A kind of high-performance flux for lead-acid battery and preparation method thereof

A lead-acid battery and flux technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as unsatisfactory wetting effect, poor solder joint firmness, unsatisfactory solder joint conductivity, etc., and achieve excellent phase Capacitance, excellent temperature resistance, and the effect of improving the soldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A high-performance soldering flux for lead-acid batteries proposed by the present invention comprises the following raw materials in parts by weight: 3 parts of chlorogenic acid, 4 parts of 1-dodecyl-3-methylimidazole nitrate, tetrakis(hexadecane Thio) tetrathiafulvalene 0.2 parts, silane coupling agent 2 parts, epoxy modified acrylic resin 8 parts, surfactant 2 parts, (2,4,6-trimethylbenzoyl) diphenyl 0.25 parts of phosphine oxide, 13 parts of 2-phenylethylamine, 26 parts of ethanol, and 52 parts of water; the epoxy-modified acrylic resin is a resin obtained by modifying the acrylic resin with water-based epoxy resin as the main body;

[0022] Its preparation method comprises the following steps:

[0023] S1. Weigh the raw materials of the high-performance soldering flux for lead-acid batteries and set aside;

[0024] S2. Add the weighed tetrakis(hexadecylthio)tetrathiafulvalene into the silane coupling agent, and disperse evenly to obtain the mixture A, which is set ...

Embodiment 2

[0028] A high-performance soldering flux for lead-acid batteries proposed by the present invention comprises the following raw materials in parts by weight: 2 parts of chlorogenic acid, 2 parts of 1-dodecyl-3-methylimidazole nitrate, 2 parts of tetrakis(hexadecane) Thio) tetrathiafulvalene 0.1 part, silane coupling agent 1 part, epoxy modified acrylic resin 5 parts, surfactant 1 part, (2,4,6-trimethylbenzoyl) diphenyl 0.2 parts of phosphine oxide, 3 parts of 2-phenylethylamine, 20 parts of ethanol, and 40 parts of water; the epoxy-modified acrylic resin is a resin obtained by modifying the acrylic resin with water-based epoxy resin as the main body;

[0029] Its preparation method is with embodiment 1.

Embodiment 3

[0031] A high-performance soldering flux for lead-acid batteries proposed by the present invention comprises the following raw materials in parts by weight: 4 parts of chlorogenic acid, 6 parts of 1-dodecyl-3-methylimidazole nitrate, tetrakis(hexadecane Thio) tetrathiafulvalene 0.3 parts, silane coupling agent 3 parts, epoxy modified acrylic resin 10 parts, surfactant 3 parts, (2,4,6-trimethylbenzoyl) diphenyl 0.3 parts of phosphine oxide, 6 parts of 2-phenylethylamine, 30 parts of ethanol, and 60 parts of water; the epoxy-modified acrylic resin is a resin obtained by modifying the acrylic resin with water-based epoxy resin as the main body;

[0032] Its preparation method is with embodiment 1.

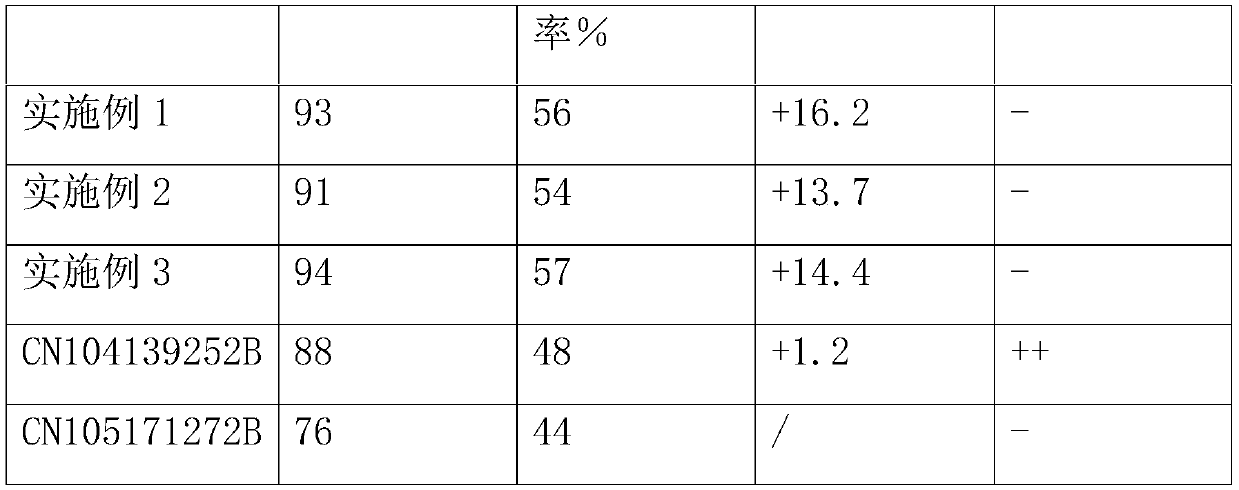

[0033] The fluxes prepared in Examples 1-3 and the fluxes prepared in accordance with Chinese patent authorization announcement number: CN104139252B (inorganic flux) and Chinese patent authorization announcement number: CN105171272B (organic flux) were tested for performance, and used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com