A kind of oil-water separation omentum and its preparation method and application

A technology for oil-water separation omentum and oil-water separation, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of poor feasibility, high cost, cumbersome preparation process, etc., and achieve improved utilization efficiency, good hydrophilic Oily, anti-penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of preparation method of oil-water separation omentum, comprises the steps:

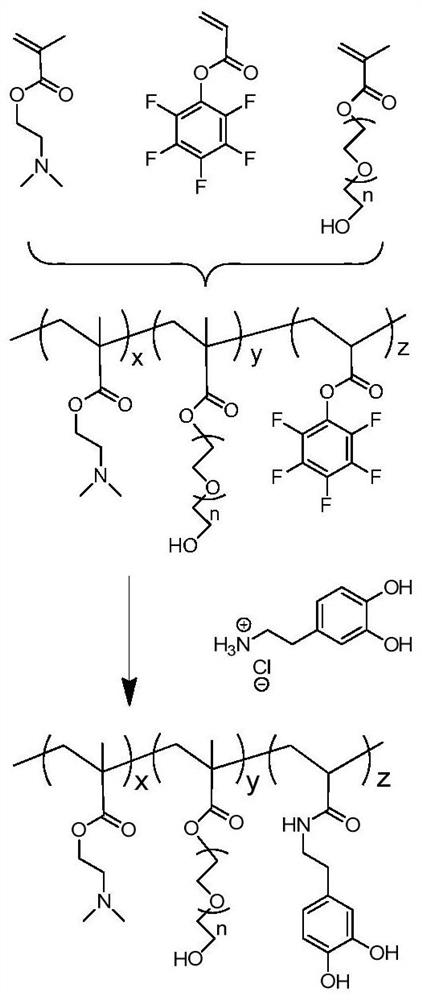

[0044] (1) Synthesis of copolymers containing polyethylene glycol hydrophilic chains, dimethylaminoethyl hydrophobic chains and mussel biomimetic catechol groups;

[0045] Synthetic route such as figure 1 As shown, in the first step, dimethylaminoethyl methacrylate (1.57g), poly(ethylene glycol) methacrylate (4.75g), pentafluorophenol acrylate (2.38g), RAFT reagent 2- (Dodecyltrithiocarbonate)-2-methylpropionic acid (0.40g) was dissolved in 30mL 1,4-dioxane, stirred for 20min under nitrogen gas; adding the initiator azobisisobutyronitrile (0.04g), stirred for 10 min under the protection of nitrogen to obtain the first reaction system; transferred the first reaction system to a 72 °C oil bath and stirred for 3-4 h to obtain the second reaction system; the second reaction system was spun at 60 °C After evaporation and concentration, it was slowly dropped into n-hexane, and the product I...

Embodiment 2

[0058] (1) Synthesis of copolymers containing polyethylene glycol hydrophilic chains, dimethylaminoethyl hydrophobic chains and mussel biomimetic catechol groups;

[0059] Synthetic route such as figure 1 As shown, in the first step, dimethylaminoethyl methacrylate (3.14g), poly(ethylene glycol) methacrylate (9.5g), pentafluorophenol acrylate (4.76g), RAFT reagent 2- (Dodecyltrithiocarbonate)-2-methylpropionic acid (0.20g) was dissolved in 60 mL of 1,4-dioxane, stirred for 20min under nitrogen protection; the initiator azobis Isobutyronitrile (0.02g), stirred with nitrogen gas for 10min to obtain the first reaction system; transferred the first reaction system to a 72°C oil bath and stirred for 3~4h to obtain the second reaction system; the second reaction system was spun at 60°C After evaporation and concentration, it was slowly dropped into n-hexane, and the product I was precipitated.

[0060] In the second step, dissolve the obtained product I in 60 mL of dichloromethane...

Embodiment 3

[0070] (1) Synthesis of copolymers containing polyethylene glycol hydrophilic chains, dimethylaminoethyl hydrophobic chains and mussel biomimetic catechol groups;

[0071]In the first step, dimethylaminoethyl methacrylate (2.36g), poly(ethylene glycol) methacrylate (7.13g), pentafluorophenol acrylate (3.57g), RAFT reagent 2-(12 Alkyl trithiocarbonate group)-2-methylpropionic acid (0.40) was dissolved in 45 mL 1,4-dioxane, stirred for 20 min under nitrogen protection; adding initiator azobisisobutyronitrile ( 0.04g), stirred with nitrogen for 10 min to obtain the first reaction system; transferred the first reaction system to a 72°C oil bath and stirred for 3-4 h to obtain the second reaction system; the second reaction system was concentrated by rotary evaporation at 60°C Afterwards, it was slowly dropped into n-hexane, and the product I was precipitated.

[0072] In the second step, dissolve the obtained product I in 45mL of dichloromethane, add dopamine hydrochloride (5.70g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com