Nanosheets-assembled Co dendrite electrocatalyst material and preparation method thereof

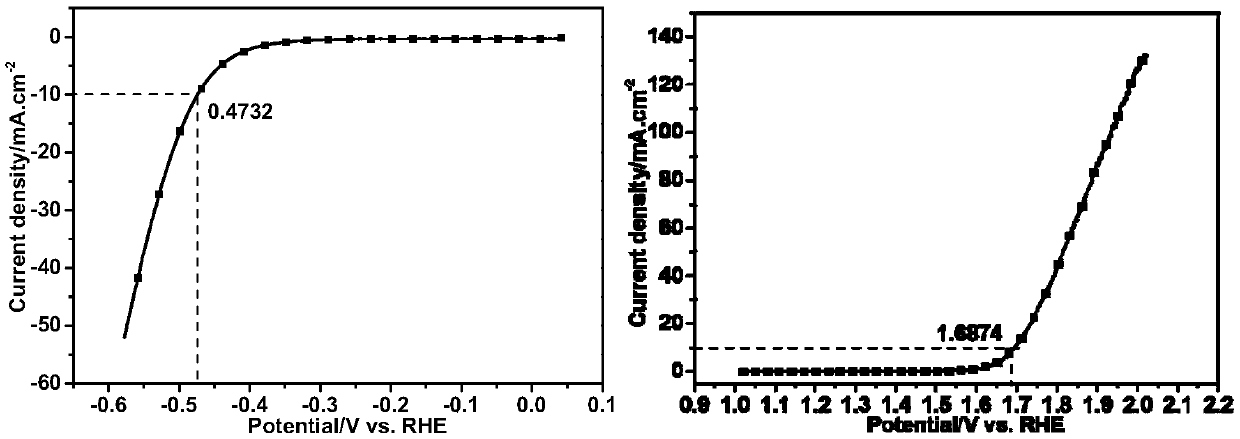

An electrocatalyst and nanosheet technology, which is applied in the field of Co dendritic electrocatalyst materials and their preparation, can solve the problems of low surface area, insufficient exposure of active sites, and low catalytic activity of bulk Co catalyst materials, and achieve excellent electrolysis of hydrogen and Oxygen evolution performance, promotion of electrolytic hydrogen evolution and oxygen evolution process, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a Co dendritic electrocatalyst material assembled by nanosheets, comprising the following steps:

[0042] (1) Weigh 9.0g deionized water, 0.4g cobalt chloride hexahydrate, stir at room temperature until the cobalt chloride hexahydrate dissolves, and the solution is gray-green;

[0043] (2) In the mixed homogeneous solution obtained in step (1), after adding 0.5 g of sodium hydroxide, the solution gradually changes from gray green to dark blue during the stirring process, and then quickly turns pink, and then adds 1 g of the solution after the solution is uniform. Hydrazine hydrate, stirred until the solution is uniform;

[0044] (3) Pour the prepared solution into a clean reaction kettle, and react at 150 degrees Celsius for 0.5 hours.

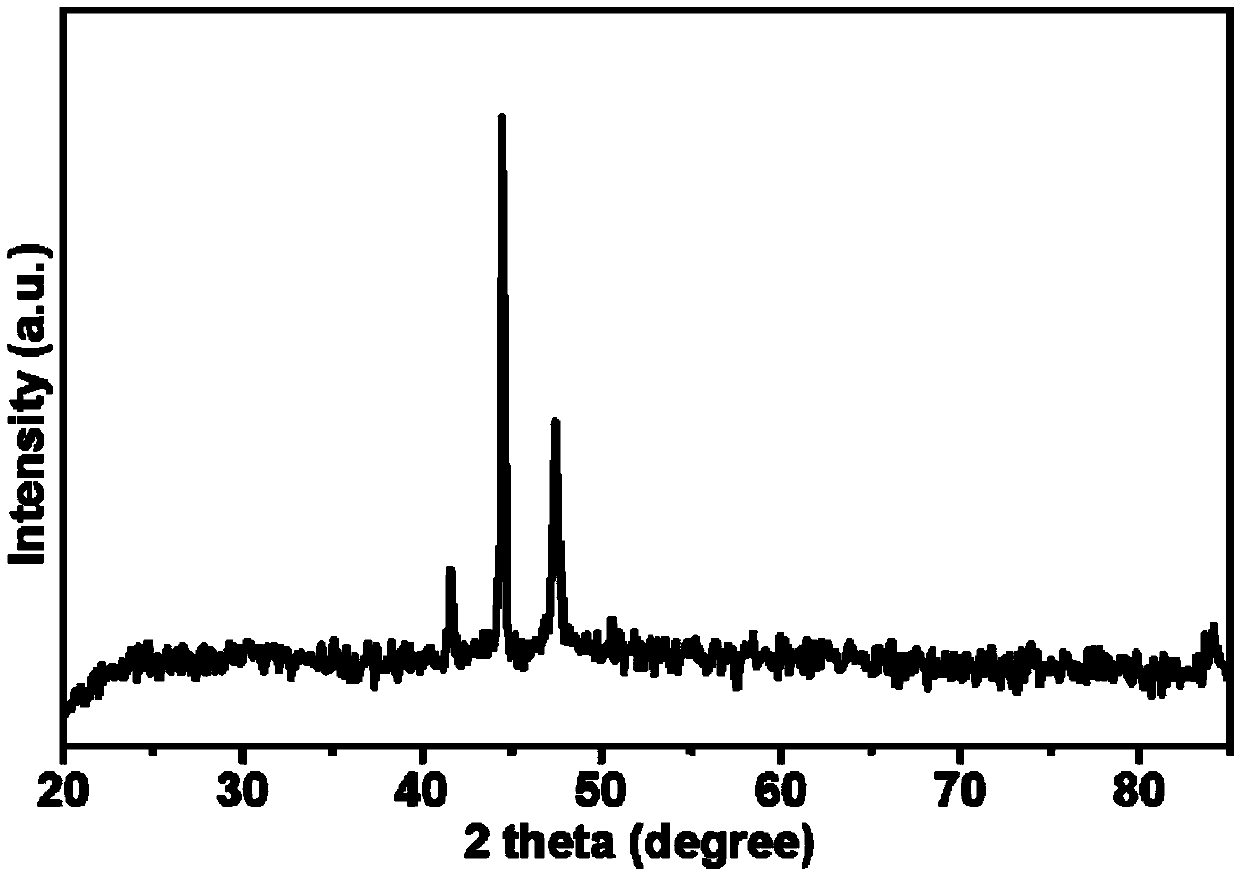

[0045] The X-ray diffraction pattern of the Co dendritic electrocatalyst material assembled by nanosheets is shown in figure 1 . Scanning electron microscope image see figure 2 , the results of scanning elec...

Embodiment 2

[0047] A preparation method of a Co dendritic electrocatalyst material assembled by nanosheets, comprising the following steps:

[0048] (1) Weigh 9.0g deionized water, 0.4g cobalt chloride hexahydrate, stir at room temperature until the cobalt chloride hexahydrate dissolves, and the solution is gray-green;

[0049] (2) In the mixed homogeneous solution obtained in step (1), after adding 0.5 g of sodium hydroxide, the solution gradually changes from gray green to dark blue during the stirring process, and then quickly turns pink, and then adds 1 g of the solution after the solution is uniform. Hydrazine hydrate, stirred until the solution is uniform;

[0050] (3) Pour the prepared solution into a clean reaction kettle, and react for 2 hours at 150 degrees Celsius.

[0051] The X-ray diffraction pattern of the Co dendritic electrocatalyst material assembled by nanosheets is shown in Figure 4 . The results of scanning electron microscope analysis show that the product is a d...

Embodiment 3

[0053] A preparation method of a Co dendritic electrocatalyst material assembled by nanosheets, comprising the following steps:

[0054] (1) Weigh 9.0g deionized water, 0.4g cobalt chloride hexahydrate, stir at room temperature until the cobalt chloride hexahydrate dissolves, and the solution is gray-green;

[0055](2) In the mixed homogeneous solution obtained in step (1), after adding 0.5 g of sodium hydroxide, the solution gradually changes from gray green to dark blue during the stirring process, and then quickly turns pink, and then adds 1 g of the solution after the solution is uniform. Hydrazine hydrate, stirred until the solution is uniform;

[0056] (3) Pour the prepared solution into a clean reaction kettle, and react for 1 hour at 200 degrees Celsius.

[0057] The X-ray diffraction pattern of the Co dendritic electrocatalyst material assembled by nanosheets is shown in Figure 7 . The results of scanning electron microscope analysis show that the product is a den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com