Method for preparing methane by petroleum coke catalytic gasification

A technology of petroleum coke and methane, applied in gasification process, petroleum industry, fixed bed gasification, etc., can solve the problems of difficult recovery, corrosion of gasifier, high price, etc., and achieve cost saving, corrosion reduction, and volatile little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

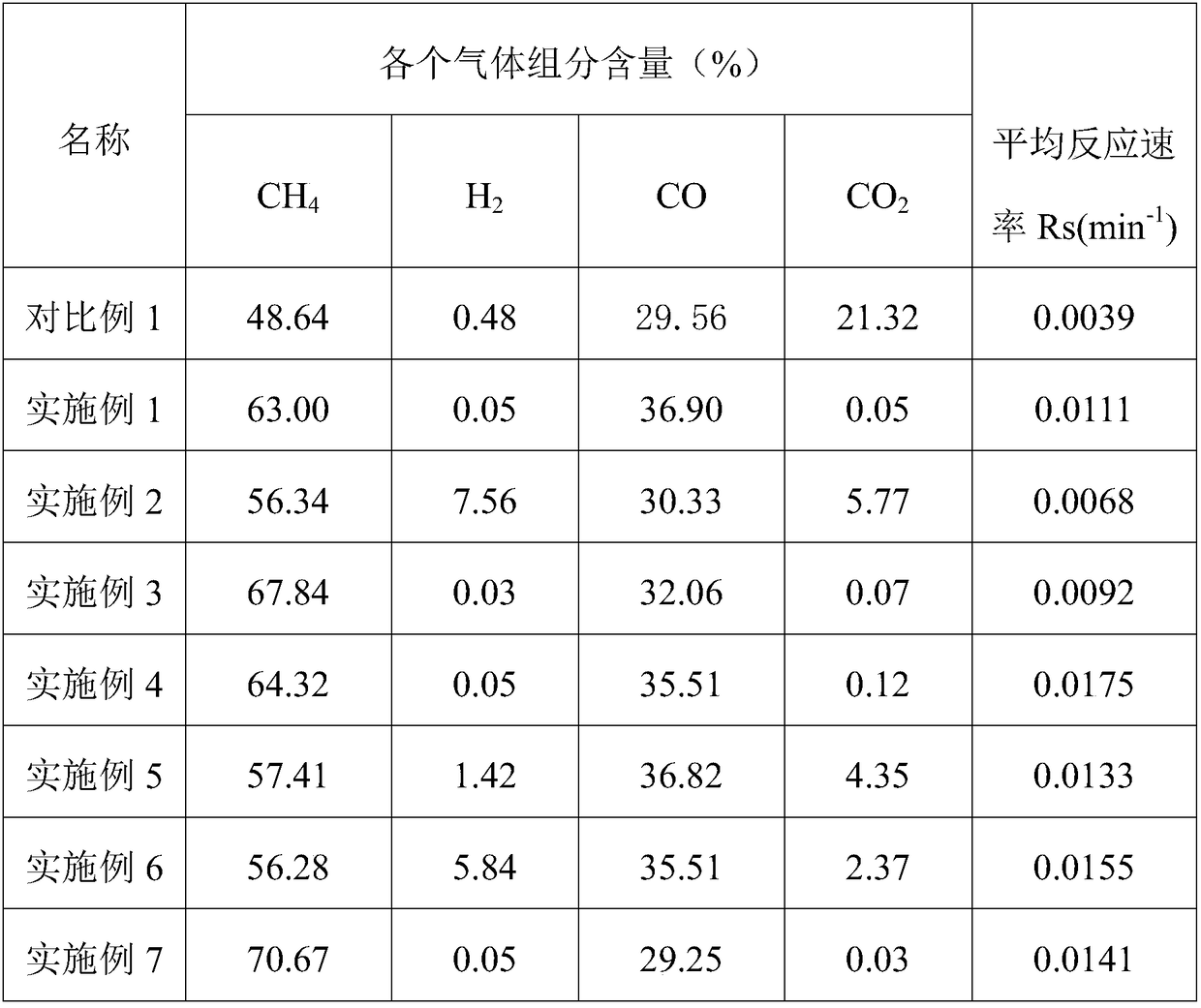

Embodiment 1

[0022] Example 1: Petroleum coke and CaO with a particle size of less than 0.074 mm are respectively introduced into the fluidized bed gasifier, the mass flow rate of petroleum coke is 1 g / min, and the mass flow rate of CaO is 1 g / min. At the same time, at a temperature of 700 ° C, The pressure is 10Mpa, and the water vapor mass flow rate is 1g / min under the working condition of gasification for 120 minutes. The content of each gas component produced is shown in Table 1.

Embodiment 2

[0023] Embodiment 2: In the fluidized bed gasification furnace, feed respectively petroleum coke and ZrO with a particle size less than 0.074mm 2 , the mass flow rate of petroleum coke is 1g / min, ZrO 2 The mass flow rate is 2.14g / min. At the same time, the temperature is 700°C, the pressure is 10Mpa, and the water vapor mass flow rate is 1g / min. Show.

Embodiment 3

[0024] Embodiment 3: In the fluidized bed gasification furnace, feed respectively petroleum coke and ZrO with a particle size less than 0.074mm 2 , the mass flow rate of petroleum coke is 1g / min, Ba 2 TiO 4 The mass flow rate is 5.1g / min. At the same time, the temperature is 700°C, the pressure is 10Mpa, and the water vapor mass flow rate is 1g / min. The gasification is performed for 140 minutes. Show.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com