Preparation method and application for polymer-based piezoelectric bimorph

An electric twin, polymer technology, applied in the manufacture/assembly, coating and other directions of piezoelectric/electrostrictive devices to achieve the effect of improving piezoelectric performance, enhancing deformation, and enhancing the ability to drive deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

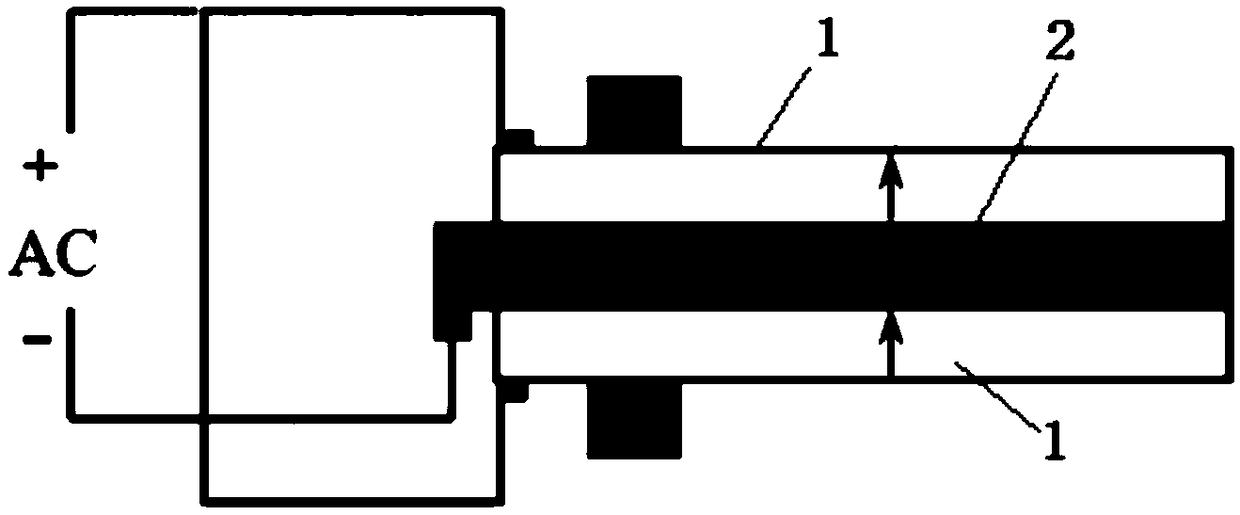

[0015] Embodiment 1: This embodiment is a method for preparing a polymer-based piezoelectric bimorph, which is specifically completed in the following steps:

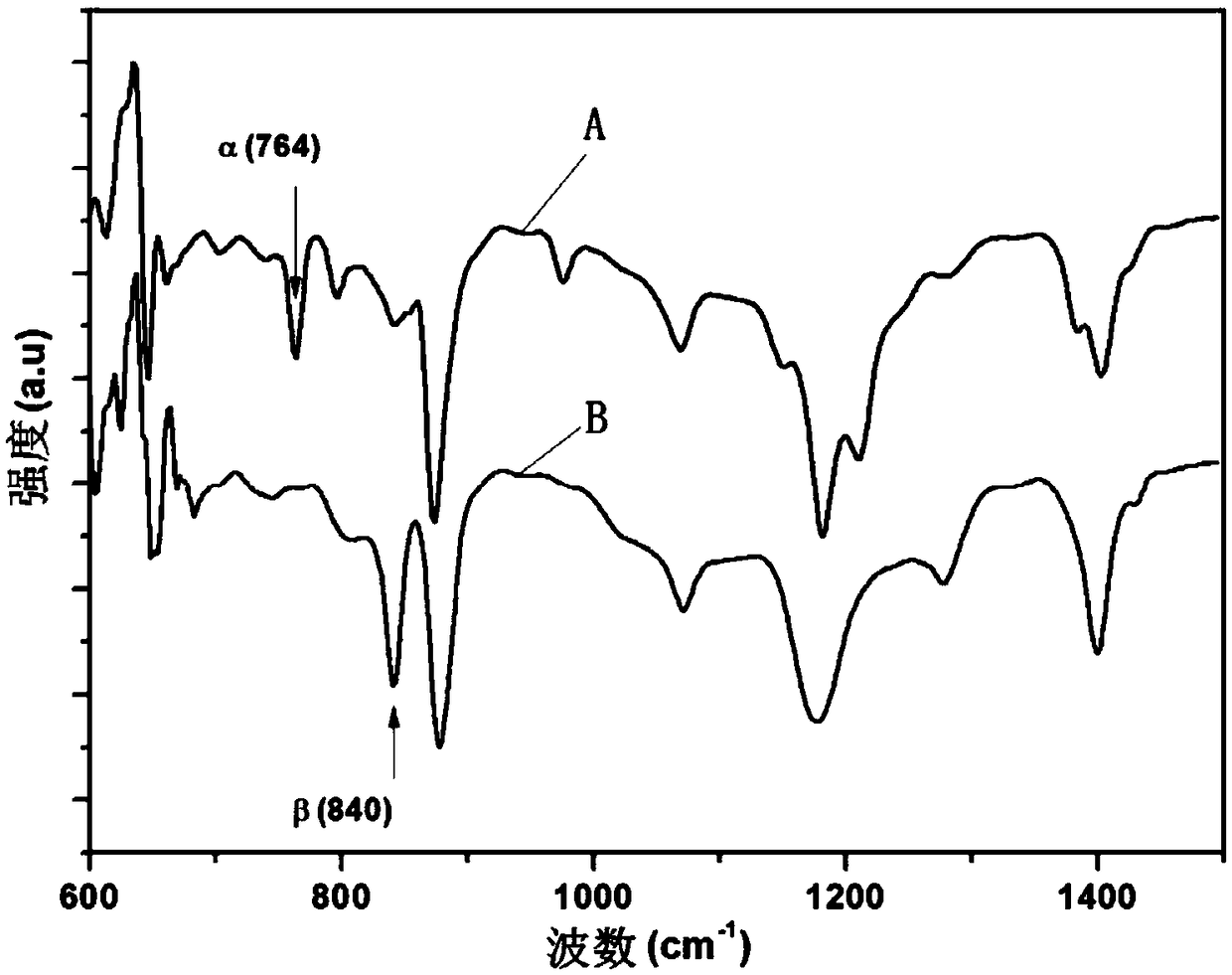

[0016] 1. Preparation of non-polarized PVDF film: ①. Dissolve polyvinylidene fluoride in an organic solvent to prepare a mixed solution. The mass fraction of polyvinylidene fluoride in the mixed solution is 15% to 25%; ②. The solution was stirred, left still and ultrasonically degassed sequentially under the condition of avoiding light and room temperature; ③, repeat step 1 and ② for 2 to 4 times to obtain a uniform solution; ④, put the uniform solution into a vacuum mixer, Stir at room temperature in the dark for 1h to 1.5h to obtain the solution for eliminating air bubbles; ⑤. Ultrasonic debubble the solution for 8 minutes to 12 minutes, and then stir for 8 minutes to 12 minutes; In the petri dish, let it stand for 8 minutes to 12 minutes, and then put it in a constant temperature drying oven to dry, that is, the PVDF...

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one (2), the mixed solution is first stirred at a stirring speed of 400 ~ 500r / min for 30min under the condition of avoiding light and room temperature, and then left standstill 10 minutes, and finally ultrasonic defoaming treatment was performed at an ultrasonic power of 100W for 5 minutes to 8 minutes. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1 ⑥, dry at a constant temperature of 60-70°C for 1 hour, then raise the temperature to 140°C, and keep the temperature at 140°C Dry for 2h. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com