Extruding machine for steel claw protection semi-ring of electrolytic aluminum anode

An electrolytic aluminum anode and extruder technology, applied in turbines, mechanical equipment, engine components, etc., can solve the problems of manual removal, high labor intensity, and reduce the production cost of electrolytic aluminum, and achieve high precision and anti-reverse performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

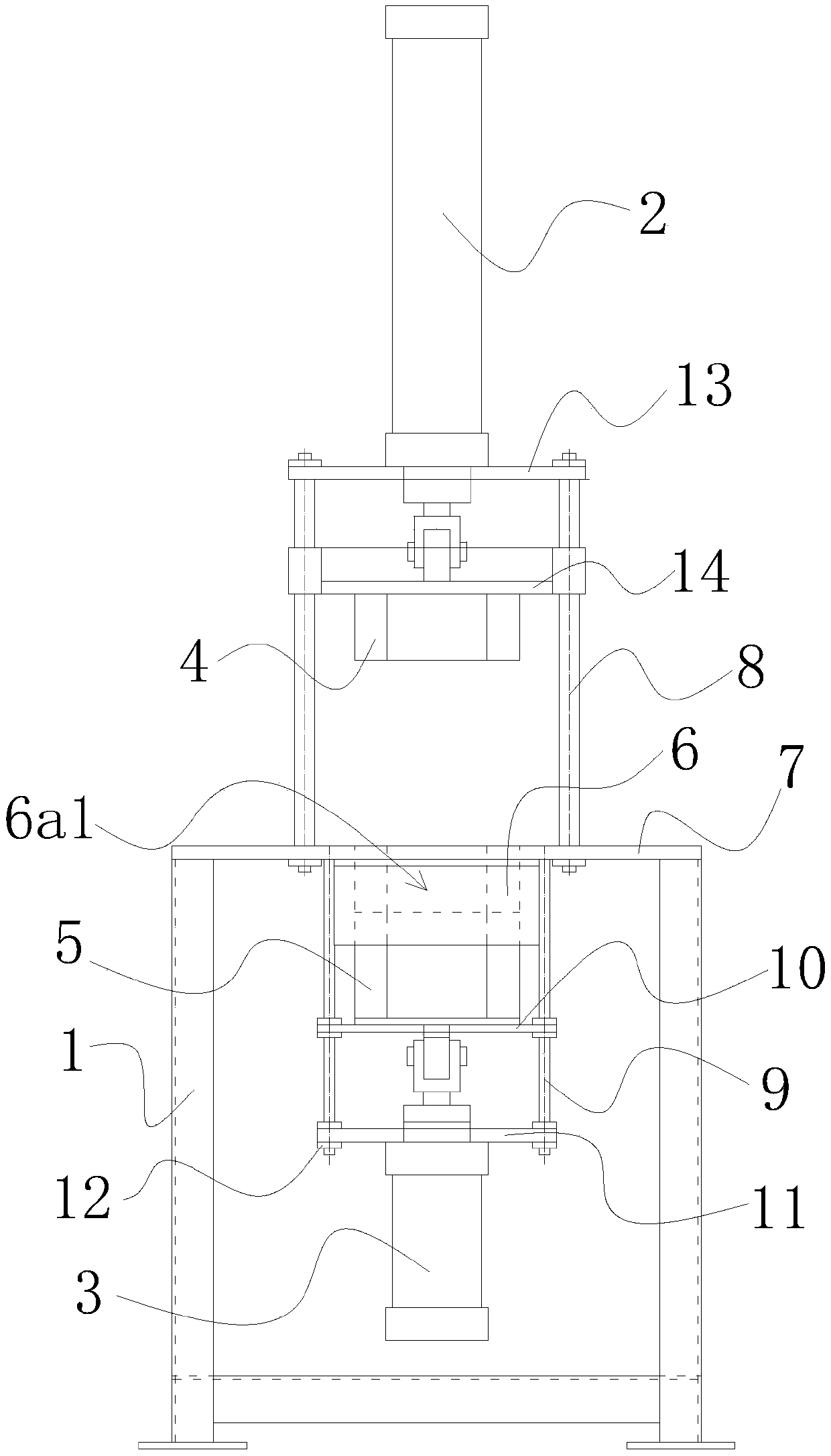

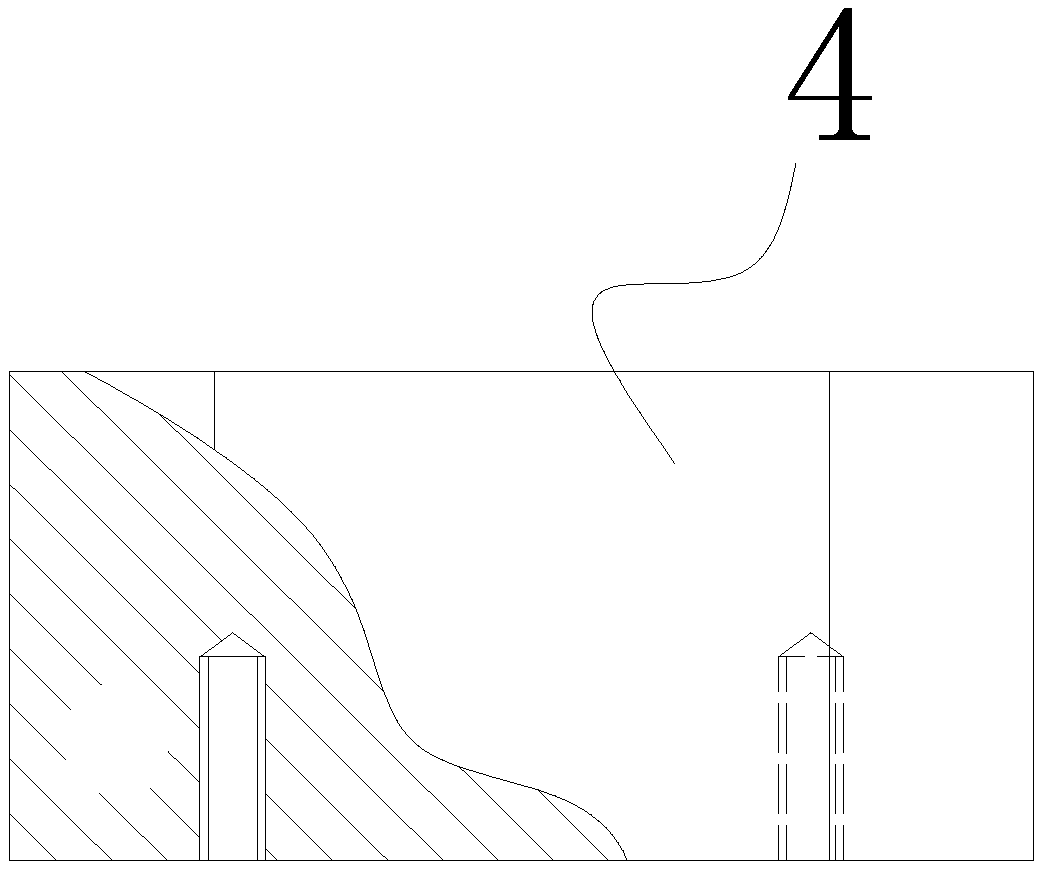

[0040] See Figure 1 to Figure 17 , Is a specific embodiment of an extruder with electrolytic aluminum anode steel claw protection half ring. The extruder of electrolytic aluminum anode steel claw protection half ring includes a mounting bracket 1, an upper hydraulic cylinder 2, a lower hydraulic cylinder 3, a pressing block 4, a top block 5 and a forming seat 6. The mounting bracket is a rectangular frame structure formed by welding multiple angle steels. The upper end of the mounting bracket 1 is fixed with a horizontal connecting plate 7 by welding. Specifically, the connecting plate is made of steel plate. The four corners of the steel plate are respectively connected to the upper ends of the four columns of the mounting bracket. welding. The middle of the connecting plate 7 is provided with a relief gap 7a, and the relief gap is in the shape of a semicircular arc with an inner diameter of 150 mm and an outer diameter of 250 mm. The connecting plate 7 is fixedly provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com