Device for artistic engraving

A kind of art and knife handle technology, applied in the field of engraving, can solve the problems that the carving knife cannot be polished, the knife head is easy to loose, and the debris cannot be blown out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The specific implementation process is as follows:

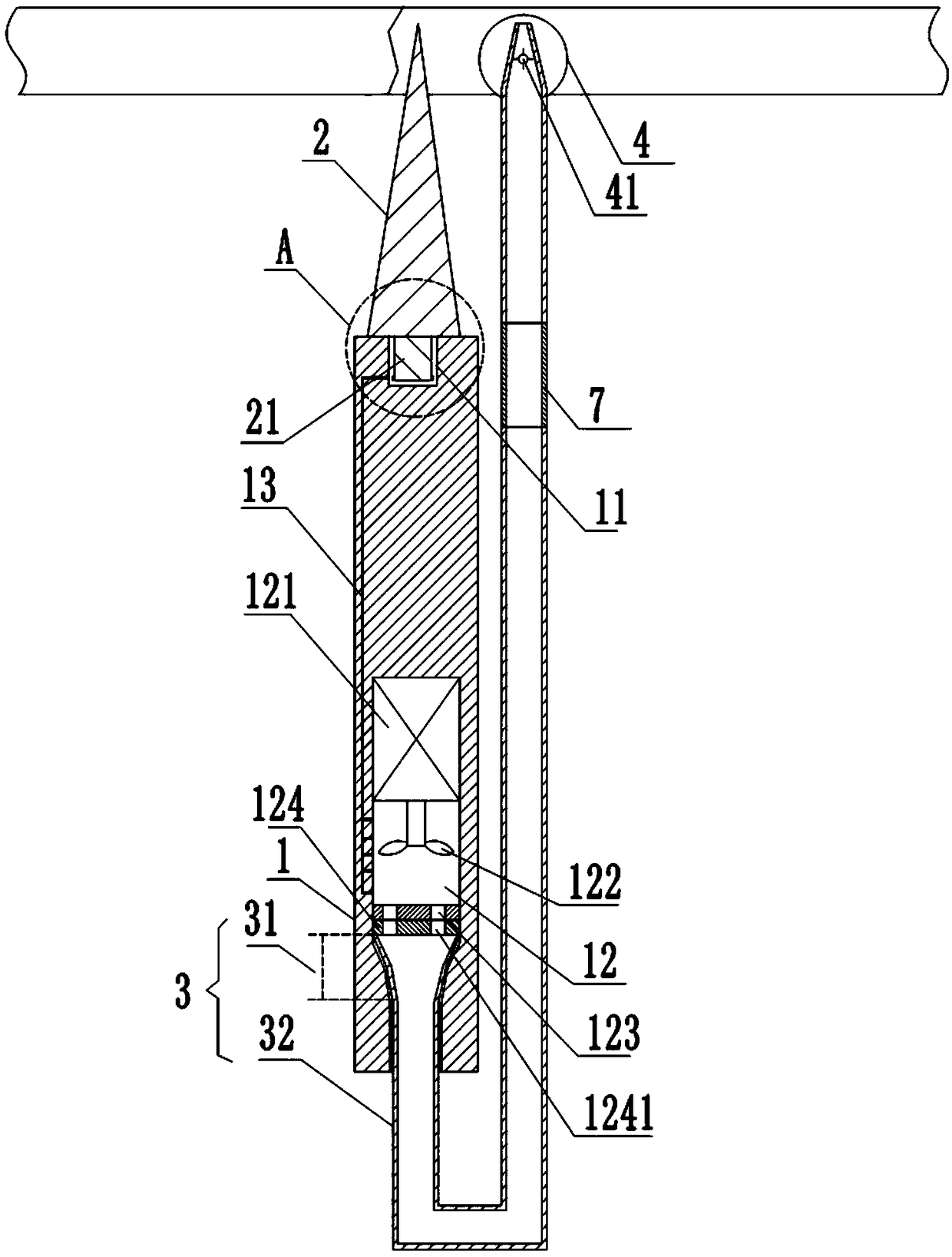

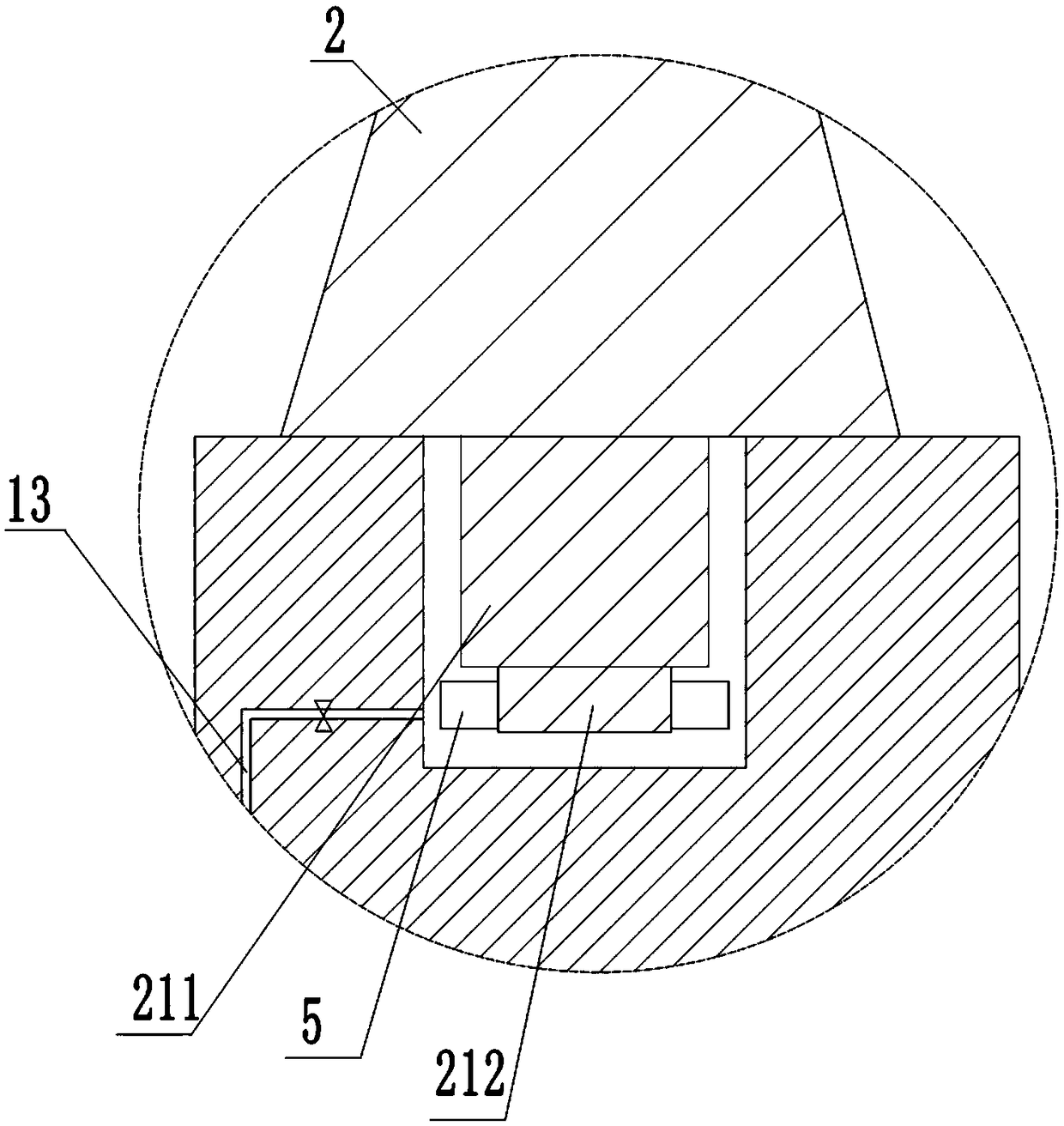

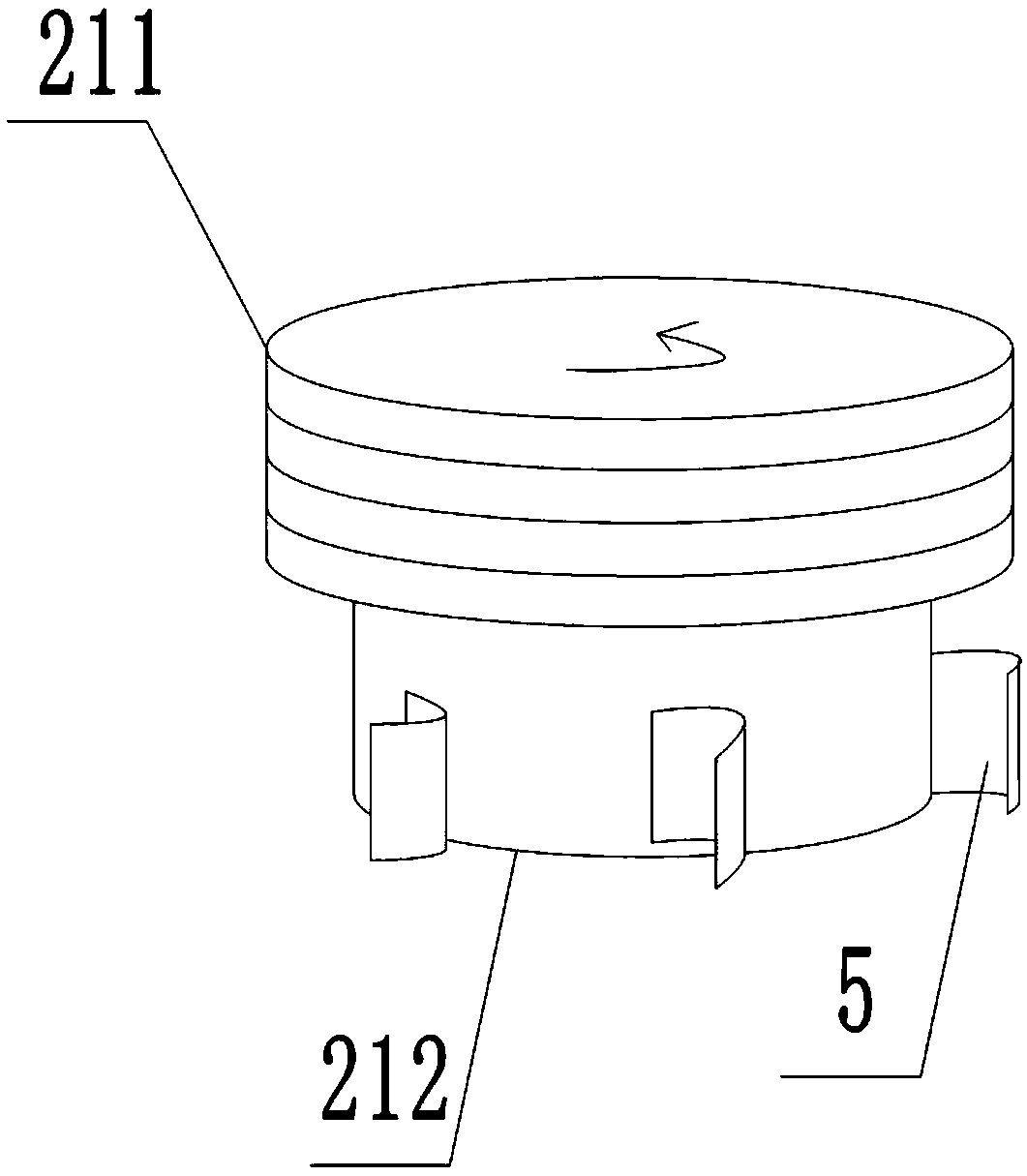

[0041] A device for artistic engraving, such as figure 1 , including a handle 1, a cutter head 2 and a chip removal pipe 3; Threaded in the threaded groove 11. like figure 2 and image 3 , the threaded rod 21 comprises a cylindrical threaded rod body 211 and a cylindrical end 212, the threaded rod body 211 is provided with external threads; the cylindrical end 212 is fixed on the lower end of the threaded rod body 211; and the diameter of the threaded rod body 211 greater than the diameter of the cylindrical end 212. An arc-shaped tab 5 is fixed on the circumference of the cylindrical end 212 .

[0042] In addition, in order to ensure that the cutter head 2 extends into the threaded groove 11, there is a larger space for air supply, and the depth of the threaded groove 11 is greater than or equal to the length of the threaded rod 21. Of course this can be set as required, when the depth of the threaded groove 1...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that, if Figure 4 , Figure 5 and Image 6 , the cavity wall at the bottom of the air chamber 12 is provided with an arc-shaped mouth 6 and a folding telescopic layer 61, and the arc-shaped mouth 6 is sealed by a folding telescopic layer 61; The cut-off plate 62 passes through the folded telescopic layer 61 and is fixedly connected thereto. The outer wall of the cut-off plate 62 is in close contact with the wall of the wind chamber 12 , for example, if the wind chamber 12 is cylindrical, the cut-off plate 62 is arc-shaped to match the wall of the wind chamber 12 . The folding and stretching layer 61 in this solution is a corrugated rubber layer or a corrugated metal sheet layer.

[0053] During use, when the blowing holes 1241 on the rotating disk 124 do not correspond to the air outlet holes 123, the wind in the air chamber 12 will all enter into the air supply pipe 13, thereby realizing the tightening acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com