Special stabilizing agent for normal temperature fermented soybean milk and applications thereof

A sour soy milk and stabilizer technology, applied to bacteria and milk substitutes used in applications and food preparations, can solve problems such as insufficient flavor, short shelf life, damage to the texture and tissue state of sour soy milk, and achieve the removal of beany smell , The effect of prolonging the storage period at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

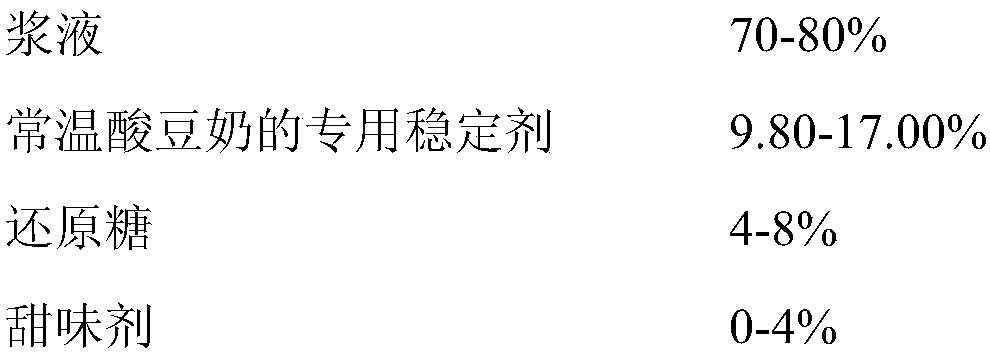

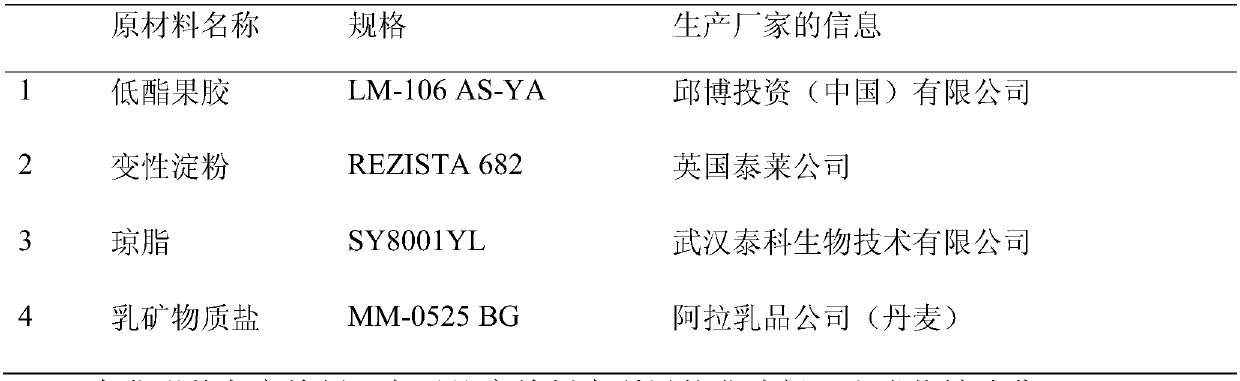

[0047] A special stabilizer for soy milk at normal temperature, calculated in parts by weight, its raw material composition and content are as follows:

[0048]

[0049] The preparation method of the special stabilizer of above-mentioned a kind of room temperature soy milk, concrete steps are as follows:

[0050] Add low-ester pectin, agar, modified starch and milk mineral salt in sequence in the container, and then mechanically stir and mix to obtain a special stabilizer for soy milk at room temperature.

[0051] The above-mentioned special stabilizer for sour soy milk at normal temperature is used for the preparation of soy milk at normal temperature, and the specific process of its preparation includes the following steps:

[0052] (1), according to the mass ratio of soybeans: pure water is 1:2, add soybeans to purified water, and then add NaHCO 3 , after stirring evenly, stand still at room temperature for 6 hours, then filter and remove the filtrate to obtain soaked s...

Embodiment 2

[0067] A special stabilizer for soy milk at normal temperature, calculated in parts by weight, its raw material composition and content are as follows:

[0068]

[0069] The preparation method of the special stabilizer of above-mentioned a kind of room temperature soy milk is the same as embodiment 1.

[0070] The above-mentioned special stabilizer for sour soy milk at normal temperature is used for the preparation of soy milk at normal temperature, and the specific process of its preparation includes the following steps:

[0071] (1), according to the mass ratio of soybeans: pure water is 1:3, add soybeans to purified water, and then add NaHCO 3 , after stirring evenly, stand still at room temperature for 16 hours, then filter and remove the filtrate to obtain soaked soybeans;

[0072] above NaHCO 3 The amount of addition, according to NaHCO 3 : The mass ratio of pure water is 1.20:100;

[0073] (2) According to the mass ratio of soaked soybeans: pure water is 1:6, add...

Embodiment 3

[0086] A special stabilizer for soy milk at normal temperature, calculated in parts by weight, its raw material composition and content are as follows:

[0087]

[0088] The preparation method of the special stabilizer of above-mentioned a kind of room temperature soy milk is the same as embodiment 1.

[0089] The above-mentioned special stabilizer for sour soy milk at normal temperature is used for the preparation of soy milk at normal temperature, and the specific process of its preparation includes the following steps:

[0090] (1), according to the mass ratio of soybeans: pure water is 1:2.5, add soybeans to purified water, and then add NaHCO 3 , after stirring evenly, stand still at room temperature for 10 hours, then filter and remove the filtrate to obtain soaked soybeans;

[0091] above NaHCO 3 The amount of addition, according to NaHCO 3 : The mass ratio of pure water is 0.80:100;

[0092] (2) According to the mass ratio of soaked soybeans: pure water is 1:5.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com