Miniature ultra-wideband common mode noise suppression circuit

A common mode noise and suppression circuit technology, applied in circuits, electrical components, waveguide devices, etc., can solve the problems of deteriorating common mode noise suppression effect, inability to adapt, large size, etc., to maintain signal integrity and ensure signal integrity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

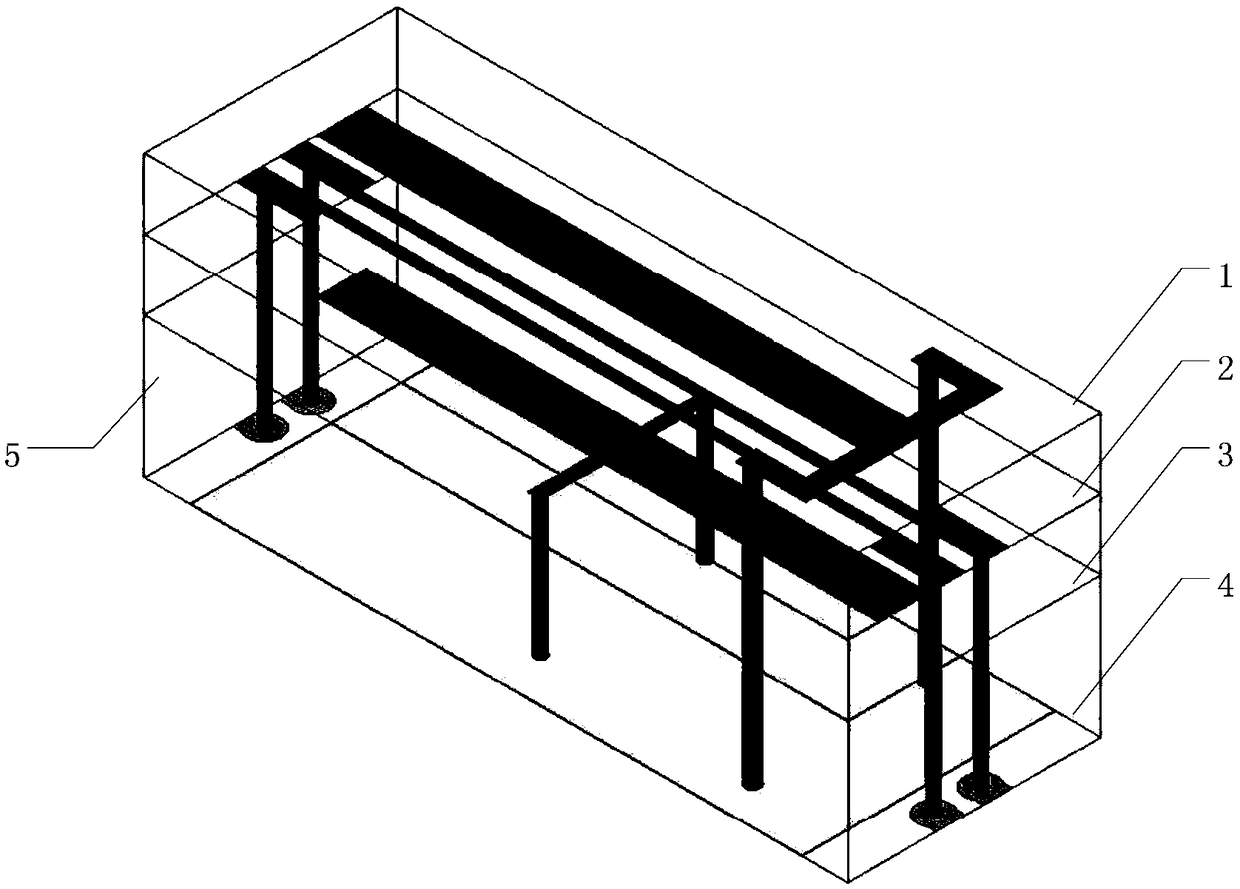

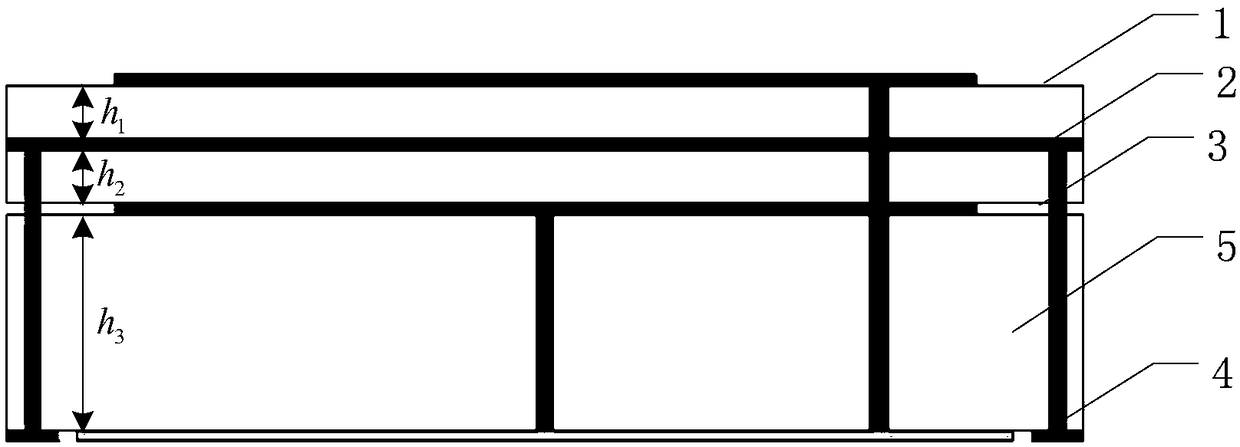

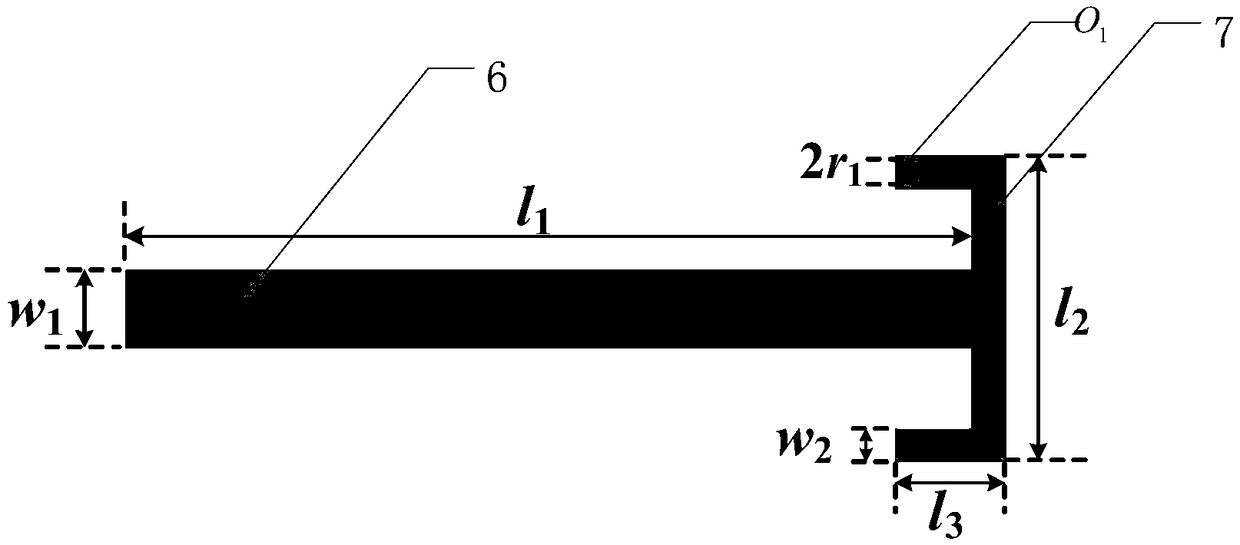

[0020] The common mode noise suppression circuit provided in this embodiment adopts multi-layer circuit technology, such as figure 1 and figure 2 Shown are the three-dimensional structural schematic diagram and side view of the common mode noise suppression circuit, respectively. The common mode noise suppression circuit has a four-layer circuit structure, all of which are made of metal, and copper / silver with less loss can be used to realize the actual circuit. The four-layer circuit includes a quarter-wavelength stepped impedance resonator layer 1, an embedded differentially coupled microstrip line layer 2, a half-wavelength resonator layer 3, and a reference ground layer 4; each layer is separated by a dielectric substrate 5; in this embodiment The LTCC process is adopted in the medium, the dielectric material is Dupont 951, and the relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com