Oil-water mixed combustion device of internal combustion engine

A technology of oil-water mixing and combustion devices, which is applied to internal combustion piston engines, combustion engines, and adding non-fuel substances to fuel, etc., can solve the problems of reducing engine energy efficiency, inability to achieve complete combustion, and energy loss, etc., to achieve clean emissions and promote secondary Secondary combustion phenomenon, high energy efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

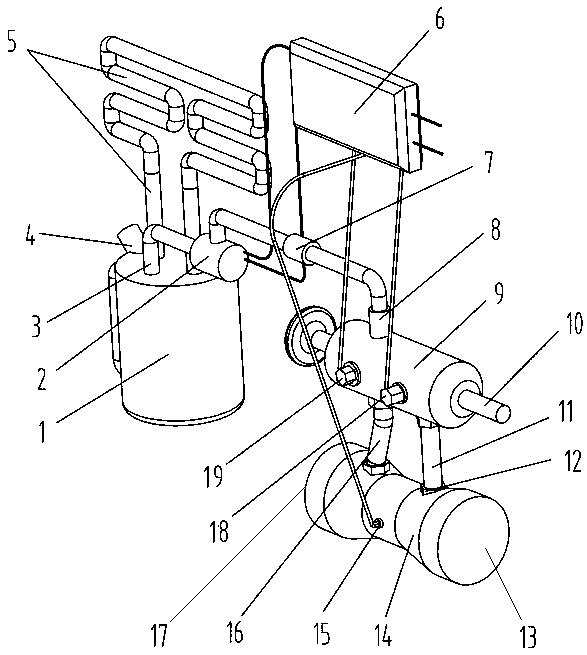

[0009] An oil-water mixed combustion device for an internal combustion engine, comprising a preheating water tank 1, a steam generator 9, and a Venturi tube 14. It is equipped with a water inlet 4 for replenishing the water source in time and a water level gauge for observing the water storage; the preheated water tank 1 is connected with the steam generator 9 through the water suction pipe 3, and one end of the water suction pipe 3 is inserted into the preheated water tank 1, and the other end is passed through The one-way valve 8 is connected to the steam generator 9, and the water suction pipe 3 is equipped with a metering pump 2 and a solenoid valve 7; the steam generator 9 is a sealed body, which is welded to the front section of the exhaust pipe 10 of the internal combustion engine (away from the gas outlet end), and the steam generates A water level sensor 18 and a temperature sensor 19 are installed on the device 9. The air inlet of the steam generator 9 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com