Anti-coking structure of double furnace heat transfer oil boiler

A heat-conducting oil boiler and anti-coking technology, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as coking, low heating efficiency, and unreasonable structure, so as to improve heat exchange effect and simplify Structure, effect of improving heating efficiency and heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

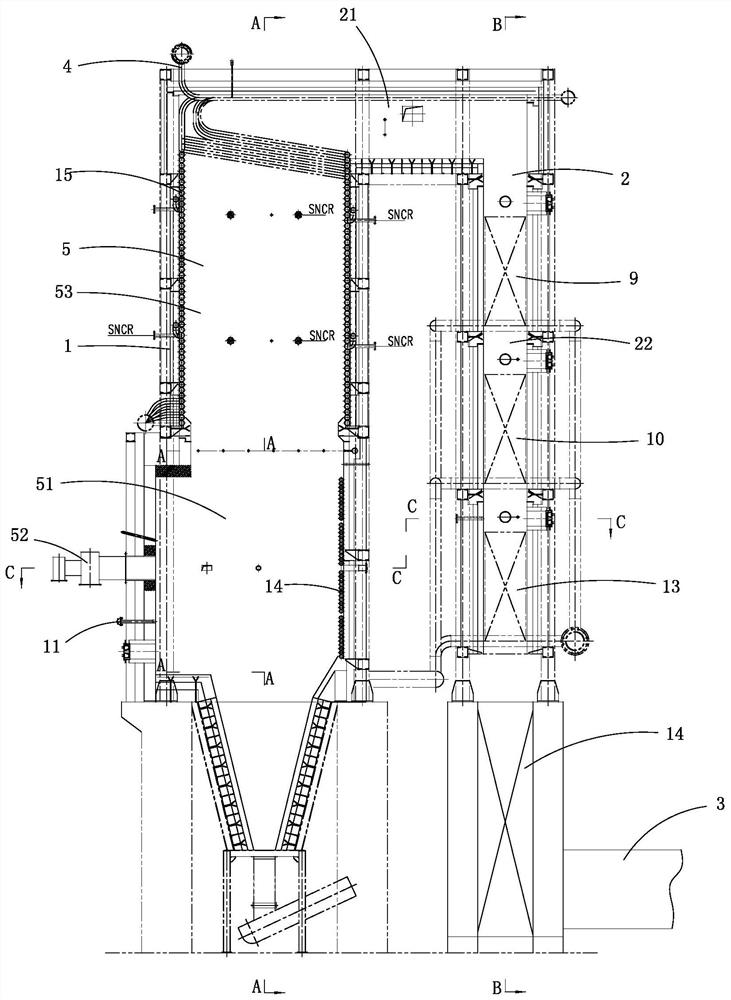

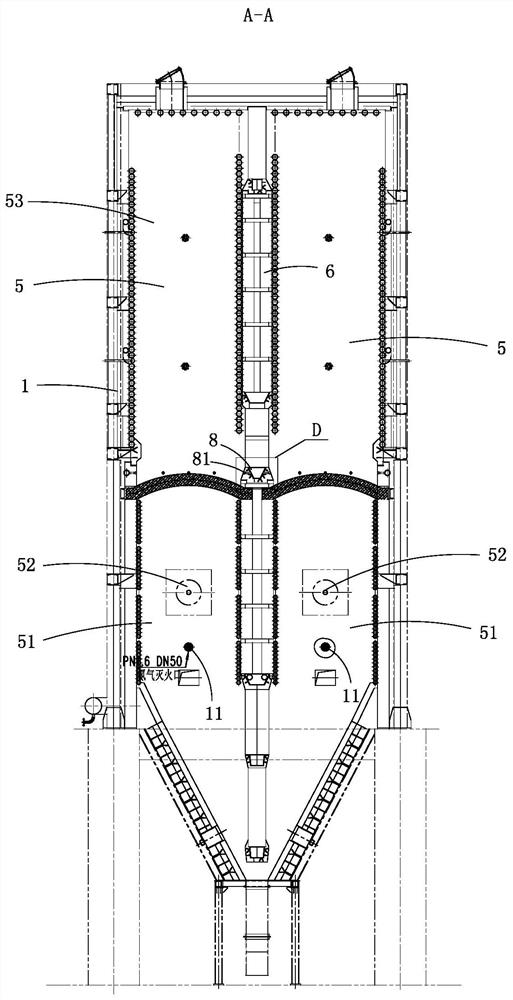

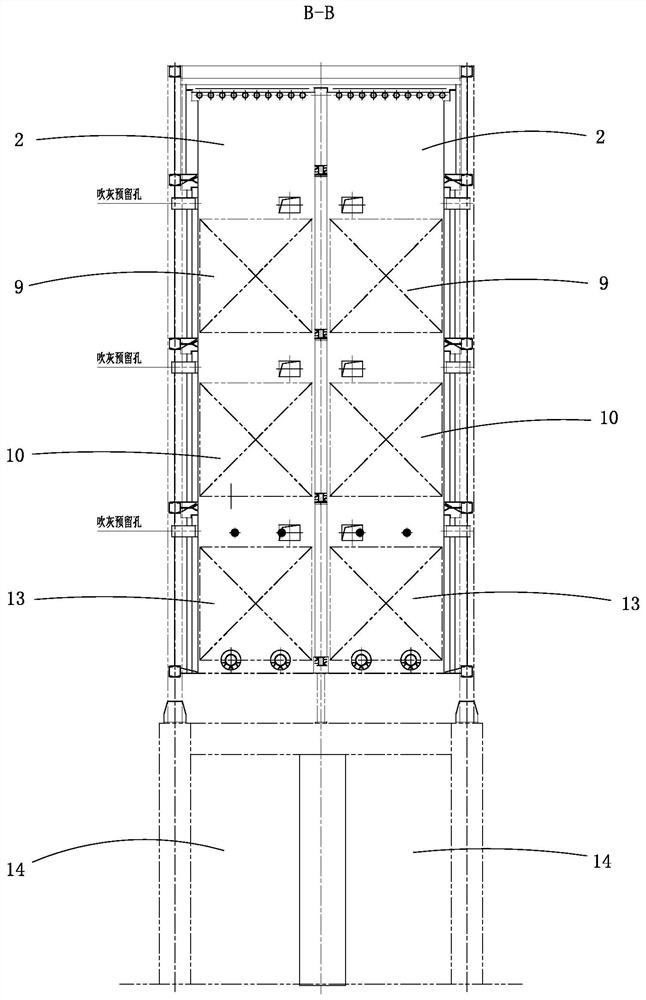

[0021] The specific structure of the present invention is described below in conjunction with the accompanying drawings:

[0022] An anti-coking structure of a double-chamber heat-conducting oil boiler, such as Figure 1 to Figure 7 As shown, it includes a furnace body 1, a flue 2 and a heat conduction oil pipe 4; the inside of the furnace body 1 is divided into two furnace chambers 5 by a partition wall 6, the number of the flue 2 is two, and the two flue 2 They are respectively connected with the smoke outlets at the tops of the two furnaces 5; the bottoms of the two furnaces 5 are provided with combustion chambers 51, and the sides of the combustion chambers 51 are provided with pulverized coal burners 52, and the inner walls of the combustion chambers 51 are U-shaped horizontal coil pipes 14 are closely arranged on the top, and the pulverized coal burners 52 are arranged opposite to the corresponding U-shaped horizontal coil pipes 14, as Figure 8 As shown, the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com