Micro/nano structure cadmium sulfide/aniline oligomer composite material preparation method

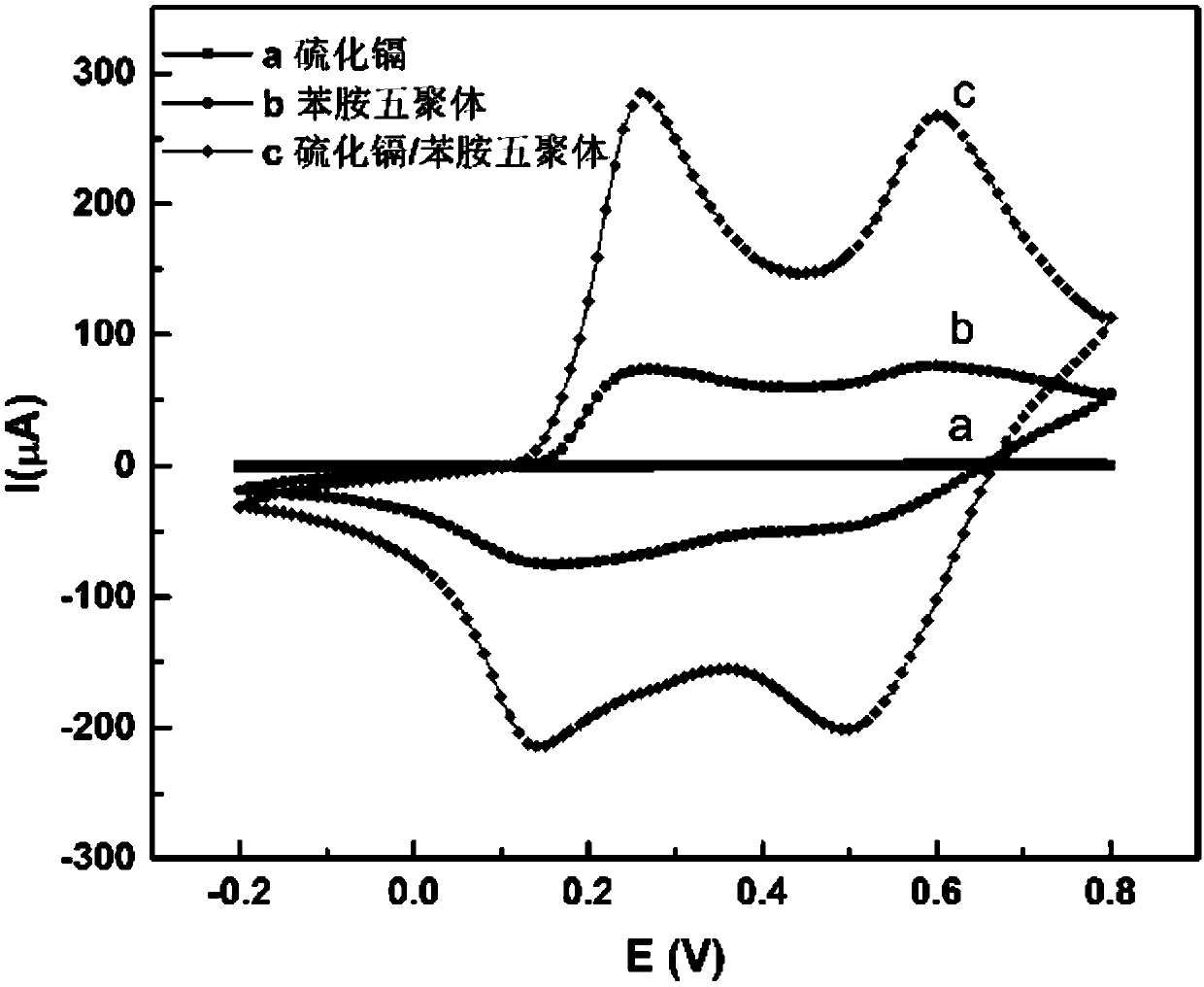

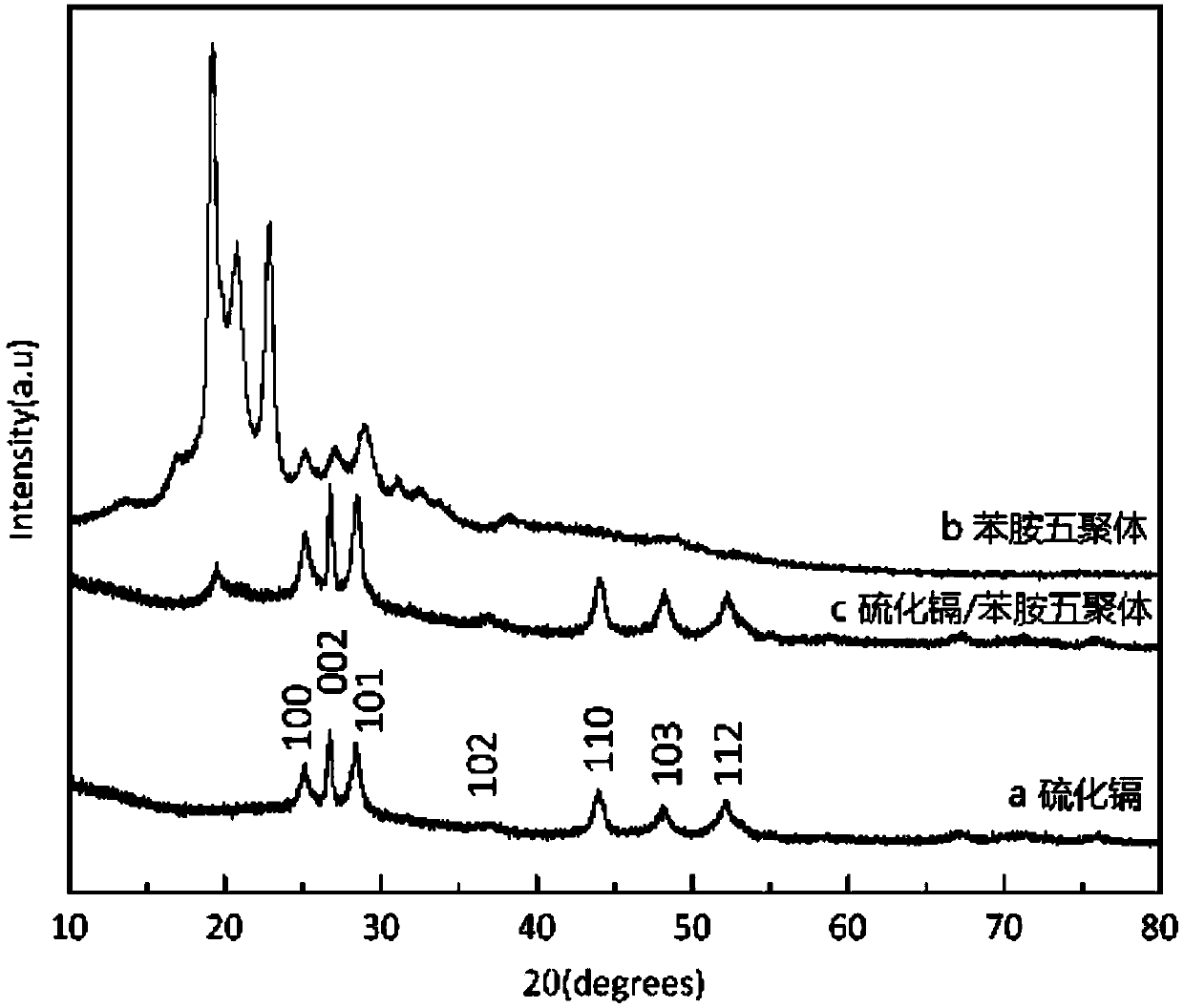

A technology of aniline oligomers and composite materials, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., to enhance photoelectric response, improve photoelectric response performance, and capacitance performance boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1, 1mmol cadmium nitrate, 2mmol thiourea, 1mmol hexamethylenetetramine are dissolved in 100ml deionized water to prepare a solution, and adjust the pH value of the solution to 10;

[0035] Step 2. Transfer the above solution to a hydrothermal reaction kettle for heating, control the temperature at 200°C, and react for 8 hours, then naturally cool to room temperature and centrifuge at a speed of 10,000r / min, and wash the precipitate obtained by centrifugation with deionized water and ethanol 10 times, after drying, cadmium sulfide nanoparticles were prepared.

[0036] Step 3. Dissolve 10 mg of cadmium sulfide nanoparticles and 10 mg of aniline pentamer in 20 ml of dimethyl sulfoxide prepared in step 2, and stir magnetically for 20 min to obtain a dispersion, centrifuge at 8000 r / min, discard For the supernatant, the precipitate was dried in a vacuum drying oven at 60° C. for 14 hours to obtain a cadmium sulfide nanoparticle / aniline pentamer composite material.

Embodiment 2

[0038] Step 1, 5mmol cadmium sulfate, 2mmol cysteine, 2mmol reduced glutathione are dissolved in 200ml deionized water to prepare a solution, and the pH value of the solution is adjusted to 8;

[0039] Step 2. Transfer the above solution to a hydrothermal reaction kettle for heating, control the temperature at 260°C, and react for 6 hours, then naturally cool to room temperature and centrifuge at a speed of 8000r / min, and wash the precipitate obtained by centrifugation with deionized water and ethanol 10 times, after drying, cadmium sulfide microsheets were obtained.

[0040] Step 3. Dissolve 20 mg of cadmium sulfide microflakes and 10 mg of aniline tetramer in 50 ml of N,N-dimethylformamide prepared in step 2. After ultrasonication for 15 minutes, a dispersion is prepared, and centrifuged at 10,000 r / min. , discarding the supernatant, and drying the precipitate in an oven at 80°C for 8 hours to obtain a cadmium sulfide microsheet / aniline tetramer composite material;

Embodiment 3

[0042]Step 1, 1mmol cadmium nitrate, 1mmol cysteine, 1mmol hexamethylenetetramine are dissolved in 100ml deionized water to prepare a solution, and adjust the pH value of the solution to 7;

[0043] Step 2. Transfer the above solution to a hydrothermal reaction kettle for heating, control the temperature at 200°C, react for 4 hours, cool to room temperature naturally and centrifuge at a speed of 12000r / min, and wash the precipitate obtained by centrifugation with deionized water and ethanol 10 times, after drying, cadmium sulfide micron particles were obtained.

[0044] Step 3, 10 mg of cadmium sulfide micron particles prepared in step 2, 10 mg of aniline heptamer were dissolved in 10 ml of ethanol, magnetically stirred for 30 min to obtain a dispersion, centrifuged at 8000 r / min, discarded the supernatant, The precipitate was dried in a vacuum oven at 50°C for 12 hours to obtain a cadmium sulfide microparticle / aniline heptamer composite material;

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com