Device for the combustion of organic substances

一种有机物、设备的技术,应用在用于燃烧有机物的设备领域,能够解决废气余热未被利用等问题,达到穿流率改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

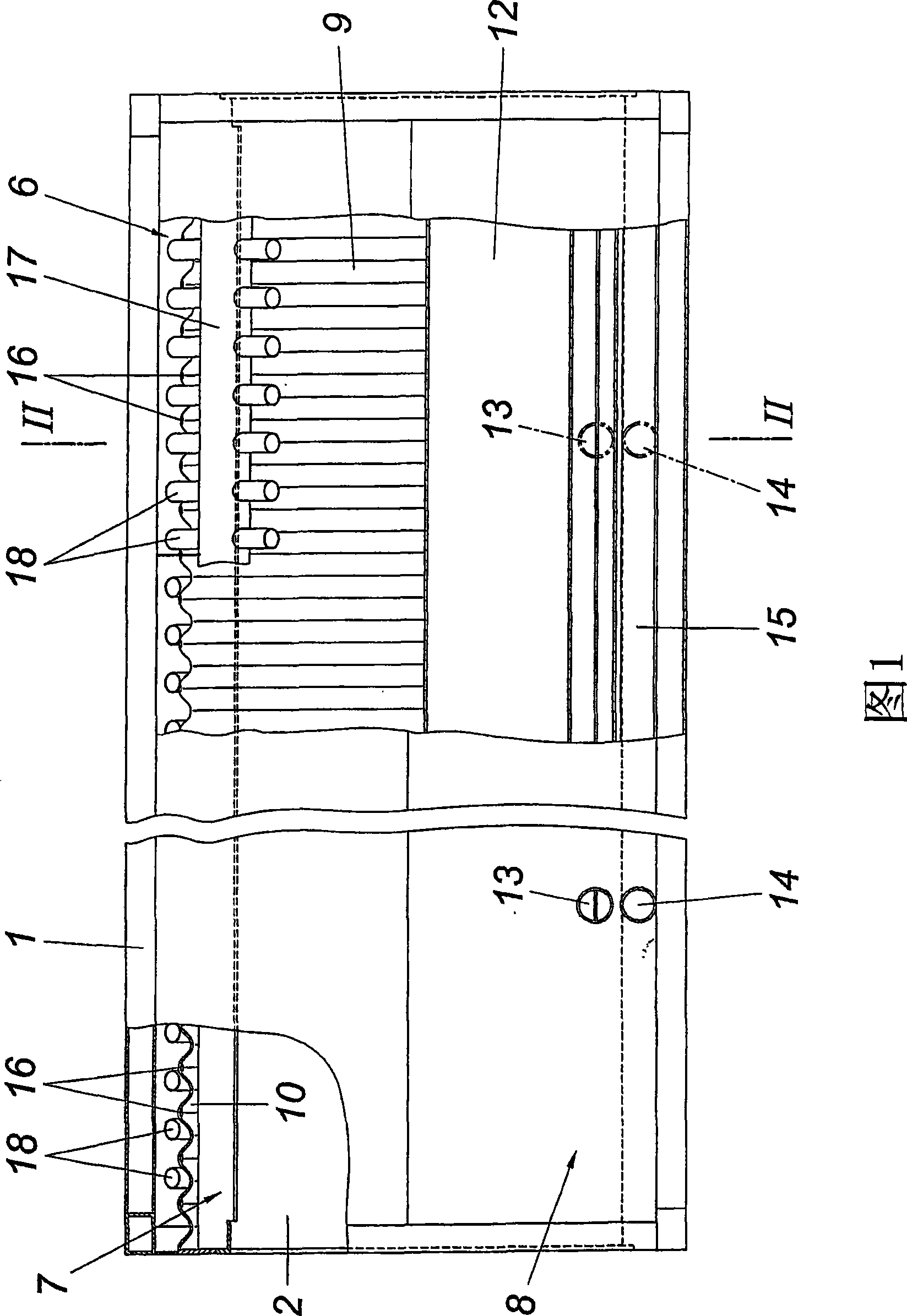

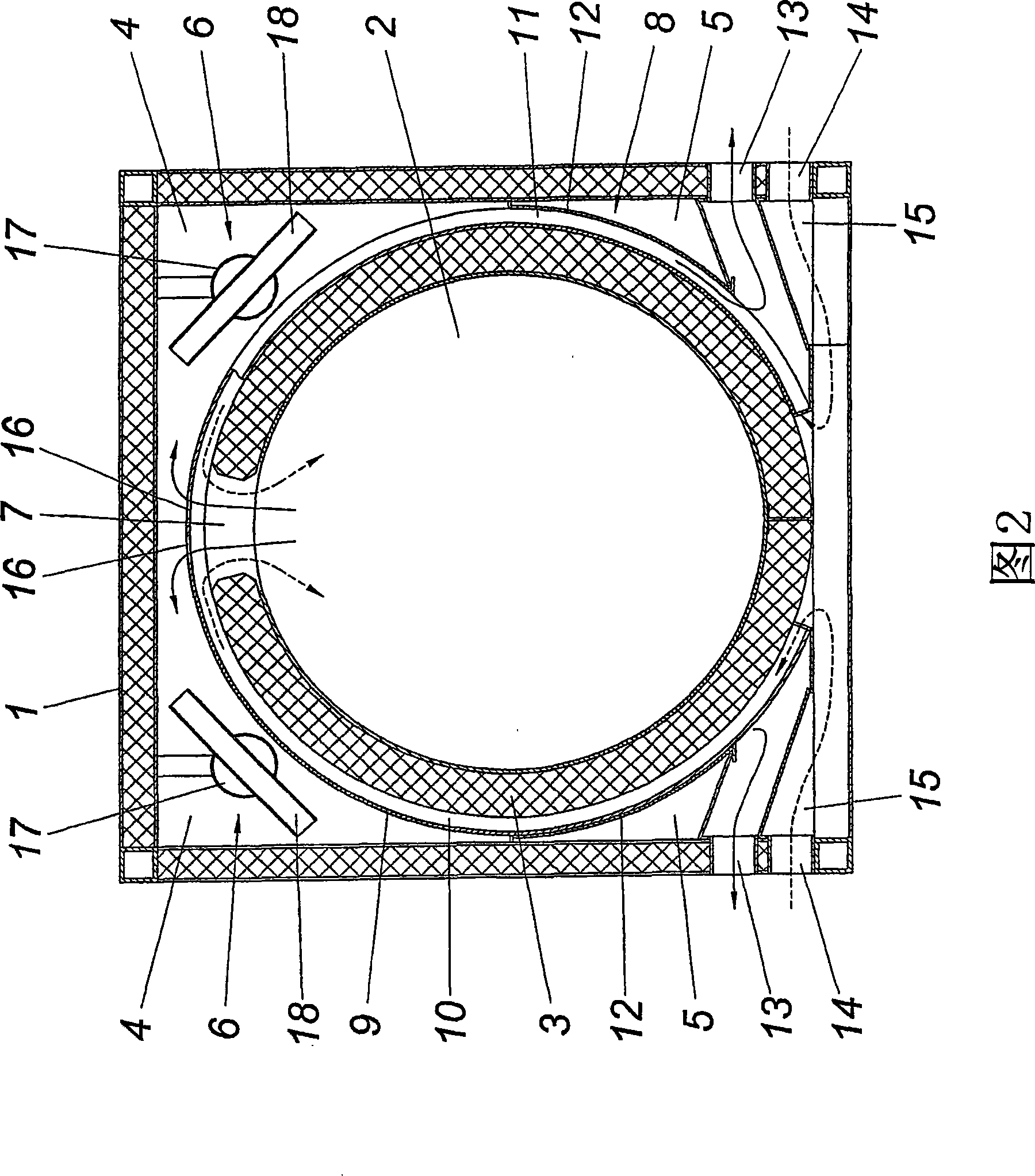

[0011] The device for burning organic matter, especially waste, has a prismatic housing 1 with a substantially cylindrical combustion chamber 2 with a square cross-section and a combustion chamber with a transverse axis. The combustion chamber is provided with thermal insulation means 3 shielding the combustion chamber with respect to the casing 1 . According to the arrangement of the substantially cylindrical combustion chamber 2 in the prismatic housing 1 with a square cross section, wedge-shaped cavities 4, 5 are obtained in the corner regions of the housing 1 between the combustion chamber 2 and the housing 1, in which The wedge-shaped cavity 4 on both sides of the upper part of the combustion chamber 3 accommodates a heat exchanger 6 for the heat carrier running parallel to the combustion chamber 2 .

[0012] The hot exhaust gases exit the combustion chamber 2 through exhaust gas outlet openings 7 arranged in the top region of the combustion chamber 2 and extend substanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com