Method for performing milling microgroove machining by utilizing ultrafast laser

An ultrafast laser and milling technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of sacrificing groove depth and aspect ratio to increase thermal effects, and achieve the improvement of ablation threshold, reduction of width, calculation of small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

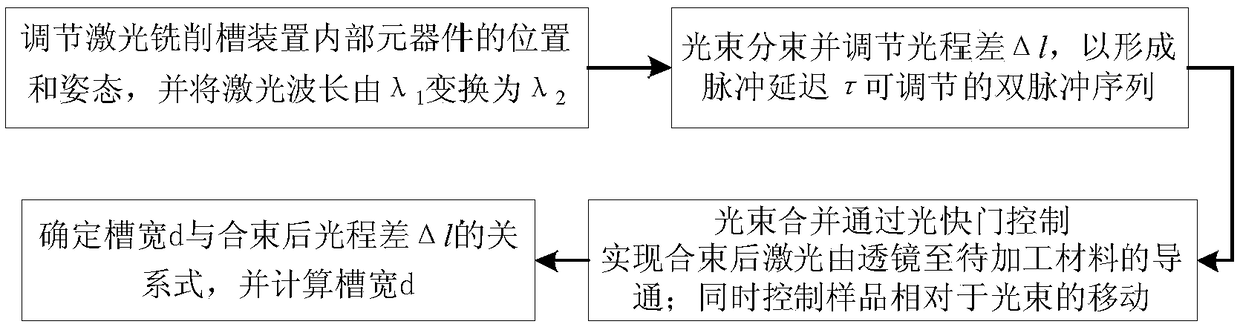

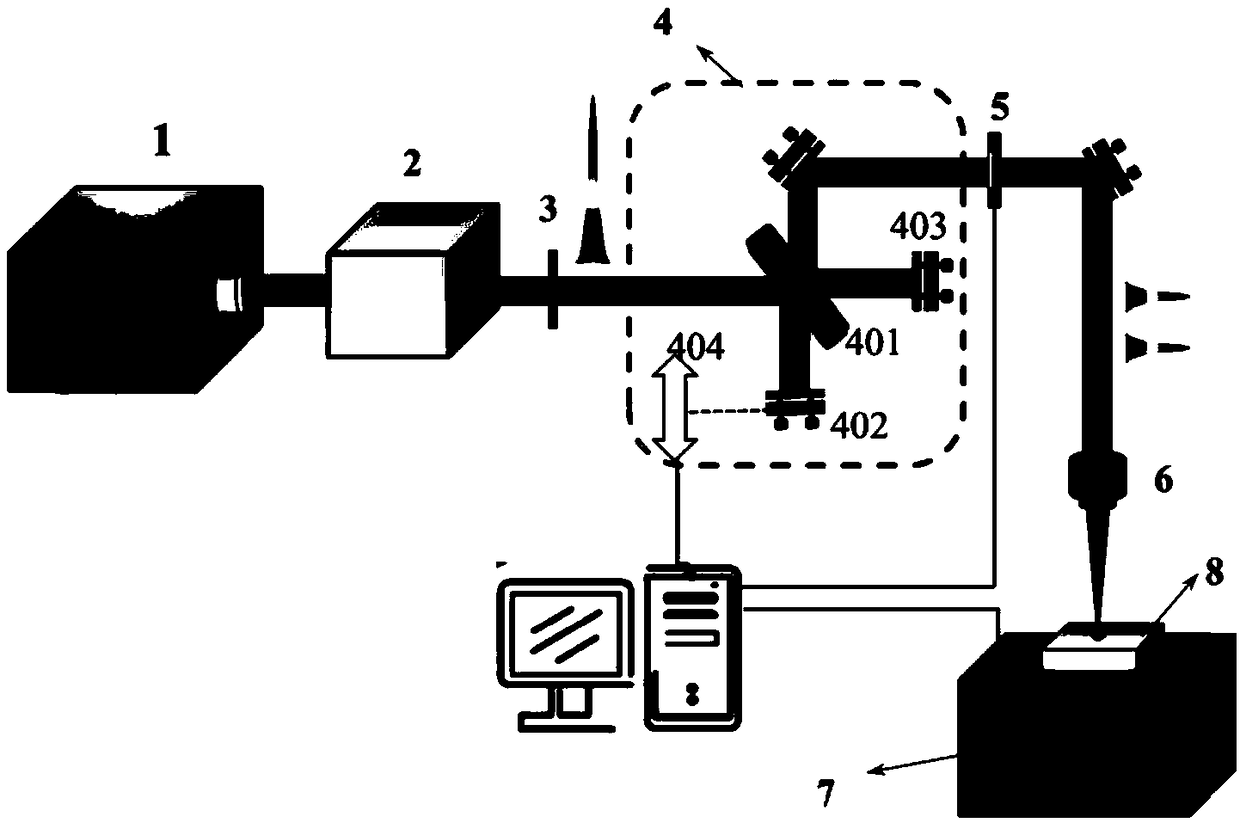

[0024] A method for milling microgrooves using ultrafast lasers, such as figure 2 As shown, by utilizing a laser milling slot comprising a laser 1, an optical parametric amplifier 2, an energy attenuation sheet 3, a Michelson interferometer 4, a linear translation stage 404, an optical shutter 5, a focusing lens 6, and a six-degree-of-freedom translation stage 7 The system performs laser groove cutting on the material 8 to be processed, and changes the single-pulse sequence laser to a double-pulse sequence laser to reduce the width of the milling groove and obtain an accurate value of the milling groove width through calculation, such as figure 1 As shown, the specific steps are as follows:

[0025] Step 1: Adjust the position and attitude of the internal components of the laser milling groove device, turn on the laser 1, measure the wavelength of the laser input laser according to the optical parameter amplifier 2, and convert the input wavelength λ1 of the input laser into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com