Oil pretreatment method and oil microwave pretreatment device

A pretreatment device and pretreatment technology, applied in the field of oil and grease processing, can solve the problems of unable to automatically adjust the microwave irradiation intensity, occupy a large area, and consume high energy consumption, achieve fast detection speed, prevent overheating, and save floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

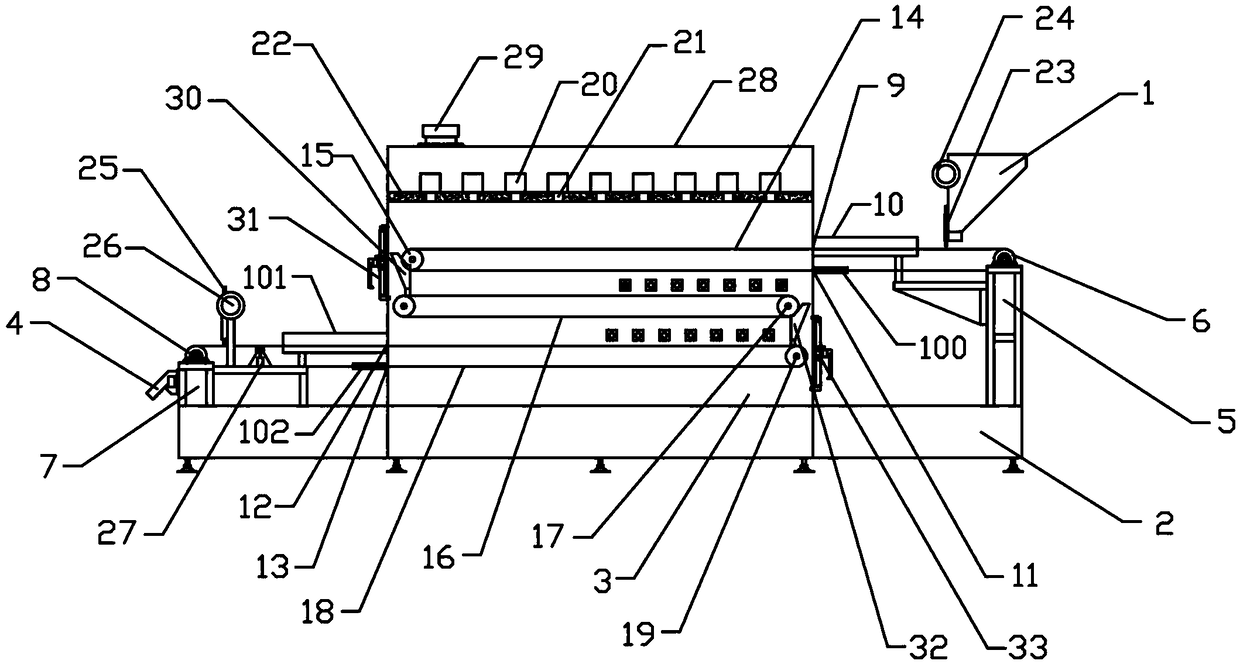

[0028] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0029] A kind of oil plant pretreatment method of the present invention comprises the following steps:

[0030] 1) Clean selection and drying of newly harvested oil seeds: freshly harvested oil seeds are cleaned to remove impurities such as pod shells, soil and stones, and then dried to control their moisture;

[0031] 2) Establish flavor color standard reference: Microwave radiation is carried out on oil seeds after cleaning and drying, and a part of oil seeds with different radiation intensities is firstly removed for seed coat removal and skin kernel separation, and color identification and quantification of kernels are carried out; In the other part, low-temperature pressing is carried out under the same conditions, and sensory evaluation is carried out on the flavor of low-temperature pressed oil whose micronutrient retention rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com