Solar cell module and preparation method thereof

A solar cell and module technology, applied in the field of solar cells, can solve problems such as lead-out of solder ribbons, inability to fully utilize the module area, and increase the risk of debris, so as to reduce the rate of debris, increase efficiency and installation costs, and enhance the ability to resist hot spots Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

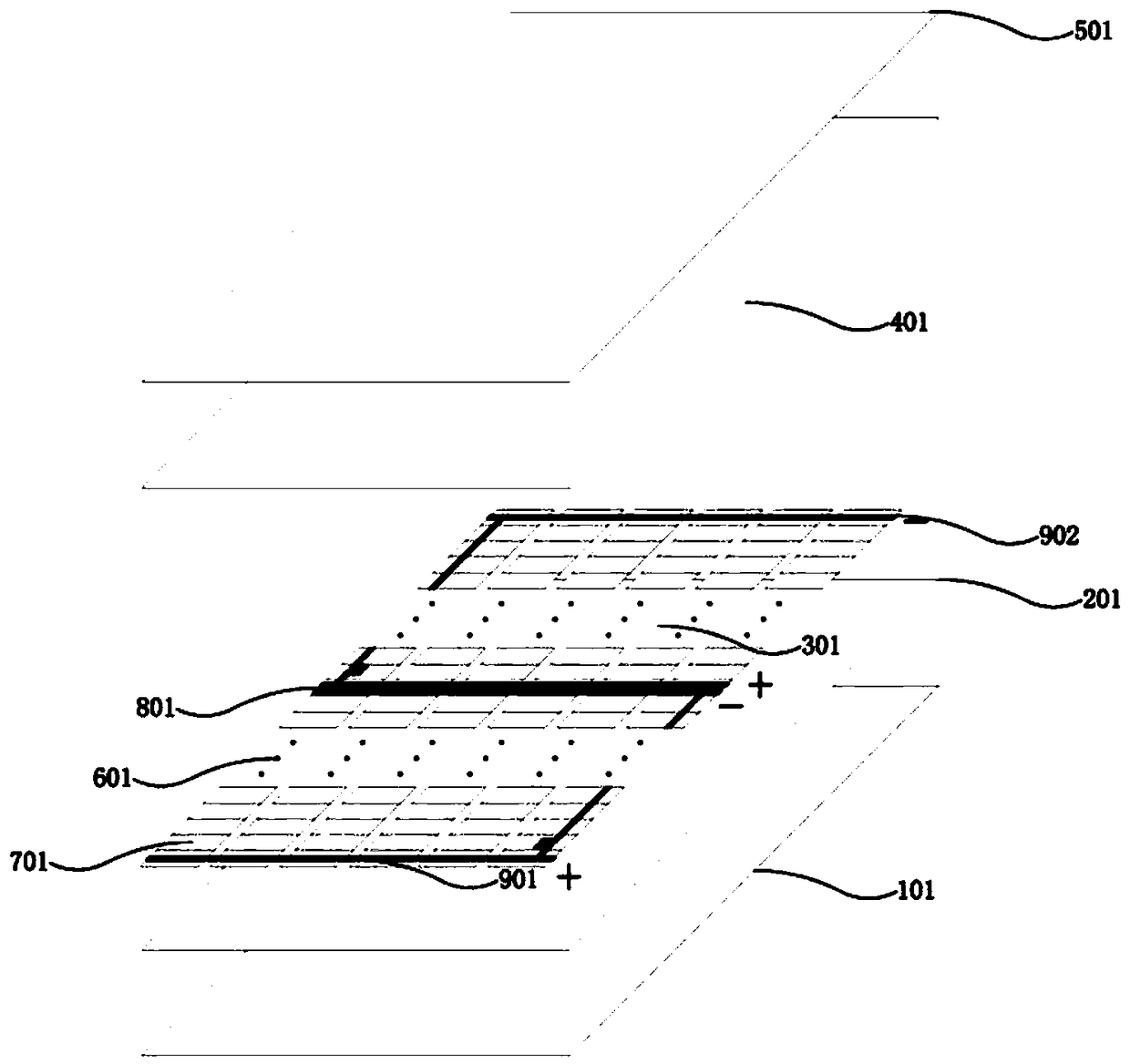

[0075] figure 1 It is a schematic structural view of the solar cell module in Embodiment 1 of the present invention, as figure 1 As shown, the shingled solar cell module provided in this embodiment includes a cover material 101, a first encapsulant film 201, battery strings 301, a second encapsulant film 401, and a back sheet material 501 in sequence from bottom to top. , the battery string group 301 is formed by connecting multiple battery strings 601, and each battery string 601 is formed by connecting multiple first-type battery slices 701 and at least one second-type battery slice 801, wherein multiple first-type battery slices The polarities of the front electrodes of 701 are consistent, and the polarities of the back electrodes of the plurality of first-type battery sheets 701 are also consistent, and the front electrodes of the plurality of first-type battery sheets 701 and the polarities of the plurality of first-type battery sheets 701 The polarity of the electrodes ...

Embodiment 2

[0108] The structure of the solar cell module provided in this embodiment is the same as that in Embodiment 1.

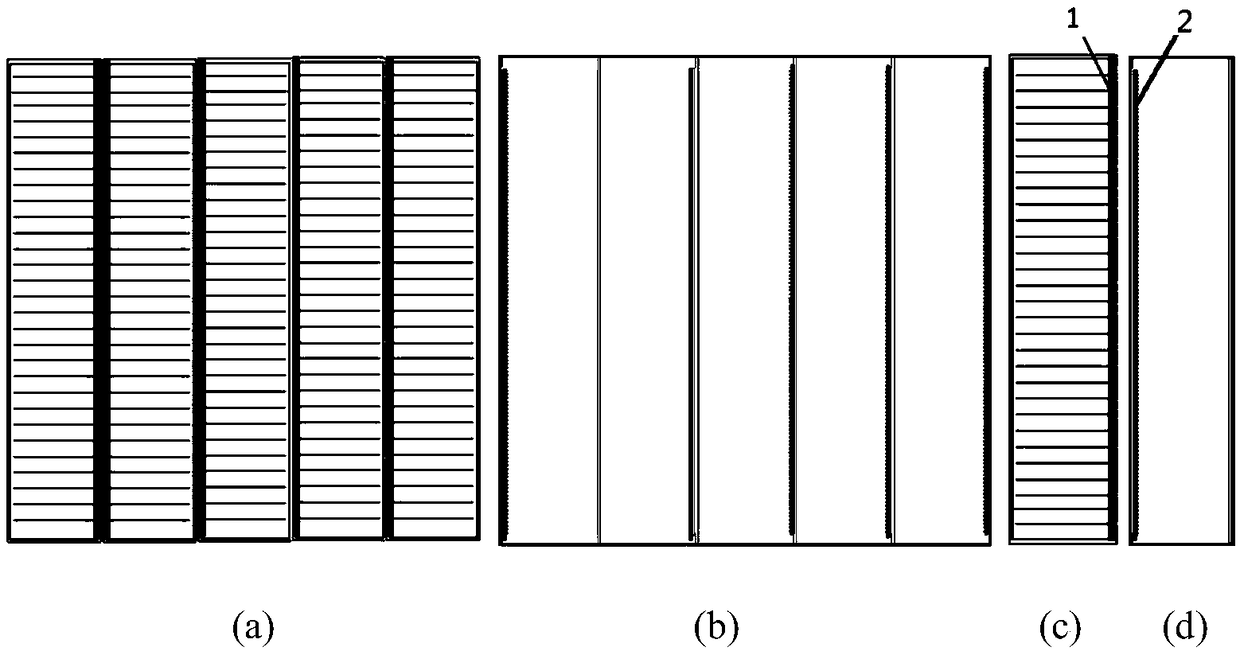

[0109] The first battery sheet is a conventional battery sheet, and the conventional battery is the same as in Example 1, such as figure 2 and image 3 As shown, the front and back sides of the first type of solar cell are respectively provided with main grids, and the whole solar cell before cutting is cut at the reserved position close to the main grid to form multiple first type of solar cells, and the main grids are distributed in On the long side of the first type of battery and perpendicular to the short side of the first type of battery.

[0110] like Figure 8 As shown, the second type of battery sheet is a back contact battery sheet, the front side of the back contact battery sheet is not provided with electrodes, and the positive and negative electrodes of the back contact battery sheet are all arranged on the back side of the back contact battery shee...

Embodiment 3

[0123] The structure of the solar cell module provided in this embodiment is the same as that in Embodiment 1.

[0124] like figure 2 As shown, the front and back of the first battery sheet are respectively provided with busbars, and the first battery sheet is cut near the reserved position of the busbar to form a plurality of first battery sheets, and the busbars are distributed on the first battery sheet. On the long side of the cell and perpendicular to the short side of the first type of cell.

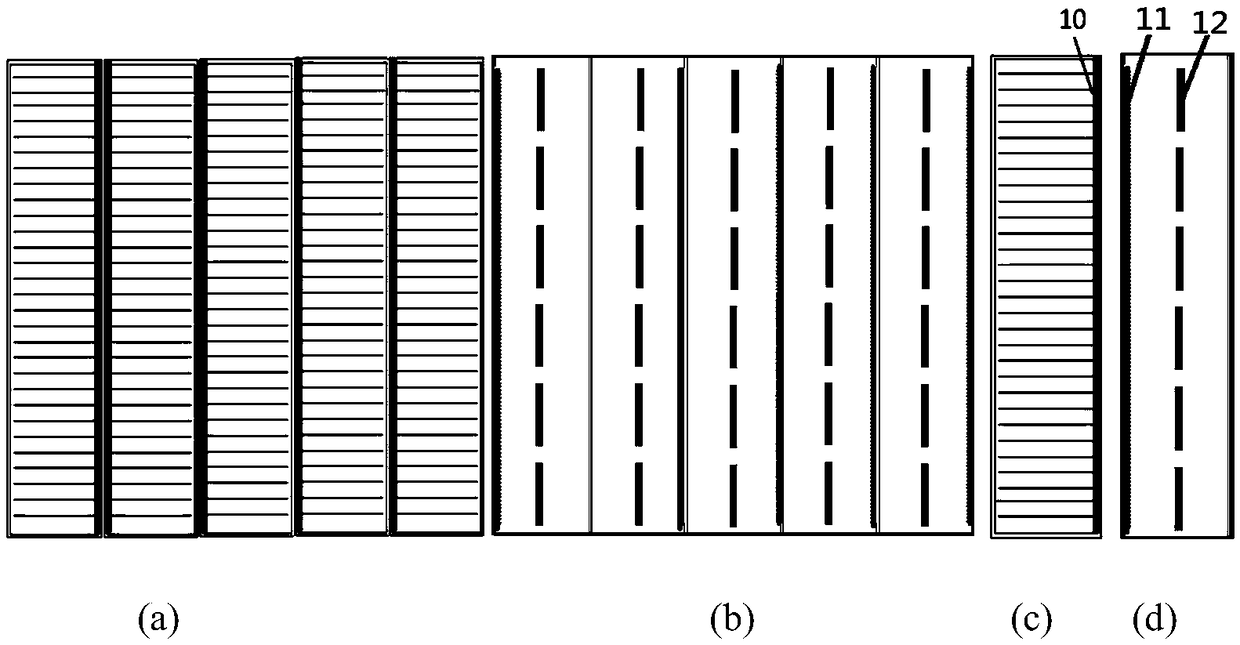

[0125] like Figure 10 As shown, the second type of cell is a back-contact cell. There is no electrode on the front of the back-contact cell, and the positive and negative electrodes of the back-contact cell are both arranged on the back of the back-contact cell. Cutting is performed near the reserved position of the main grid on the back to form a plurality of second battery slices b". The distribution of main grids with the same characteristics, all the main grids are perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com