High-performance printable ink, preparation method thereof and application to flexible all-solid-state supercapacitor

A high-performance, flexible electrode technology, applied in the manufacture of electrolytic capacitors, hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the unstudied application of inkjet printing graphene oxide ink, reduce GO specific surface area and adsorption sites , reduce the overall performance of the device and other issues, and achieve excellent cycle stability, excellent electrochemical performance, and smooth ink output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

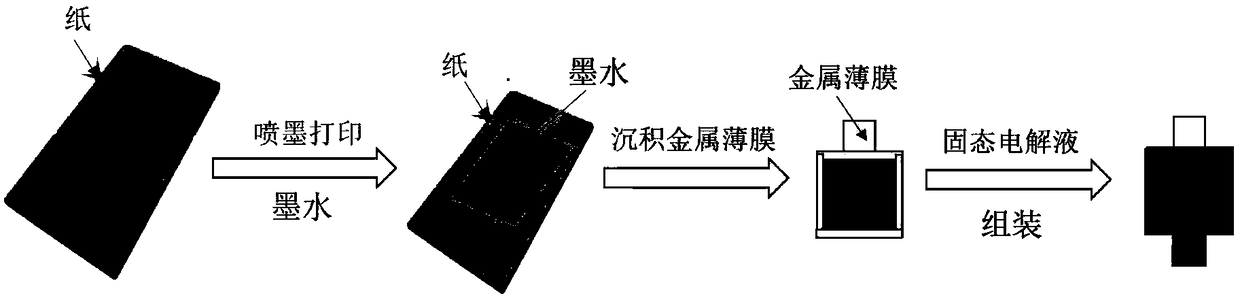

[0054] The present invention also provides a method for preparing the above-mentioned high-performance jet-printable ink, comprising the following steps:

[0055] Disperse carbon quantum dots and graphene oxide in a solvent, add a surfactant, mix and stir, then perform ultrasonication and centrifugation to obtain a high-performance jet-printable ink.

[0056] Wherein, the stirring time is 10-60min, preferably 20-40min, the ultrasonic treatment time is 30-120min, preferably 60-100min; the centrifugal rate is 2000rpm-10000rpm, preferably 6000-8000rpm, and the centrifugal time is 5-10min / time .

[0057] The present invention also provides a flexible electrode for a flexible all-solid-state supercapacitor, which is obtained by inkjet printing ink on the surface of a flexible substrate and then drying, and the ink is the above-mentioned high-performance jet-printable ink.

[0058] Wherein, the flexible substrate includes one or more of printing paper, weighing paper, mirror paper,...

Embodiment 1

[0081] Preparation of carbon quantum dots: Mix 100mg fullerene and 3g potassium hydroxide into a nickel crucible, and then put it into a tube furnace for high temperature activation reaction. The activation temperature is 600°C, the activation time is 10min, and the argon flow rate is 300sccm. After the reaction, quickly pull out the nickel crucible from the tube furnace, cool it at room temperature, wash it with deionized water, and filter it with a PTFE hydrophilic membrane with a pore size of 1 μm and 0.22 μm. The dialysis bag is dialyzed until the eluate is neutral, then the dialysate in the dialysis bag is evaporated in a water bath at a temperature of 60°C, and finally the evaporated solution is placed in a freeze dryer for freeze-drying to obtain carbon quantum Dot powder.

[0082] see figure 2 , figure 2 The middle picture (a) is the transmission electron microscope image of the carbon quantum dots prepared by the high-temperature activation method in Example 1. It...

Embodiment 2

[0084] Preparation of carbon quantum dots: Mix 100mg fullerene and 3g sodium hydroxide into a nickel crucible, and then put it into a tube furnace for high temperature activation reaction. The activation temperature is 700°C, the activation time is 6min, and the argon flow rate is 300sccm. After the reaction, quickly pull out the nickel crucible from the tube furnace, cool it at room temperature, wash it with deionized water, and filter it with a PTFE hydrophilic membrane with a pore size of 1 μm and 0.22 μm. The dialysis bag is dialyzed until the eluate is neutral, then the dialysate in the dialysis bag is evaporated in a water bath at a temperature of 60°C, and finally the evaporated solution is placed in a freeze dryer for freeze-drying to obtain carbon quantum Dot powder.

[0085] see figure 2 , figure 2 (b) is the transmission electron microscope image of the carbon quantum dots prepared by the high-temperature activation method of sodium hydroxide in Example 2. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com