Battery carbon dust feeding device

A technology of toner and battery, applied in the field of battery into toner device, which can solve problems such as inconvenient use, cumbersome manufacturing process, and insufficient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

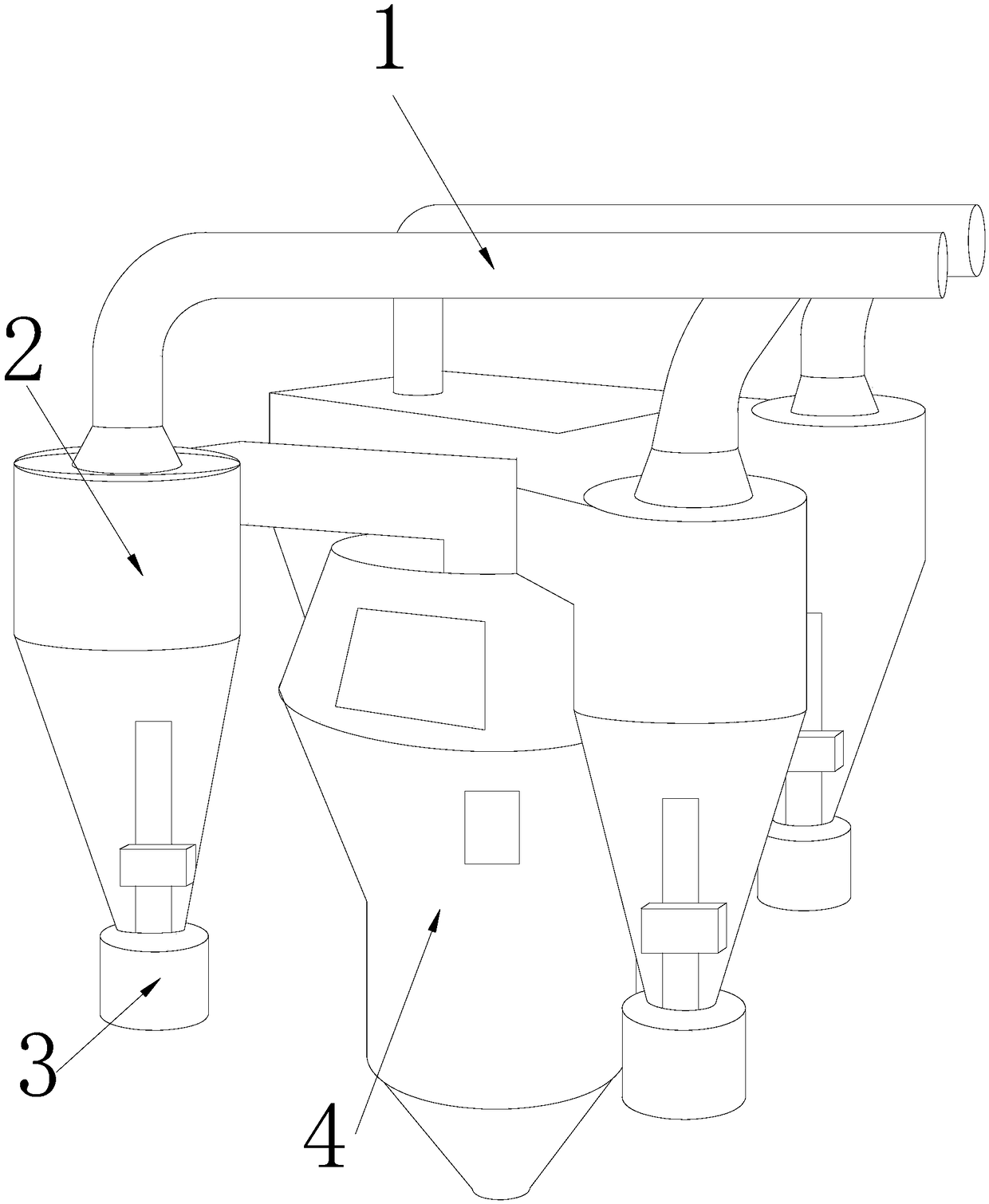

[0026] see Figure 1-Figure 4 , the invention provides a battery into carbon powder device: its structure includes a powder guide pipe 1, a powder feeder head 2, a compacting device 3, a control body 4;

[0027] The powder guide pipe 1 is connected to the powder feeder head 2 above, and the powder feeder head 2 is connected to the control body 4 on the outside and connected to the compacting device 3, and the compacting device 3 is installed on the powder feeder The bottom of the head 2 is movably connected, and the control body 4 is controlled and connected to the control body 4;

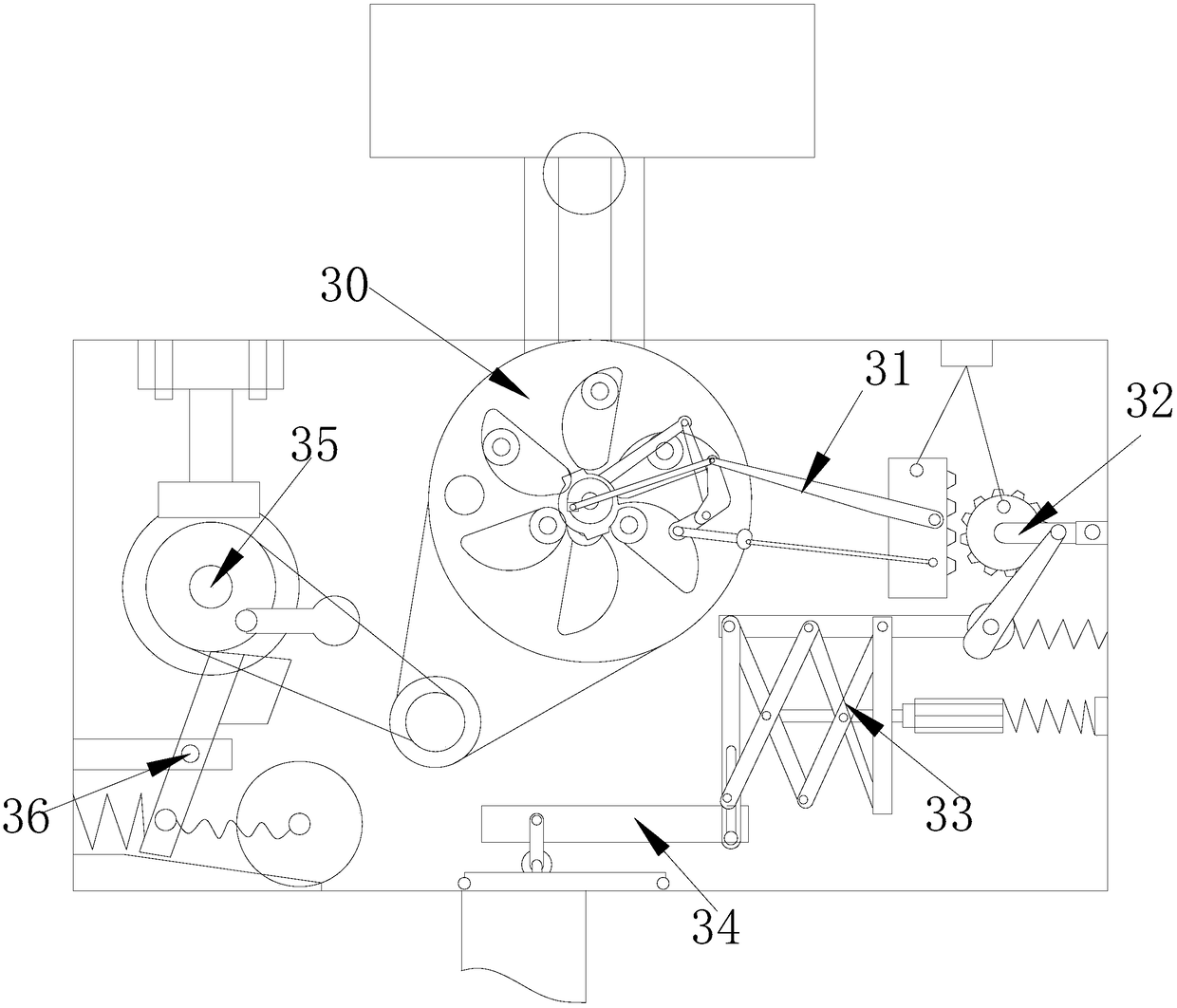

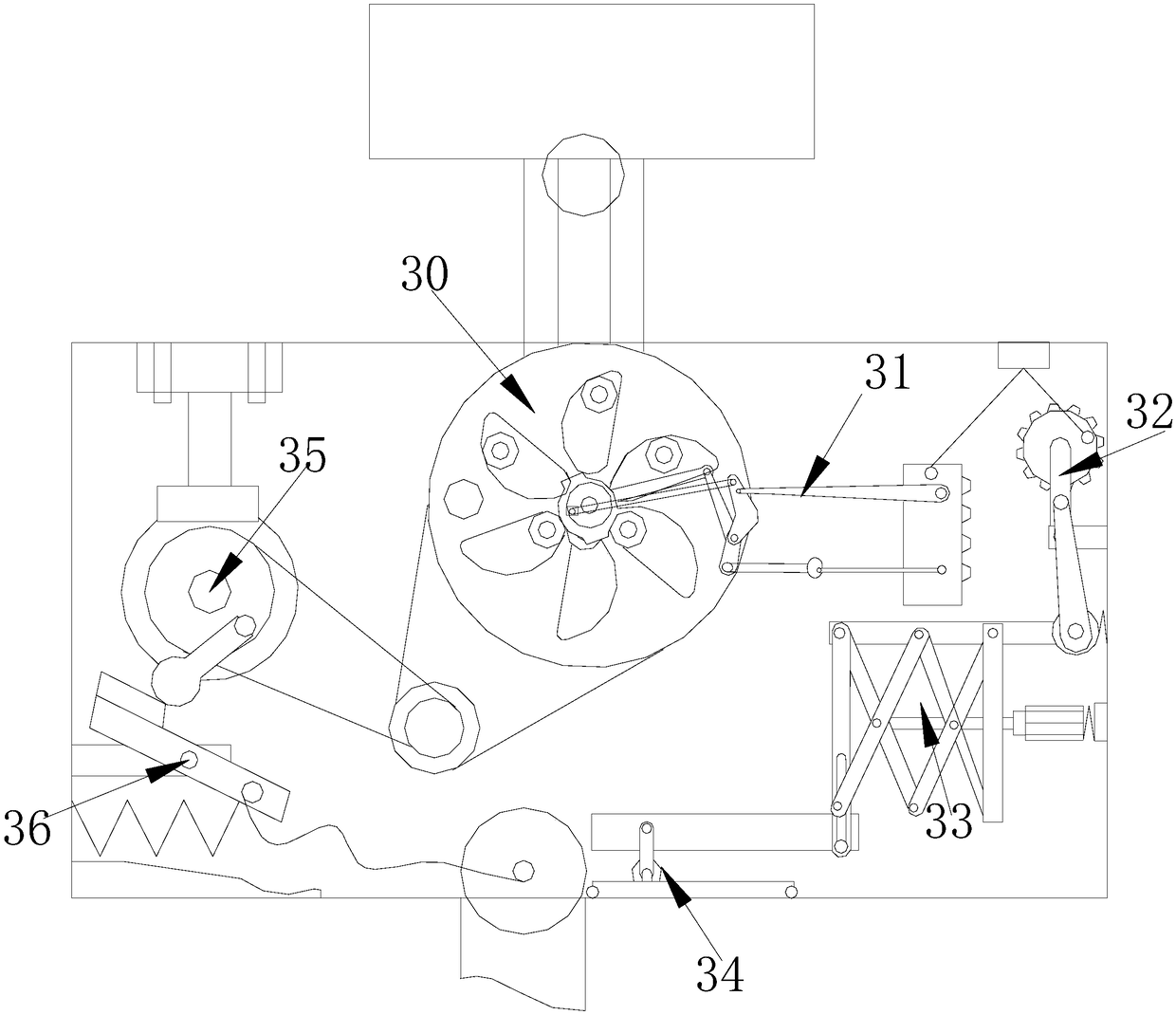

[0028]The compacting device 3 includes a rotating mechanism 30, a pushing device 31, a swinging device 32, a pushing device 33, an opening and closing device 34, a transmission mechanism 35, and a compacting device 36. The rotating mechanism 30 is connected to the powder feeding head 2 by pushing It is also arranged in the middle of the compacting device 3, the pushing device 31 is rotationally co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com