High gain and high power density converter and commutation method for high and low voltage sides thereof

A high-power density, high-voltage side technology, applied in the field of converters, can solve the problems of complex coupled inductor process implementation, large current stress of power switch tubes, and not wide voltage adjustment range, so as to improve efficiency, power density, and reliability , The effect of reducing the volume of the magnetic core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be described in detail below.

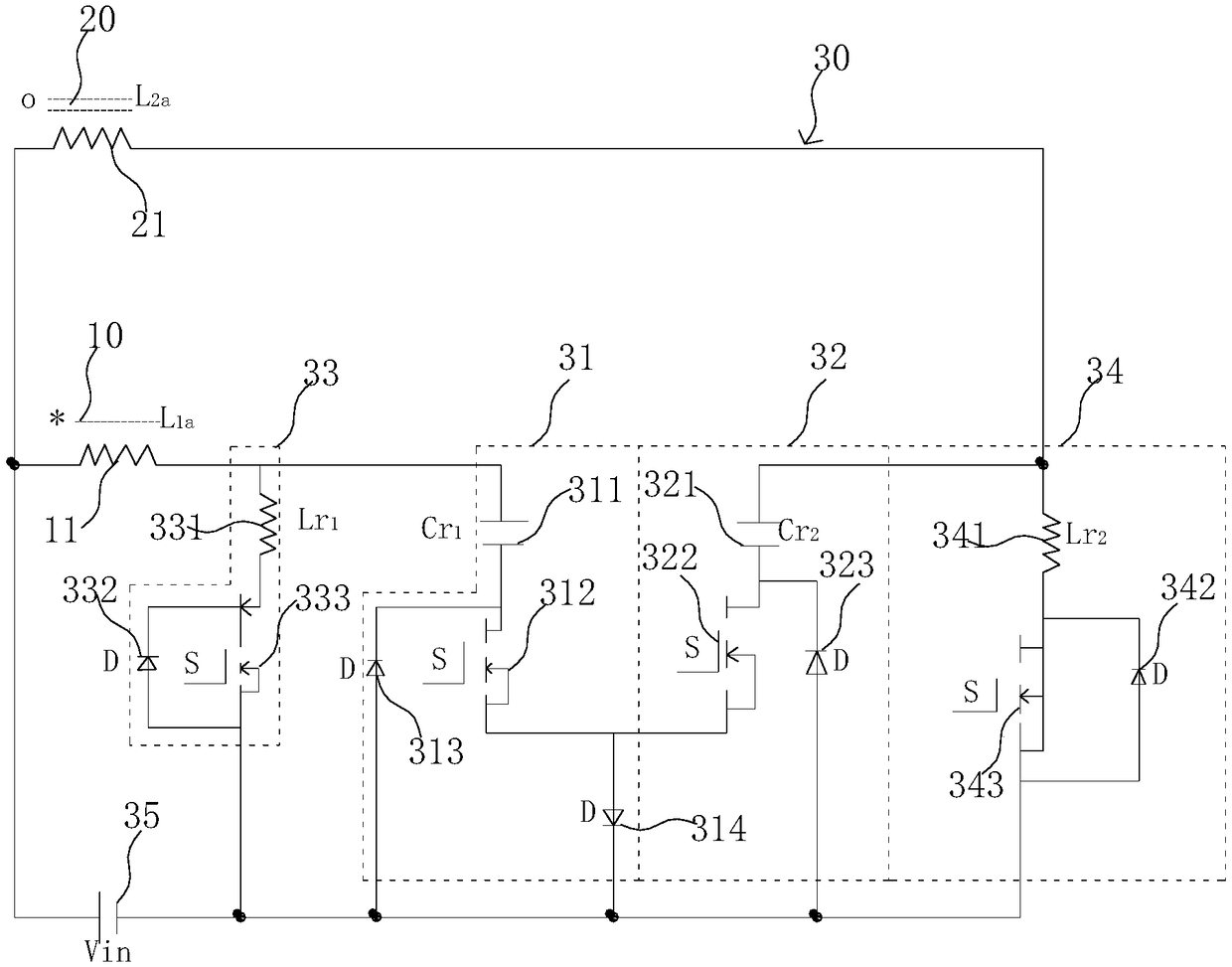

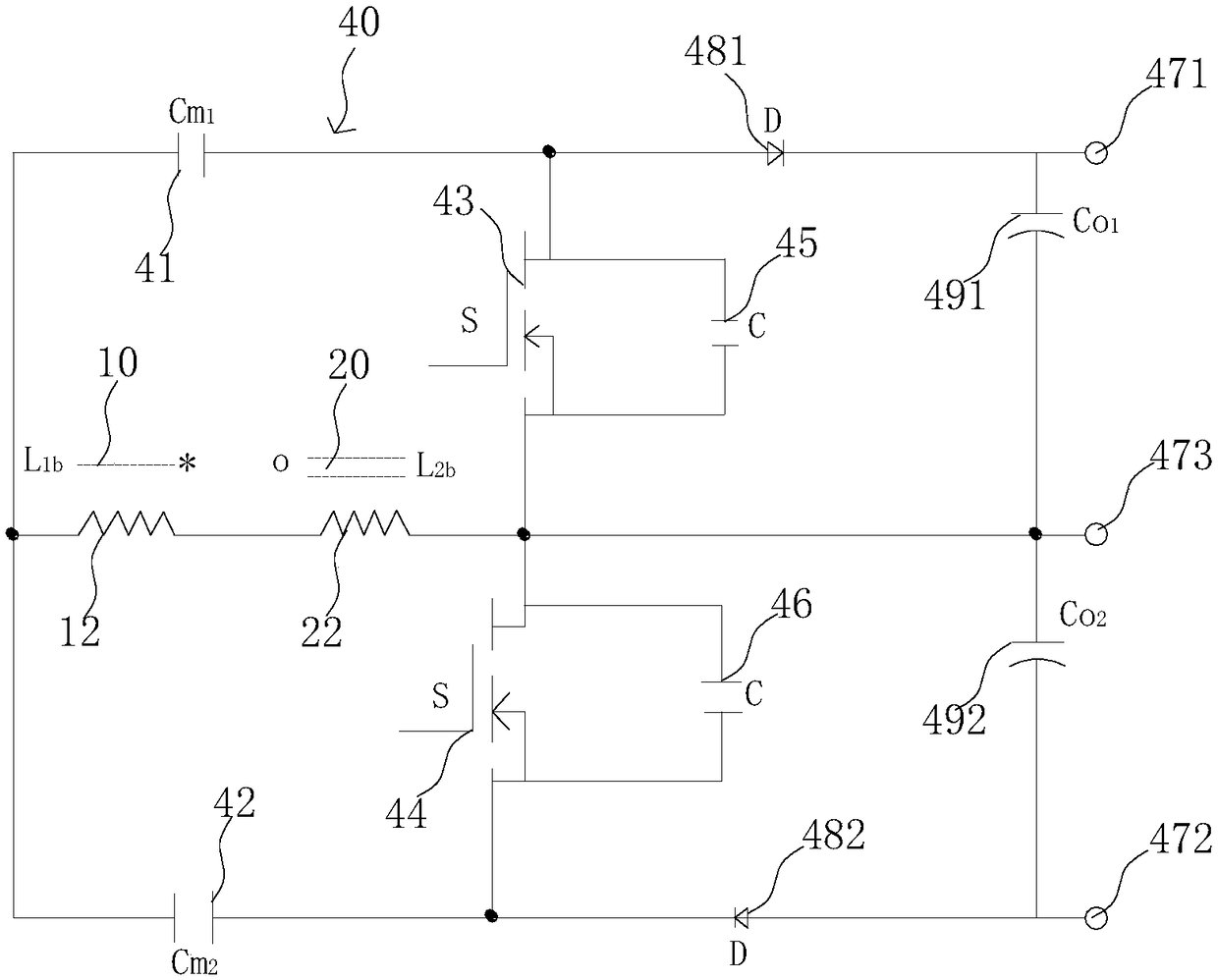

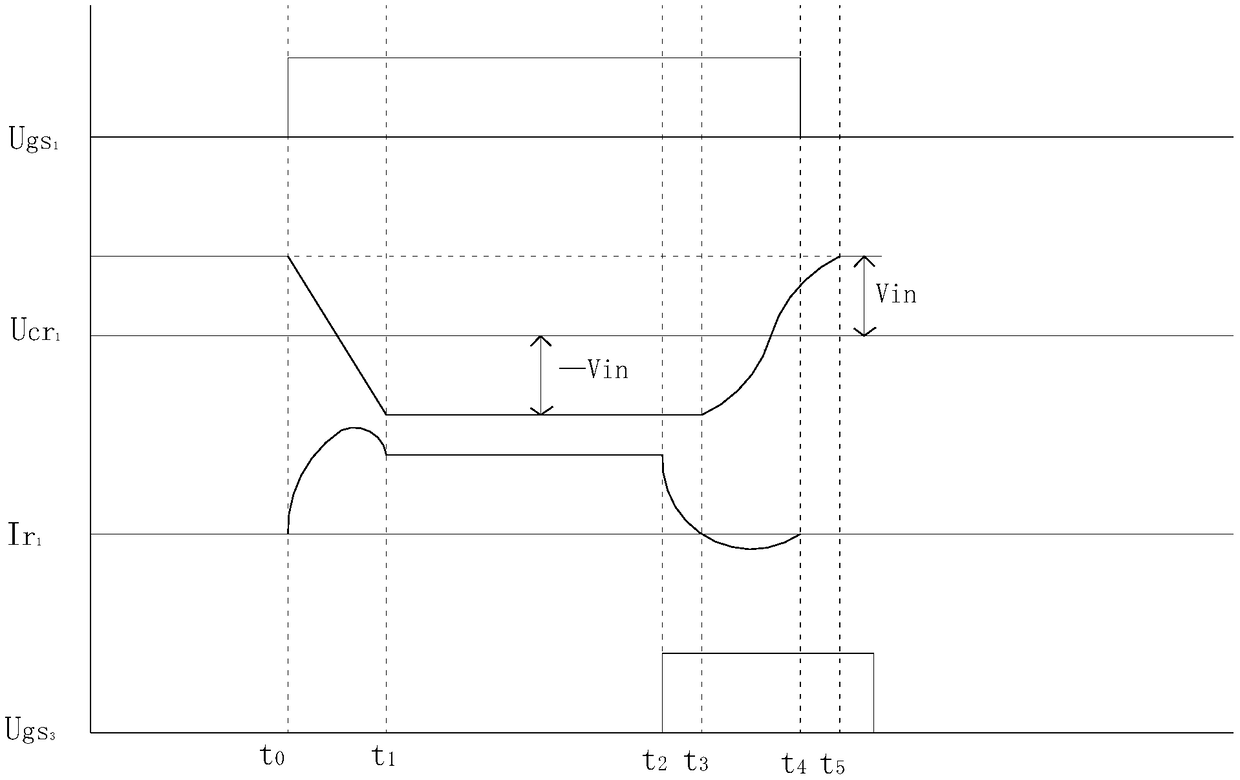

[0053] Such as figure 1 , figure 2 As shown, the high-gain high-power-density converter includes a first group of coupled inductors 10, a second group of coupled inductors 20, a converter low-voltage side circuit 30, and a converter high-voltage side circuit 40. The first group of coupled inductors 10 includes a first low-voltage side winding 11, the first high-voltage side winding 12, the second group of coupled inductors 20 includes the second low-voltage side winding 21, the second high-voltage side winding 22; the converter low-voltage side circuit 30 includes the first quasi-resonant soft switching circuit 31, the second Quasi-resonant soft switching circuit 32, first low-voltage branch 33, second low-voltage branch 34, low-voltage power supply 35, the end of the same name of the first low-voltage side winding 11 and the second low-voltage side winding 21 are respectively connected to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com