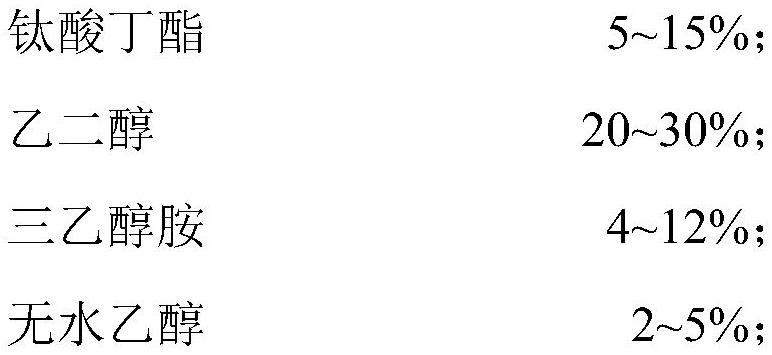

[0024] An organic titanium ink for inkjet printing, which comprises the following components in terms of raw material weight percent:

[0025]

[0026] Preparation:

[0027] 1) In the airtight section, triethanolamine is placed in the stirring device in parts by weight of raw materials, and the air humidity in the airtight section is controlled below 5%;

[0028] 2) Stir the triethanolamine evenly, add butyl titanate at a rate of 20ml / min according to the weight of raw materials during the stirring process, and continue stirring for 5min to obtain a mixture;

[0029] 3) Add ethylene glycol, absolute ethanol, diethylene glycol diether, normal tetradecane and ethylene glycol butyl ether into the mixture obtained in step 2) at a speed of 50ml / min in parts by weight of raw materials, and stir Evenly, the finished product of Example 1 is obtained, and its viscosity is measured to be 20Pa·S.

[0030] The finished product of Example 1 obtained above is printed on the surface of ...

Embodiment 2

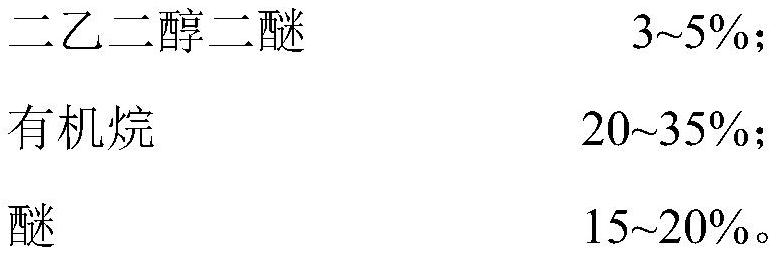

[0032] An organic titanium ink for inkjet printing, which comprises the following components in terms of raw material weight percent:

[0033]

[0034] Preparation:

[0035] 1) In the airtight section, triethanolamine is placed in the stirring device in parts by weight of raw materials, and the air humidity in the airtight section is controlled below 5%;

[0036] 2) Stir the triethanolamine evenly, add butyl titanate at a rate of 20ml / min according to the weight of raw materials during the stirring process, and continue stirring for 10min to obtain a mixture;

[0037] 3) Add ethylene glycol, absolute ethanol, diethylene glycol diether, normal tetradecane and ethylene glycol butyl ether into the mixture obtained in step 2) at a speed of 30ml / min in parts by weight of raw materials, and stir Evenly, the finished product of Example 2 is obtained, and its viscosity is measured to be 25Pa·S.

[0038] The finished product of Example 2 obtained above was printed on the surface o...

Embodiment 3

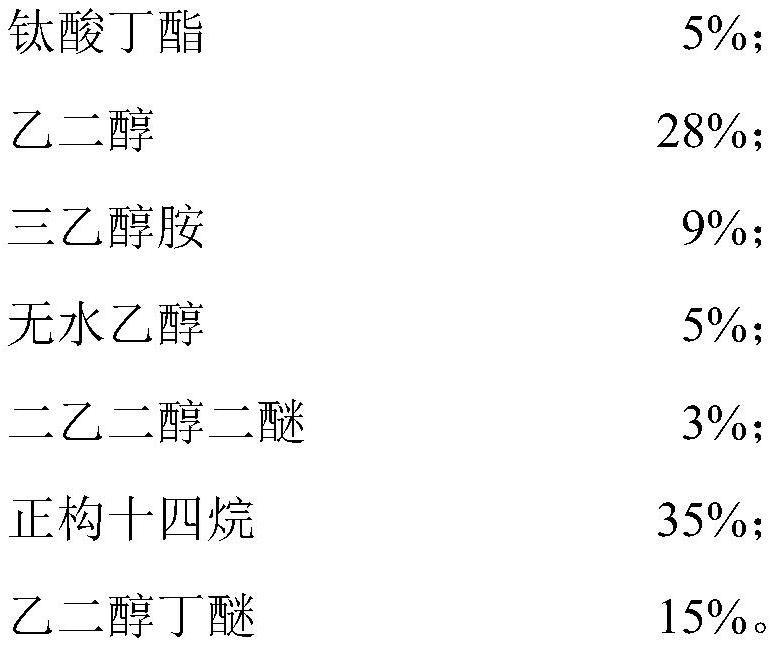

[0040] An organic titanium ink for inkjet printing, which comprises the following components in terms of raw material weight percent:

[0041]

[0042]

[0043] Preparation:

[0044] 1) In the airtight section, triethanolamine is placed in the stirring device in parts by weight of raw materials, and the air humidity in the airtight section is controlled below 5%;

[0045] 2) Stir the triethanolamine evenly, add butyl titanate at a rate of 20ml / min according to the weight of raw materials during the stirring process, and continue stirring for 7 minutes to obtain a mixture;

[0046] 3) Add ethylene glycol, absolute ethanol, diethylene glycol diether, normal tetradecane and ethylene glycol butyl ether into the mixture obtained in step 2) at a speed of 40ml / min in parts by weight of raw materials, and stir Evenly, the finished product of Example 3 is obtained, and its viscosity is measured to be 23Pa·S.

[0047]The finished product of Example 3 obtained above is printed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com