Cleaning treatment method of glycine production wastewater

A technology for clean treatment and production of wastewater, applied in multi-stage water treatment, natural water treatment, water treatment parameter control, etc., can solve yield and quality fluctuations, poor process stability, increased pressure of condensed water reuse, etc. problems, to achieve the effect of simple equipment, guarantee of green production, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

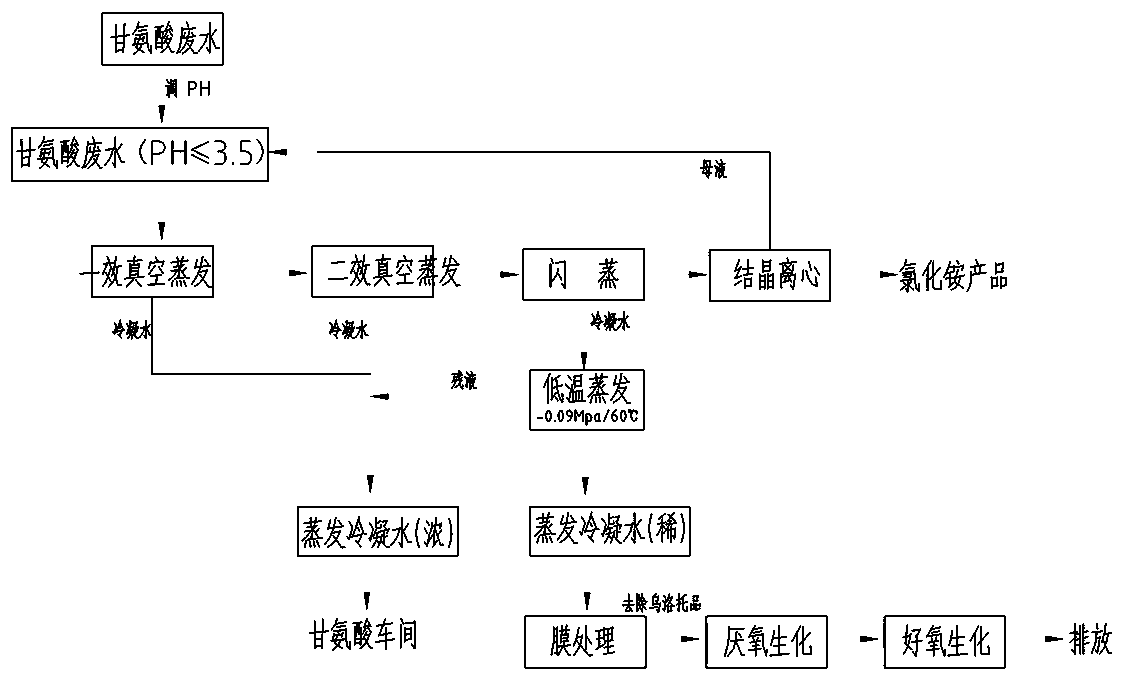

Method used

Image

Examples

Embodiment 1

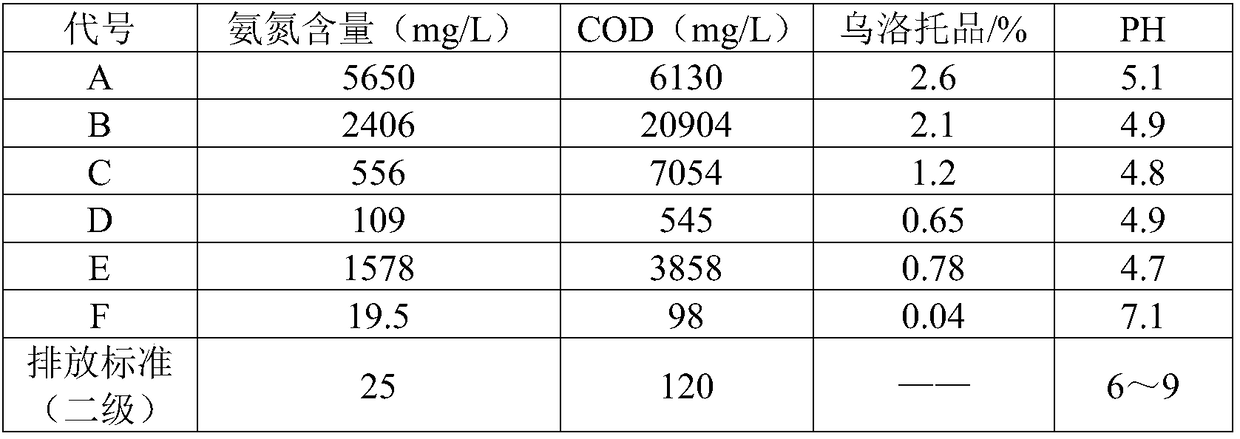

[0026] Use 31% hydrochloric acid to adjust glycine waste water to pH = 3.5 at 100m 3 The mother liquor is continuously poured into the first-effect evaporation system (vacuum degree -0.03Mpa, temperature 110°C) for concentration, and the first-effect evaporation condensate (A) is about 32.22 m 3 . The first-effect concentrated liquid is poured into the second-effect evaporation system (vacuum degree -0.07Mpa, temperature 85°C) for concentration, and the second-effect evaporation condensate (B) is about 25.06m 3 . The two-effect concentrated liquid is poured into the decompression flash system (vacuum degree -0.08Mpa) for concentration, and the flash condensate (C) is about 14.32m 3 . The final concentrate was crystallized and centrifuged to obtain 38.7 tons of ammonium chloride. will be 14.32m 3 The flash condensed water is poured into the low-temperature evaporation system (vacuum degree -0.09Mpa, temperature 70°C) to continue to concentrate, producing dilute waste liqui...

Embodiment 2

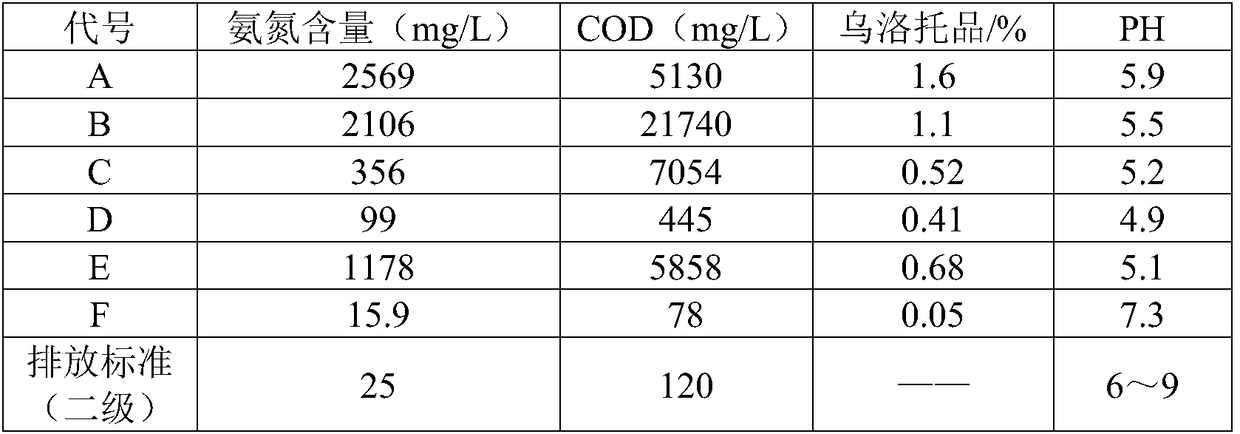

[0029] Use 31% hydrochloric acid to adjust glycine wastewater to pH=2 at 100m 3 The mother liquor is continuously poured into the first-effect evaporation system (vacuum degree -0.03Mpa, temperature 110°C) for concentration, and the first-effect evaporation condensate (A) is about 30.78 m 3 . The first-effect concentrated liquid is poured into the second-effect evaporation system (vacuum degree -0.07Mpa, temperature 85°C) for concentration, and the second-effect evaporation condensate (B) is about 24.76m 3 . The two-effect concentrated liquid is poured into the decompression flash system (vacuum degree -0.08Mpa) for concentration, and the flash condensate (C) is about 15.12m 3 . The final concentrate was crystallized and centrifuged to obtain 38.7 tons of ammonium chloride. will be 15.12m 3 The flash condensed water is poured into the low-temperature evaporation system (vacuum degree -0.09Mpa, temperature 60°C) to continue to concentrate, producing dilute waste liquid (D)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com