Silicon nitride ceramic slurry, silicon nitride ceramic and preparation method and application thereof

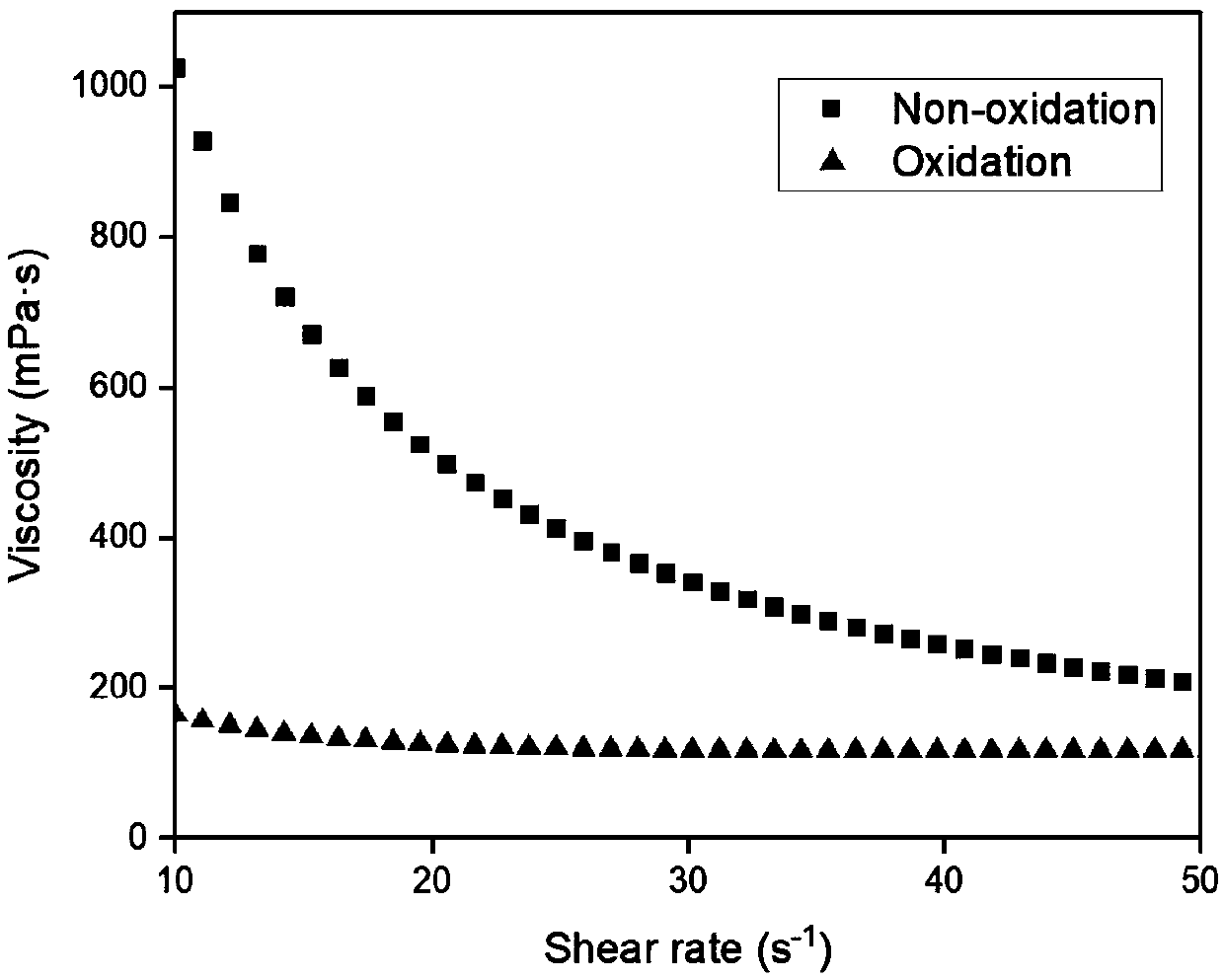

A technology of silicon nitride ceramics and silicon nitride powder, which is applied in the field of ceramic materials, can solve the problems of limiting light-curing molding technology and the development of silicon nitride ceramics, low single-layer curing depth, and scattering of silicon nitride ceramics, etc., to achieve reduction Exposure time, low cost, effect of promoting sintering densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a specific embodiment of the preparation method of silicon nitride ceramic slurry, and its preparation steps are as follows:

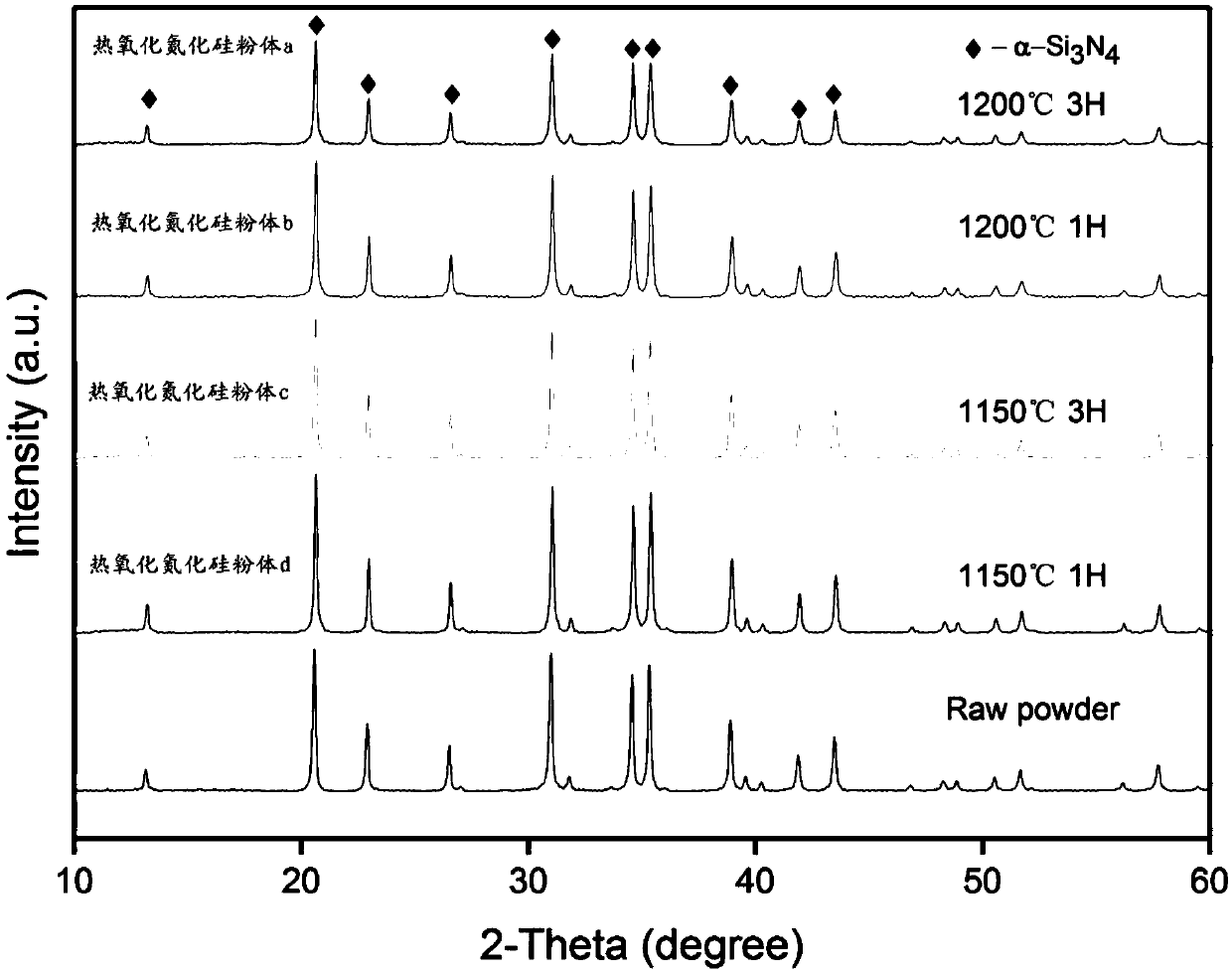

[0031] (1) Powder preparation: Put the silicon nitride powder into an air sintering furnace for oxidation treatment to obtain thermally oxidized silicon nitride powder;

[0032] (2) Powder mixing: after mixing the thermal oxidized silicon nitride powder obtained in (1) and the sintering aid powder, drying to obtain a dry powder;

[0033] (3) Slurry preparation: mix the dry powder in (2) with resin, dispersant, defoamer and photoinitiator to obtain silicon nitride ceramic slurry.

[0034] Specifically, the mixing is ball milling.

[0035] Specifically, the drying condition is drying at 60° C. for 24 hours.

[0036] Specifically, step (1) is dried and passed through a 100-mesh sieve to obtain a dry powder.

[0037] Specifically, the particle size of the thermally oxidized silicon nitride powder is 0.2-1 μm.

[0038] Spec...

Embodiment 1

[0063] The embodiment of the present invention provides the first kind of preparation method of silicon nitride ceramic slurry, and its steps are as follows:

[0064] (1) Powder preparation: put silicon nitride powder with a particle size of 0.2 μm into an air sintering furnace, raise the temperature to 1150°C at a heating rate of 5°C / min, and keep it for 2 hours to obtain thermally oxidized silicon nitride powder , to detect the SiO of the thermally oxidized silicon nitride powder of this embodiment 2 Proportions, the results are shown in Table 1;

[0065] (2) Powder mixing: 50g of thermal oxidized silicon nitride powder and 4g of Y 2 o 3 Mix by ball milling for 8 hours, dry at 60°C for 24 hours, and pass through a 100-mesh sieve to obtain a uniformly mixed dry powder;

[0066] (3) Slurry preparation: 40g of dry powder, 8.5g of 1,6-hexanediol diacrylate (HDDA), 8.5g of pentaerythritol tetraacrylate (PETTA), 0.4g of BYK-9077, 0.6 g of BYK-057 and 0.26 g of phenylbis(2,4,6-...

Embodiment 2

[0074] The embodiment of the present invention provides a second method for preparing silicon nitride ceramic slurry, the steps of which are as follows:

[0075] (1) Powder preparation: Put the silicon nitride powder with a particle size of 0.7 μm into an air sintering furnace, raise the temperature to 1300°C at a heating rate of 10°C / min, and keep it for 1h to obtain a thermally oxidized silicon nitride powder ;

[0076] (2) Powder mixing: 50g of thermally oxidized silicon nitride powder and 5g of La 2 o 3 Mix by ball milling for 8 hours, dry at 60°C for 24 hours, and pass through a 100-mesh sieve to obtain a uniformly mixed dry powder;

[0077] (3) Slurry preparation: 40g of dry powder, 8.5g of 1,6-hexanediol diacrylate (HDDA), 8.5g of trimethylolpropane triacrylate (TMPTA), 0.4g of BYK -163, 0.8g BYK-057, and 0.3g of (2,4,6-trimethylbenzoyl)diphenylphosphine oxide (TPO) were uniformly mixed to obtain a silicon nitride ceramic slurry.

[0078] The embodiment of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com