Epoxy resin system, preparation method thereof and prepreg

An epoxy resin system and epoxy resin technology, applied in the field of composite materials, can solve the problems of unfavorable storage, transportation and use of prepregs, inability to store for a long time, low apparent activation energy, etc., and achieve stable, reliable and excellent performance. The effect of performance, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] (1) Preparation of epoxy resin

[0078] Preparation of component A: Take 10kg of solid epoxy resin E-20 and 4kg of liquid epoxy resin E-51 in a reactor and heat to 100°C and stir for 60 minutes. The solid epoxy resin is completely melted and fully mixed with the liquid epoxy resin. Then the reactor was cooled to 55°C and kept warm.

[0079] Preparation of component B: Take 6kg of liquid epoxy resin E-51 and put it into a mixer, add 3.6kg of Thinkhard 608K and 1kg of PN-23J, stir for 40min, and then grind twice through a three-roll mill to obtain a uniform mixture.

[0080] Epoxy resin system preparation: Add component B into component A reactor and stir at 55°C for 60 minutes to obtain an epoxy resin system.

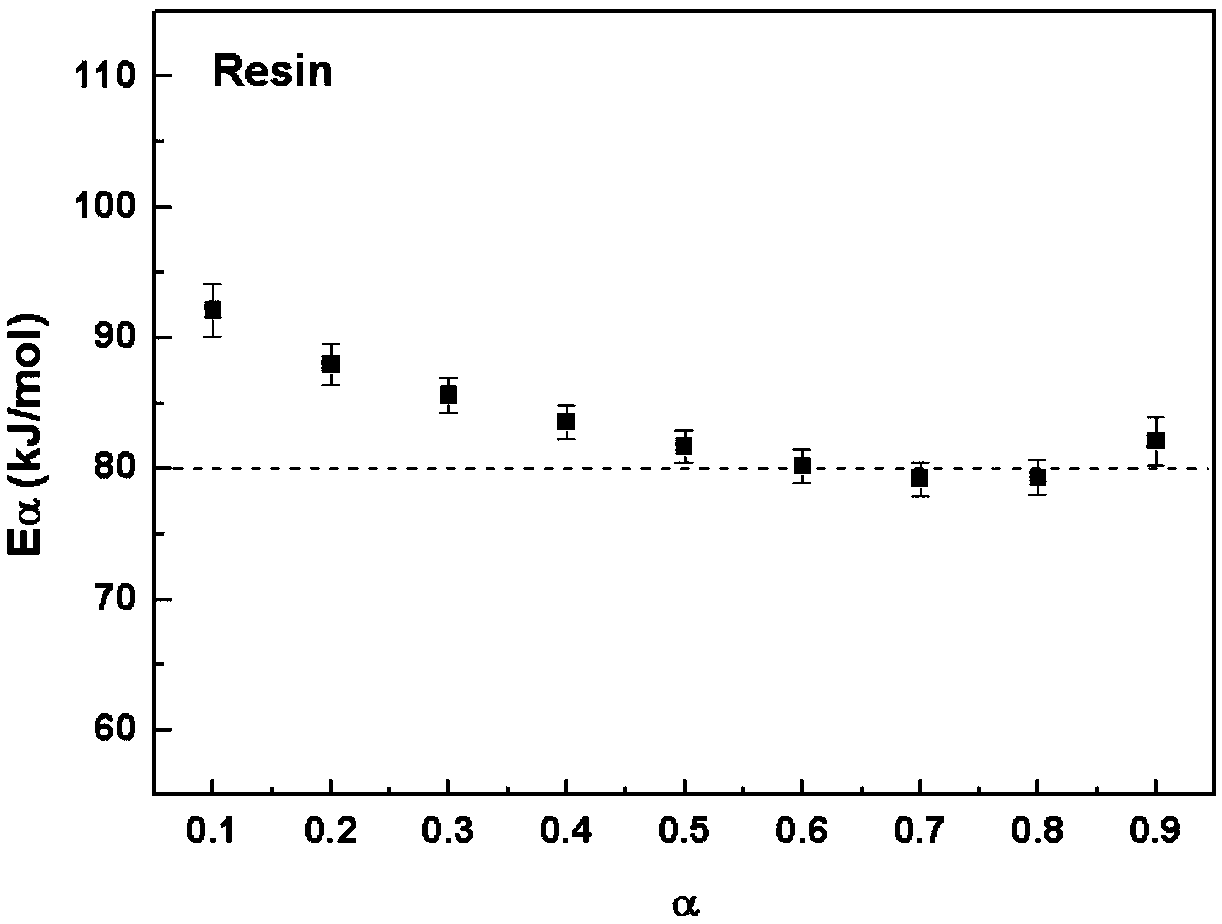

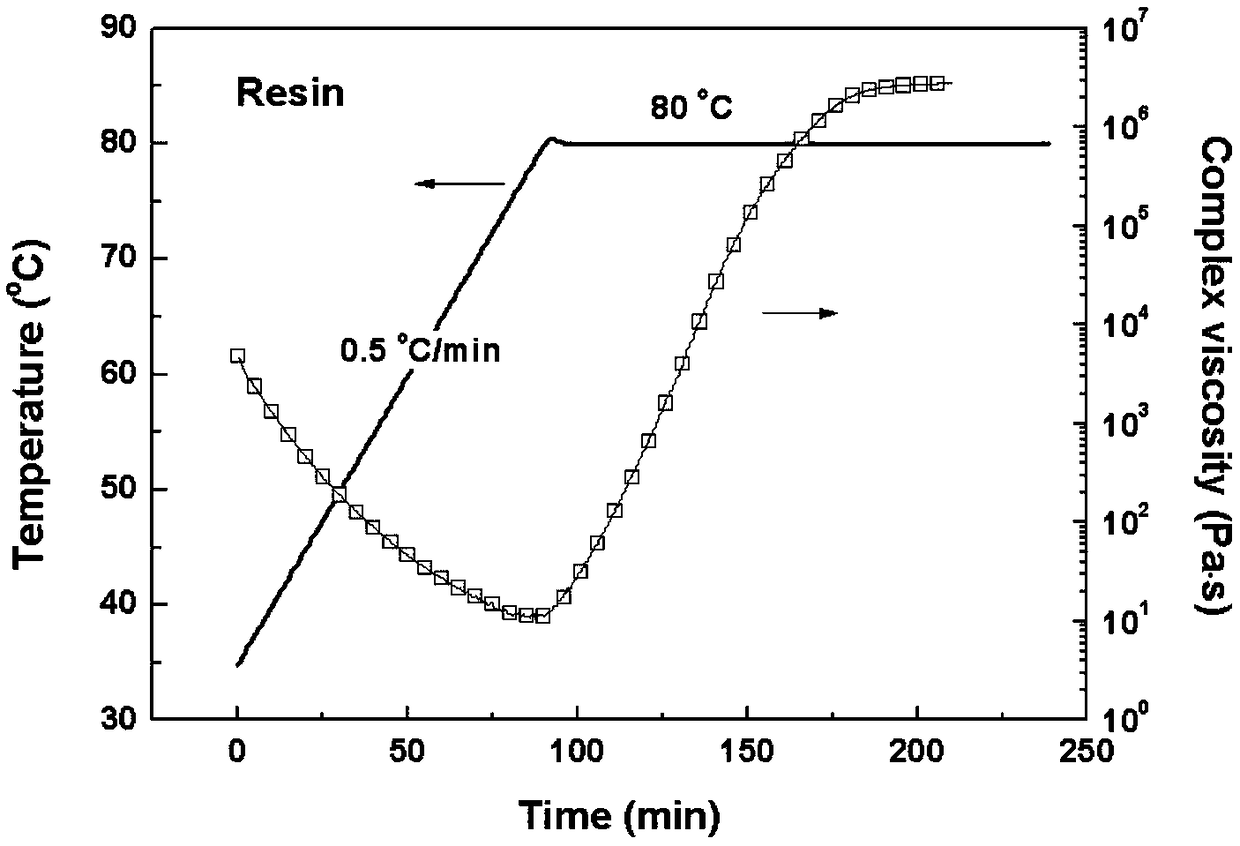

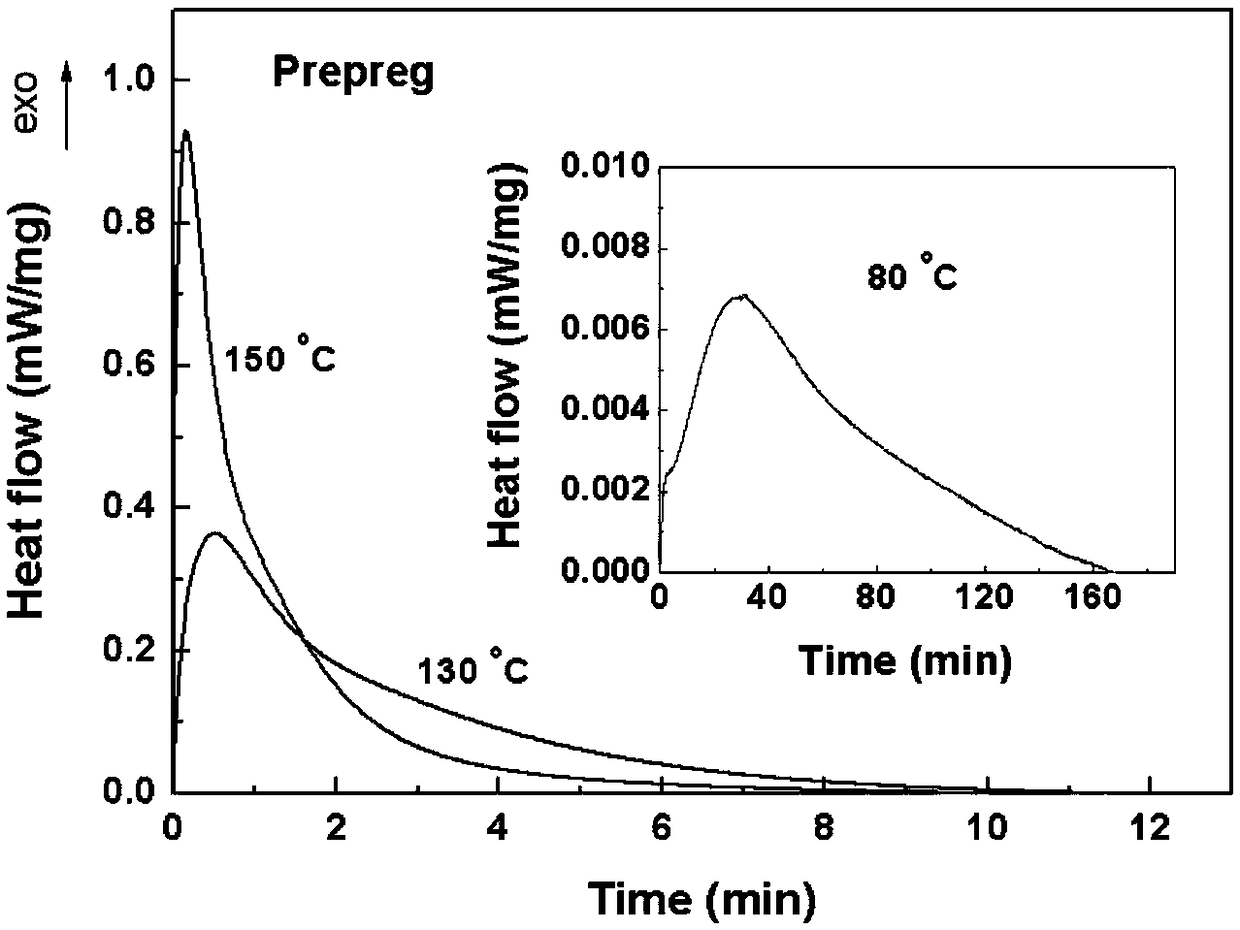

[0081] (2) Activation energy of curing reaction of resin system

[0082] Using Mettler-Toledo DSC1 to study the curing reaction of the resin system, the temperature range is 25 ~ 260 ° C, the heating rate is 5, 10, 15 and 20 ° C / min, the protection system is h...

Embodiment 2

[0092] (1) Preparation of epoxy resin

[0093] Preparation of component A: Take 4kg of solid epoxy resin E-20, 9kg of semi-solid novolak epoxy resin F-46 and 2kg of liquid epoxy resin E-51 in a reaction kettle, heat to 130°C and stir for 45min, wait for the solid and semi-solid The solid epoxy resin is completely melted and fully mixed with the liquid epoxy resin, and then the reaction kettle is cooled to 50°C to keep it warm.

[0094] Preparation of component B: Take 5kg of liquid epoxy resin E-51 and put it into a mixer, add 3.6kg of Thinkhard 608K and 1.2kg of PN-23J, stir for 50min, and then grind twice through a three-roll mill to obtain a uniform mixture.

[0095] Preparation of epoxy resin system: Add component B into component A reactor and stir at 50°C for 60 minutes to obtain an epoxy resin system.

[0096] (2) Activation energy of curing reaction of resin system

[0097] Adopt the method identical with embodiment 1, obtain the variation relation of activation ener...

Embodiment 3

[0105] (1) Preparation of epoxy resin

[0106] Preparation of component A: Take 5kg of four-functionality liquid epoxy resin S720 and 1.2kg of phenoxy resin JER4250 in a reaction kettle, heat to 130°C and stir for 90min. After the phenoxy resin is completely dissolved in the epoxy resin, add 6kg of solid Continue to stir the epoxy resin for 60 minutes. After the solid epoxy resin is completely melted and fully mixed, the reaction kettle is cooled to 60°C and kept warm.

[0107] Preparation of component B: Take 2kg of liquid epoxy resin E-51 and 5kg of liquid epoxy resin S720 and put them into the mixer, add 5kg of Thinkhard 608K and 1.2kg of PN-23J, stir for 50min, and then grind once with a three-roll mill A homogeneous mixture is obtained.

[0108] Preparation of epoxy resin system: Add component B into component A reactor and stir at 60°C for 25 minutes to obtain an epoxy resin system.

[0109] (2) Activation energy of curing reaction of resin system

[0110] Using the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com