Energy-saving white smoke plume removal device applicable to small and medium-sized boilers

An energy-saving, small and medium-sized technology, applied in the field of flue gas purification, can solve the problems of high operation and maintenance cost, easy corrosion and blockage of equipment, large equipment investment, etc., and achieve the effect of convenient operation and maintenance, less installation work, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

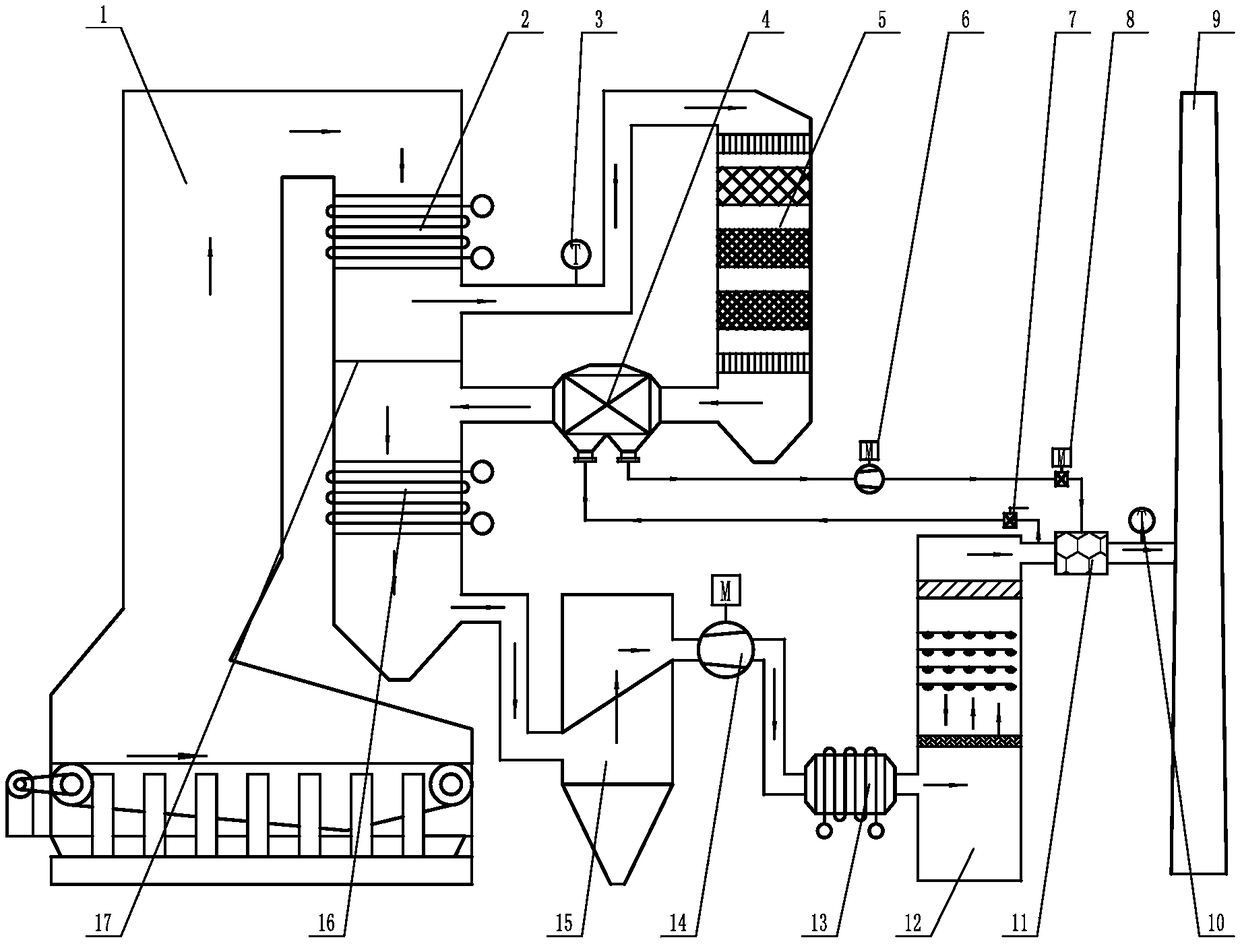

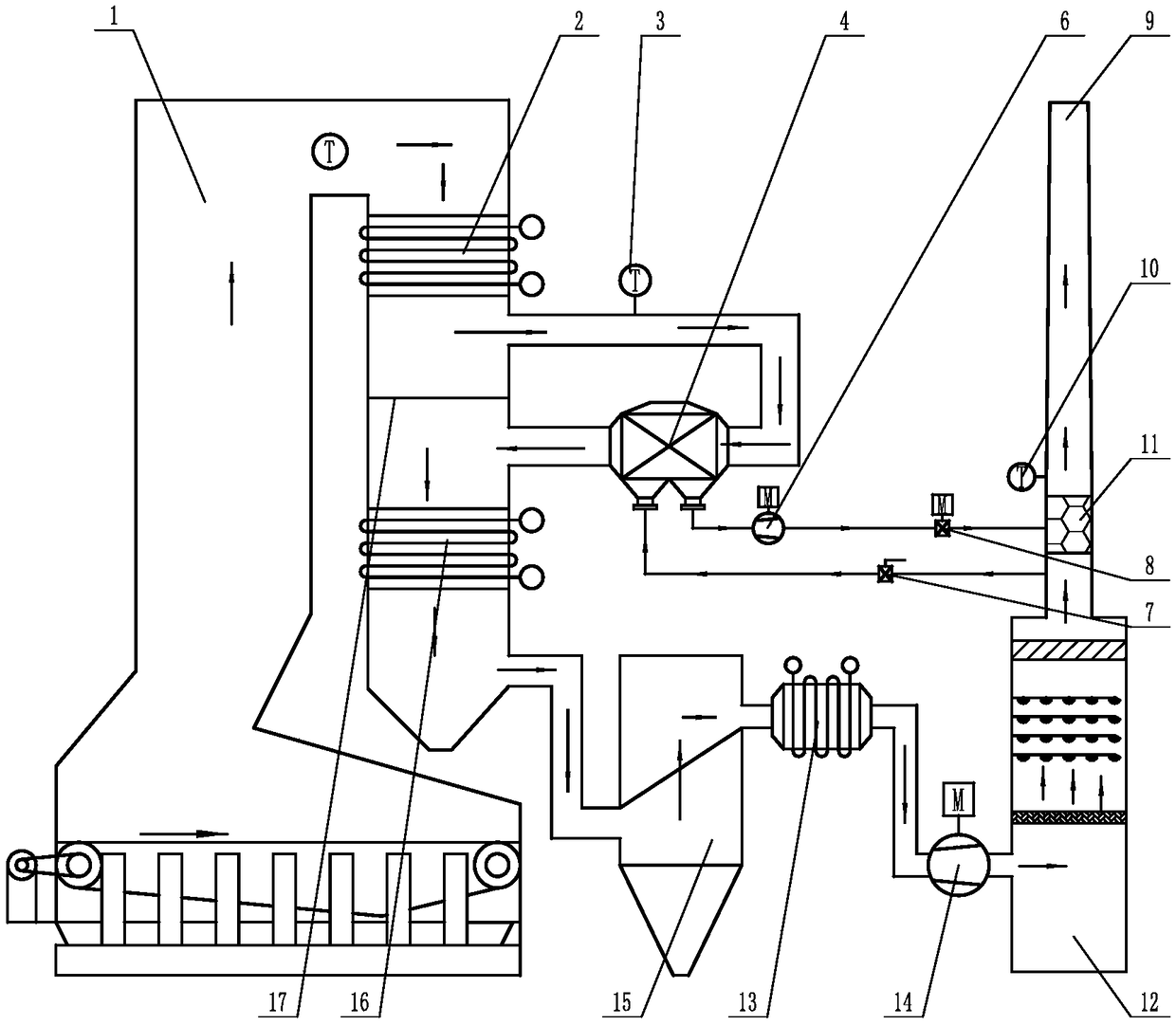

[0025] Specific implementation mode one: as figure 1 and image 3 As shown, the energy-saving flue gas dewhitening device suitable for small and medium-sized boilers in this embodiment includes a temperature transmitter 3, a heat exchanger 4, an SCR reactor 5, an ultra-low temperature economizer 13, a hot flue gas fan 6, a cooling Flue gas valve 7, hot flue gas electric valve 8, temperature controller 10 and mixer 11, a flue partition 17 is arranged between the first economizer 2 and the second economizer 16, the SCR reactor 5 and the boiler The outlet of the upper flue of 1 is connected, the temperature transmitter 3 is set on the pipeline between the SCR reactor 5 and the boiler 1, the outlet of the SCR reactor 5 is connected with the inlet of the lower flue of the boiler 1 through the heat exchanger 4, and the mixing The device 11 is set at the outlet of the ultra-clean desulfurization equipment 12 and the two are connected to each other. The lower end of the heat exchange...

specific Embodiment approach 2

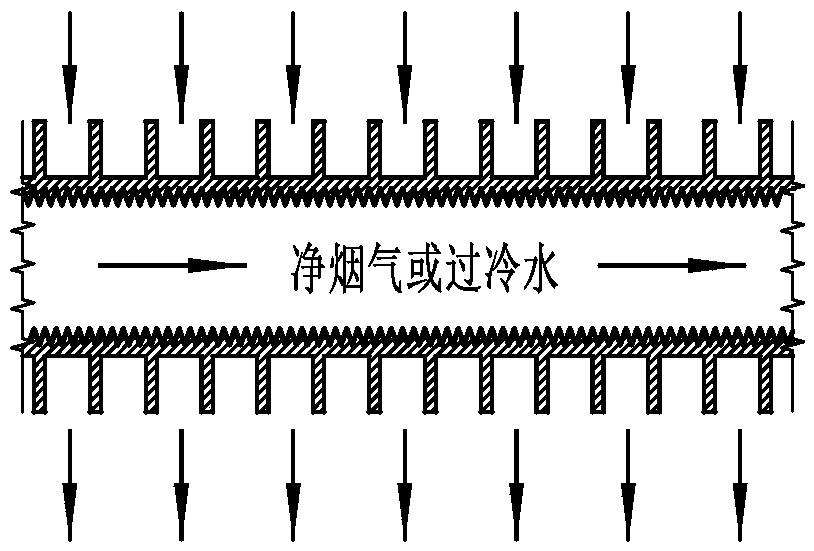

[0031] Specific implementation mode two: as image 3 As shown, the heat exchanger 4 in this embodiment is a tube heat exchanger. With such a design, the high-temperature flue gas flows outside the heat exchange tube, and the clean flue gas flows in the heat exchange tube. The high-temperature flue gas and the clean flue gas are mixed and arranged. The gas section is downstream. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: as figure 1 and image 3 As shown, the inner wall of the heat exchange tube of the heat exchanger 4 in this embodiment is processed with internal threads, and the outer wall of the heat exchange tube of the heat exchanger 4 is uniformly provided with fins along its length direction. This design greatly increases the heat exchange area and reduces the material consumption of the heat exchanger. The external high-temperature flue gas contains smoke and dust, and the anti-clogging and anti-wear fins are used to increase the heat exchange area. The internal flue gas is clean and dust-free. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com