Tool abrasion visual examination device and method for numerical control turning machining

A tool wear and turning technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reduced efficiency, easy to produce misjudgment, single judgment conditions, etc., to reduce detection time, improve work efficiency, Simple and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

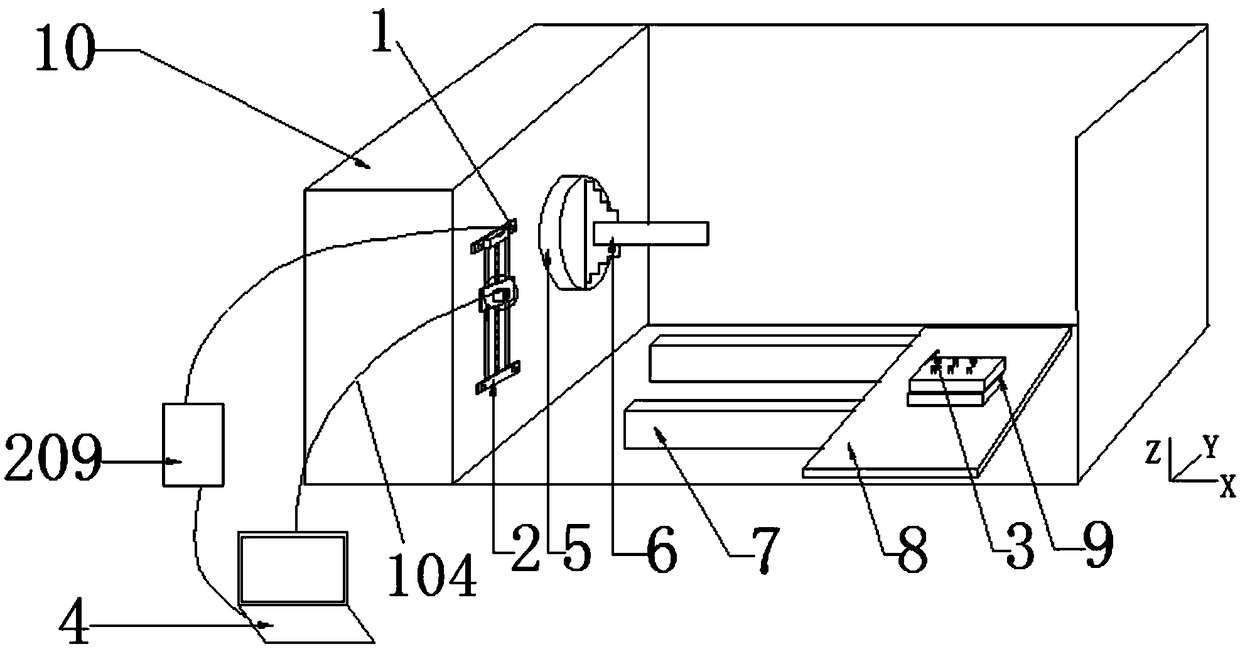

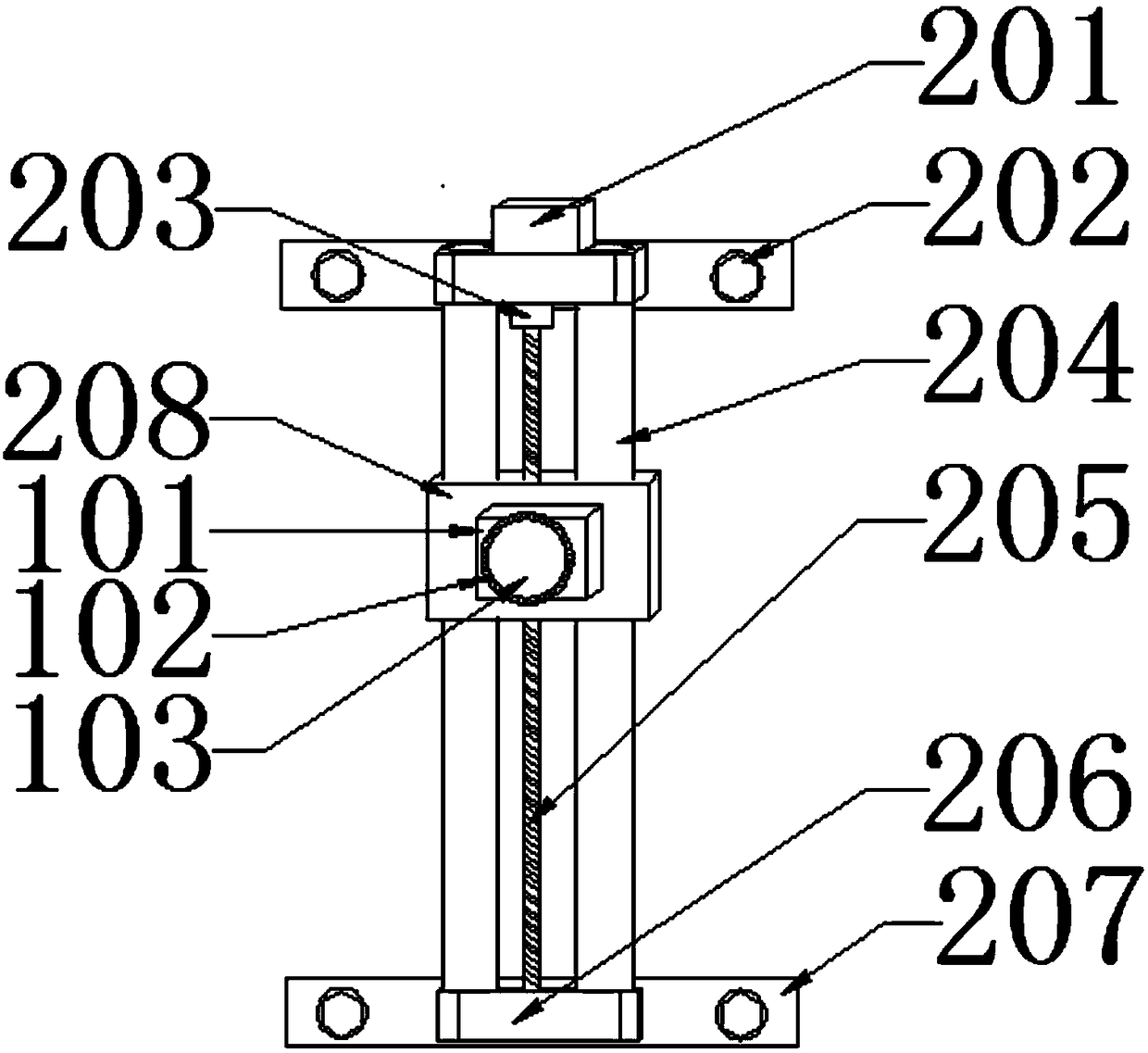

[0027] The invention provides a tool wear inspection device for numerically controlled turning (see Figure 1-2 , referred to as the device), it is characterized in that the device includes an image acquisition device 1, a drive device 2 and a computer 4; the drive device 2 is installed on the headstock 10; the image acquisition device 1 is installed on the drive device 2;

[0028]Described image acquisition device 1 comprises digital CCD camera 101, LED ring light source 102 and telecentric lens 103; Described digital CCD camera 101 is connected by screw thread with telecentric lens 103; The Ethernet line 104 is connected with the computer 4; the LED ring light source 102 is fixedly connected with the telecentric lens 103 by screws to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com