Ship bottom silt removal robot

A robot and ship bottom technology, applied to ship cleaning devices, ship hulls, ship construction, etc., can solve problems such as heavy workload and long maintenance work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

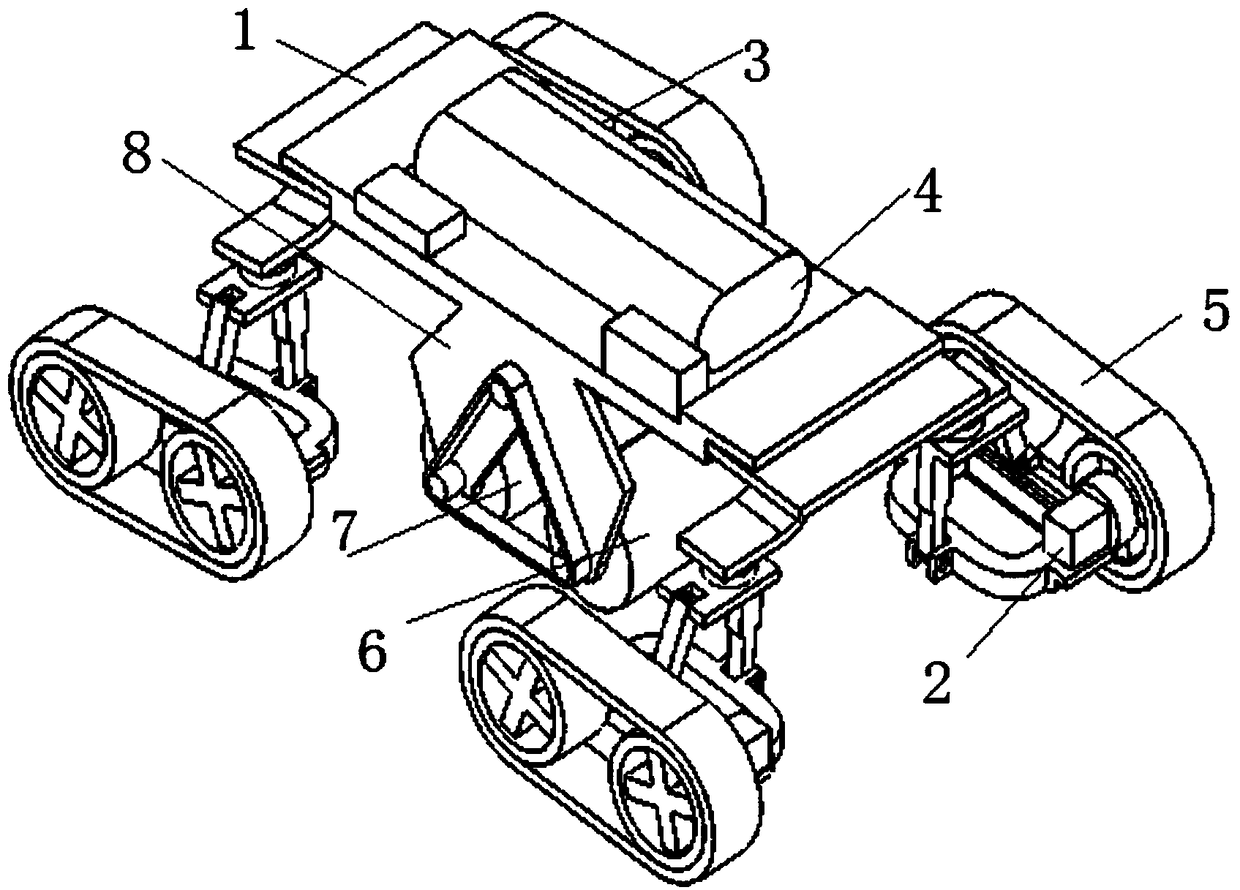

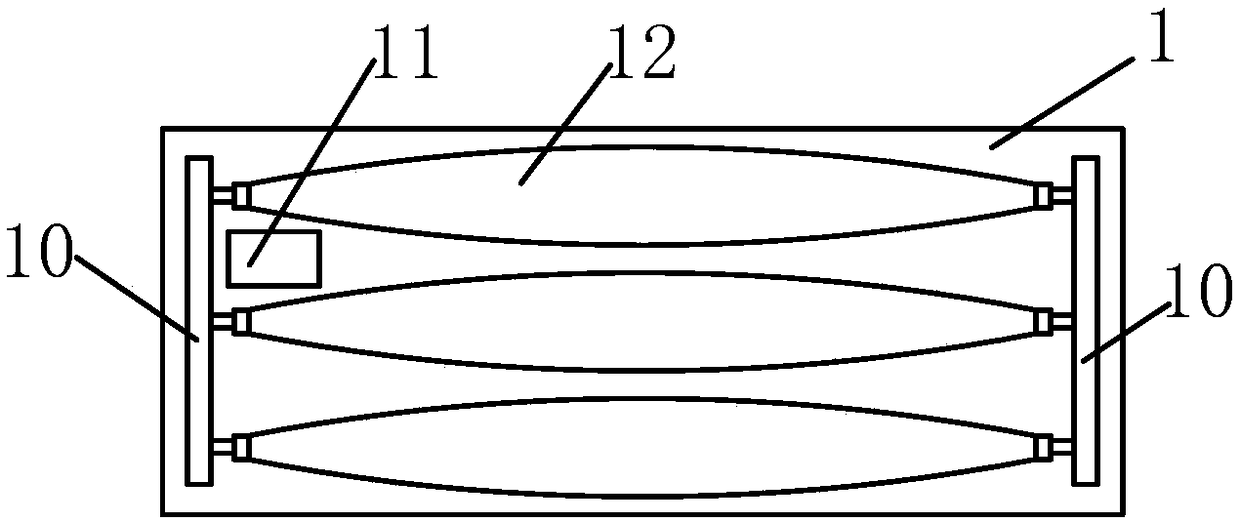

[0018] refer to figure 1 , the present invention proposes a ship bottom dredging robot for dredging the iron ship bottom, which includes a vehicle frame 1, four crawler walking mechanisms 3 placed on the vehicle frame 1, a buoyancy mechanism and a dredging mechanism. Both sides of the bottom of the vehicle frame 1 extend downward to form two wing plates 8 .

[0019] The four crawler running mechanisms 3 are respectively arranged at four corners of the vehicle frame 1 , and the crawler belt running mechanisms 3 include a first motor 2 and two magnetic wheels. The two magnetic wheels are connected through a crawler belt 5, and the magnetic wheels are at least partially made of magnetic materials. The first motor 2 is connected with the magnetic wheel for driving the magnetic wheel to rotate.

[0020] The dredging mechanism includes a first brush roller 6 and a second brush roller 7, and the axial direction of the first brush roller 6 and the second brush roller 7 is consistent...

Embodiment 2

[0031] The difference from Embodiment 1 is that in order to realize the intelligent control of the robot, the submarine transponder can be arranged in the planned working water area in advance. When the dredging robot is attached to the bottom surface of the ship, the interrogator embedded in the dredging robot sends out an inquiry signal and receives the signal from the transponder, and based on this, the distance between the dredging robot and each transponder is calculated. The absolute spatial position of the dredging robot can be calculated by using spherical intersection, so as to realize the positioning, and then the movement of the dredging robot can be planned independently or artificially controlled.

[0032] The whole vehicle frame 1 adopts 1060 aluminum alloy profile, which has low density and high strength, and is treated with anti-corrosion spray paint. The on-load motors are all selected underwater special models.

[0033] A control system processor is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com