An assembly line for separating duck gizzard and duck gland gastroesophagus

A gastroesophageal and assembly line technology, applied in the field of poultry processing equipment, can solve the problems of reducing product yield, wasting water resources, and high manual operation costs, and achieve the effects of reducing operation difficulty, reducing cross-contamination, and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

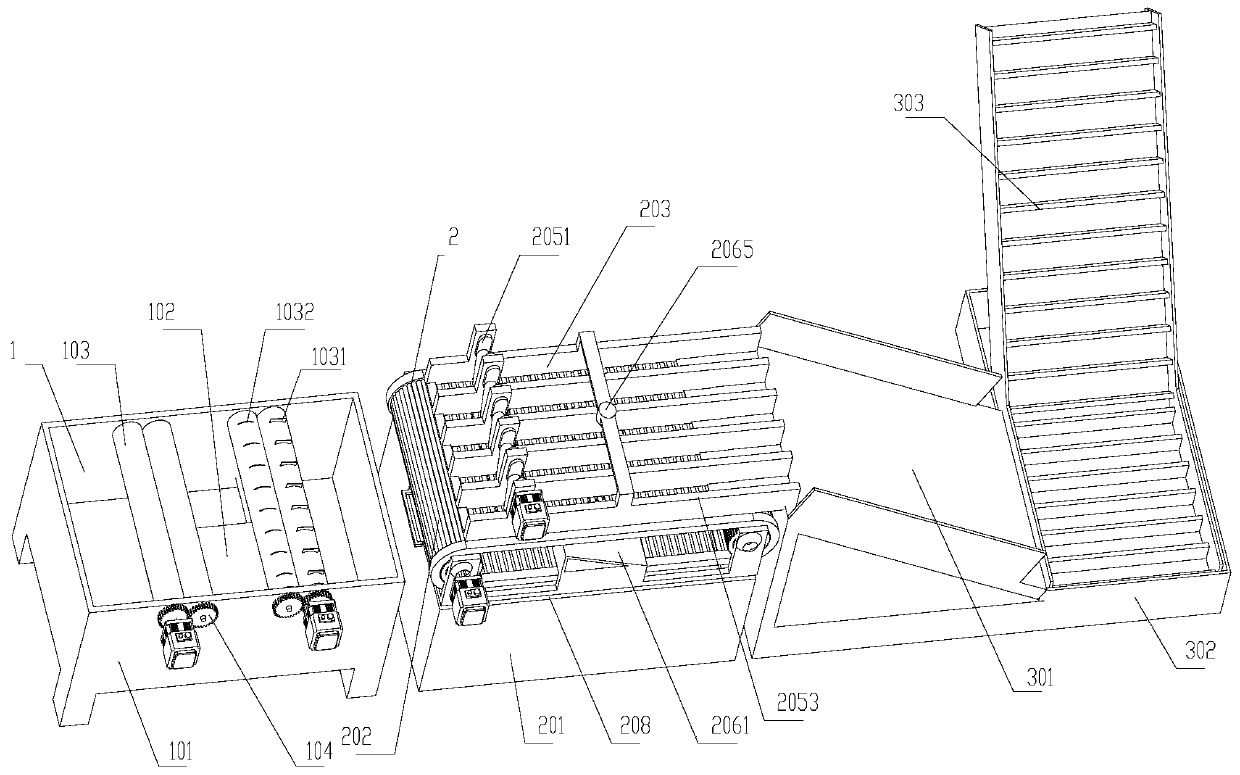

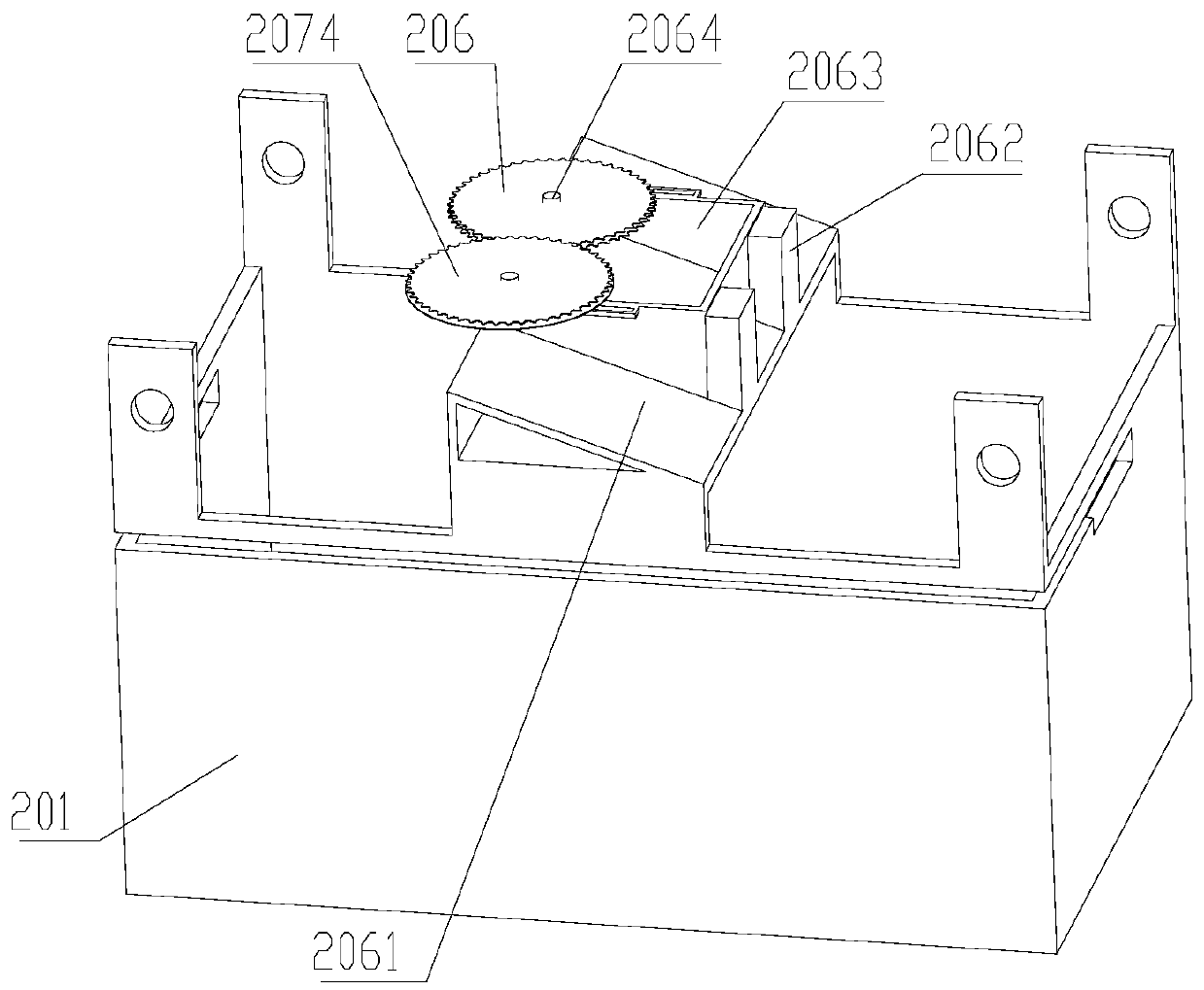

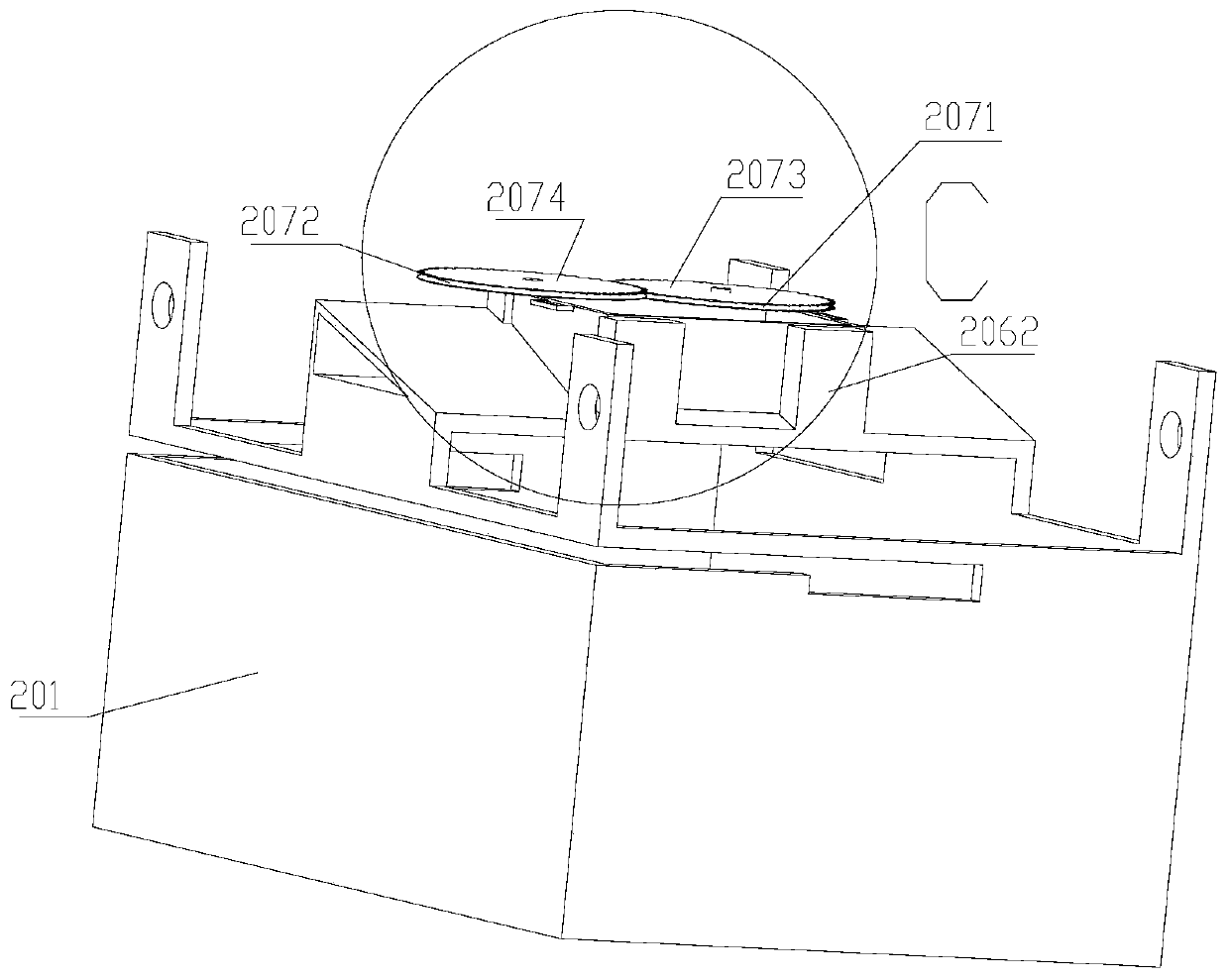

[0035] see Figure 1 to Figure 6 , the present invention provides a duck gizzard and duck gland gastroesophageal separation assembly line, including duck gland gastroesophageal content cleaning mechanism 1, duck gizzard and duck gland gastroesophageal content cleaning mechanism 1 side is provided with duck gizzard and duck gland gastroesophageal separation mechanism 2 ;

[0036] The duck gland, stomach and esophagus content cleaning mechanism 1 includes a cleaning pool 101, and the inner bottom of the cleaning pool 101 is provided with an ultrasonic vibration plate 102; Group;

[0037] Both the clamping roller group and the cutting roller group include two rollers 103 arranged side by side, each roller 103 is provided with a gear 104 on the shaft, and the corresponding gear 104 of the two rollers 103 of the same group meshing with each other, one of the gears 104 of each roller set is coaxial with a motor output shaft;

[0038] The outer surface of one of the rotating rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com