Cross-layered composite wood bamboo material and preparation method thereof

A technology for composite wood and bamboo materials, which is applied in the field of cross-laminated composite wood and bamboo materials and their preparation, can solve the problems that the mechanical properties of materials cannot be exerted, the original mechanical properties of bamboo materials are lost, the utilization rate of raw materials is low, and the like, and the Conducive to material properties, improving bamboo anisotropy, mechanical and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

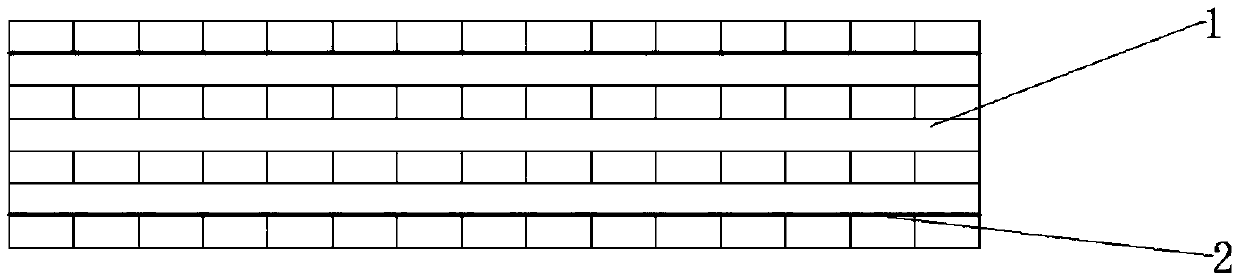

[0016] as follows figure 1 Shown, the composite wood-bamboo material of cross-lamination of the present invention comprises at least two layers of superimposed bamboo-wood laminates 1, and this bamboo-wood laminate 1 is former bamboo recombined wood, and its thickness is 20mm, and adjacent bamboo-wood laminates The fibers of 1 are arranged at 90°, and the fibers of bamboo-wood laminate 1 are arranged in one direction. A grid composite layer 2 is arranged between several bamboo and wood laminates, and the grid composite layer 2 is FRP grid reinforcement.

[0017] The specific structure can be: 1. The original bamboo recombined material-the original bamboo recombined material-the original bamboo recombined material-FRP grid reinforcement-the original bamboo recombined material... The original bamboo recombined material-the original bamboo recombined material is only in one layer of adjacent bamboo A grid composite layer 2 is arranged between the wooden laminates.

[0018] 2. R...

Embodiment 2

[0023] The cross-laminated composite wood and bamboo material of the present invention comprises at least two layers of superimposed bamboo-wood laminates 1. The bamboo-wood laminates 1 are original bamboo recombined wood and logs, and the laminate thickness of the original bamboo recombined wood is 40mm. The thickness of the bamboo-wood laminate is 40mm, the fibers of the adjacent bamboo-wood laminates are arranged at 90°, and the fibers of the bamboo-wood laminate itself are arranged in one direction. A grid composite layer 2 is arranged between several bamboo-wood laminates, and the grid composite layer 2 is a bamboo-wood fiber grid. One room of bamboo and wood laminates is equipped with a structure of bamboo and wood fiber grids, one room of adjacent bamboo and wood laminates is equipped with a structure of bamboo and wood fiber grids, or one room of several bamboo and wood laminates is equipped with bamboo and wood fiber grids structure, the bamboo-wood fiber grid can be ...

Embodiment 3

[0026] The cross-laminated composite wood and bamboo material of the present invention comprises at least two layers of superimposed bamboo-wood laminates 1. The bamboo-wood laminates 1 are composed of original bamboo recombined wood, original bamboo-glued wood, logs and log LVL. The thickness of the laminates of the bamboo recombined wood is 8mm, the thickness of the log is 10mm, the fibers of the adjacent bamboo and wood laminates 1 are arranged at 90°, the fibers of the bamboo and wood laminates 1 are arranged in one direction, and several bamboo and wood laminates 1 room A grid composite layer 2 is provided, and the grid composite layer 2 is a reinforced mesh sheet.

[0027] The specific structure can be: 1. Raw bamboo recombined wood-raw bamboo glulam-log-log LVL...raw bamboo recombined wood-raw bamboo glulam-log-log LVL Raw bamboo glulam-bamboo wood fiber grid-log-log LVL...Original bamboo recombined lumber-raw bamboo glulam-log-log LVL...Only set reinforcement mesh betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com