Method for preparing methane-rich gas through autocatalytic gasification of biomass

A catalytic gasification and biomass technology, which is applied in the manufacture of combustible gas, gas fuel, biofuel, etc., can solve the problems that are not involved, and achieve the effects of easy operation, promotion of generation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

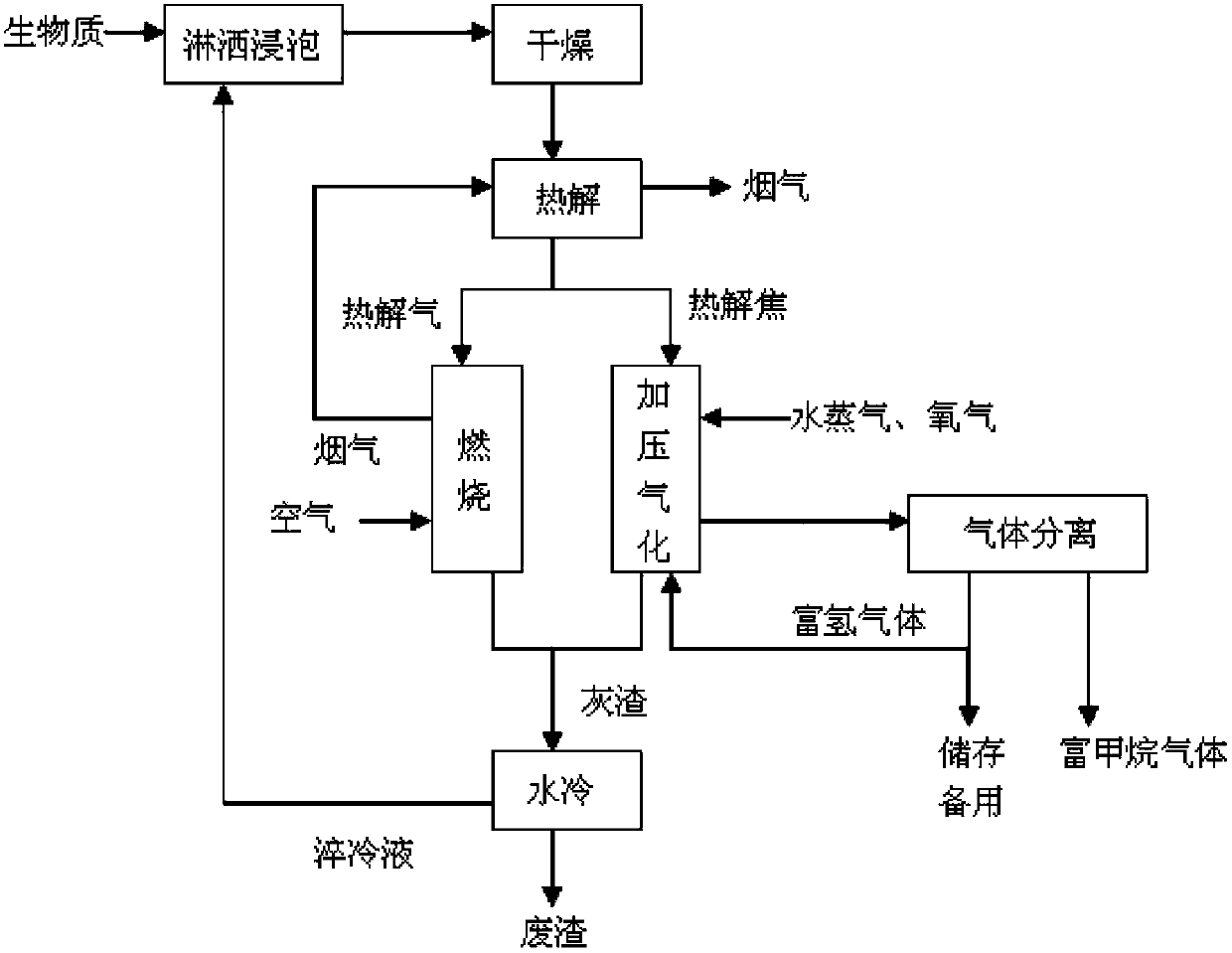

[0036] In this example, a method for producing methane-rich gas by self-catalytic gasification of biomass is used. The technical flow diagram is shown in figure 1 , the process includes the following steps:

[0037] (1) The pine wood powder with an ash content of 1.6% was sprayed and soaked with the quenching liquid of gasification bottom ash and burning ash, and then placed outdoors to dry naturally.

[0038] (2) The air-dried biomass is added to the spiral pyrolysis device for catalytic pyrolysis at 320°C, using flue gas for indirect heating, and the outlet flue gas preheats the air and then is emptied after being treated by the flue gas purification system;

[0039] (3) Send the pyrolysis coke produced by the biomass in the spiral pyrolysis reactor in step (2) into the fluidized bed gasification reactor for pressurized steam / oxygen catalytic gasification, the reaction temperature is about 790°C, The gasification bottom ash is discharged into the ash hopper, the outlet gas ...

Embodiment 2

[0050] The wheat straw powder with an ash content of 10.10% was sprayed and soaked with the quenching solution of gasification bottom ash and combustion ash, the mass ratio of biomass and quenching solution was controlled at 1:0.8, and the potassium, sodium, The total content of calcium and magnesium elements is 3.5%. Then dry to a moisture content of 5.2%. The wheat straw powder is pyrolyzed in a spiral pyrolysis device, using flue gas at 410°C as indirect heat supply, the pyrolysis time is 15 minutes, the average temperature in the spiral reactor is about 290°C, and the quality of the solid product produced is 65.7%. Gas accounts for 34.3% of biomass mass. Straw coke is gasified with water vapor in the gasification reactor, the inlet temperature of water vapor is 280°C, the ratio of pyrolysis coke to water vapor is 0.8, the excess oxygen coefficient is 0.35, the reaction temperature is 725°C, and the reaction pressure is 1.2 MPa, H in the gas returned from the gas separati...

Embodiment 3

[0052] The rice straw powder with an ash content of 16.32% was sprayed and soaked with the quenching liquid of gasification bottom ash and combustion ash, the mass ratio of biomass and quenching liquid was controlled at 1:0.5, and then dried to a moisture content of 10.7 %, the total content of potassium, sodium, calcium and magnesium elements is 4.8%. The rice straw is pyrolyzed in a spiral pyrolysis device, using flue gas at 430°C as indirect heat supply, the pyrolysis time is 10 minutes, the average temperature in the spiral reactor is about 300°C, and the quality of the solid product produced is 69.2%. It accounts for 30.8% of biomass mass. Rice straw pyrolysis coke is gasified with water vapor / oxygen under pressure in the gasification reactor, the inlet temperature of water vapor is 300°C, the mass ratio of rice straw pyrolysis coke to water vapor is 0.5, and the oxygen excess coefficient is 0.2. The temperature is 760°C, the reaction pressure is 3MPa, the H in the gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com