Thermal conductivity meter for vacuum glass

A technology of vacuum glass and thermal conductivity meter, which is applied in the field of measuring instruments, can solve the problems of small thermal conductivity of vacuum glass, large error, and difficulty in finding insulation boards, etc., achieve good thermal insulation performance, and eliminate measurement errors and system errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

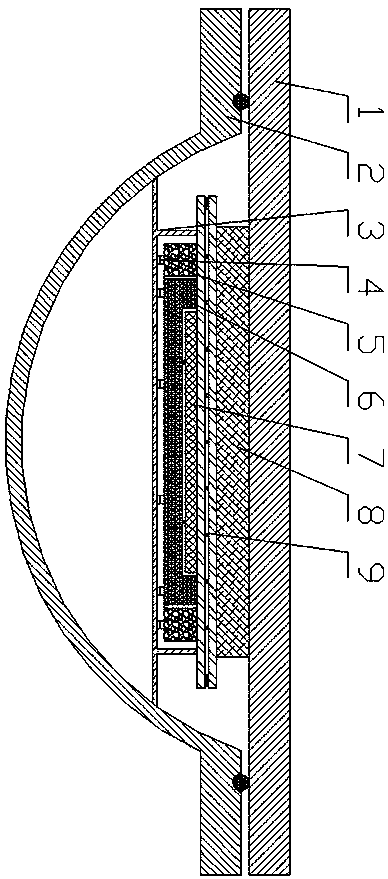

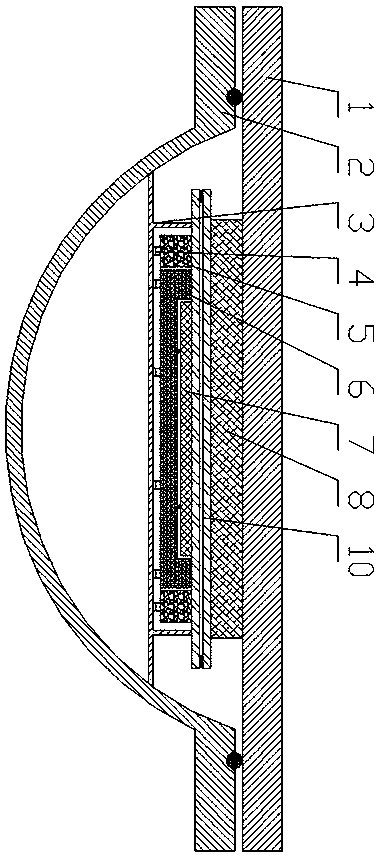

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] like figure 1 and figure 2 An embodiment of the present invention is shown. A vacuum glass thermal conductivity meter is composed of an upper shell 1 and a lower shell 2. After the upper shell 1 and the lower shell 2 are closed, they are sealed by a rubber sealing ring, and the inside is sealed by a vacuum. The system forms a high vacuum; the hot plate is composed of a protective hot plate 5, a buffer hot plate 6 and a measuring hot plate 7, which are installed in the chassis 3 through the heat insulating support 4, and the heat insulating support 4 is elastic, so that the hot plate can be in close contact with the vacuum glass; The inner surface of the chassis 3 is a low-emissivity surface (aluminum, silver or gold, or aluminum foil, etc.), which can insulate radiant heat, and the chassis 3 is installed in the lower shell 2 for heat insulation; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com