Ladle Drainage Method

A technology of ladles and diverters, which is applied in metal processing equipment, manufacturing tools, casting molten material containers, etc., can solve the problems of affecting the purity of molten steel, failing to reflect the economic value of molten steel, reducing the purity of molten steel, etc., to achieve Reduce the excess of ladle, reduce the height of slag volume, and ensure the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

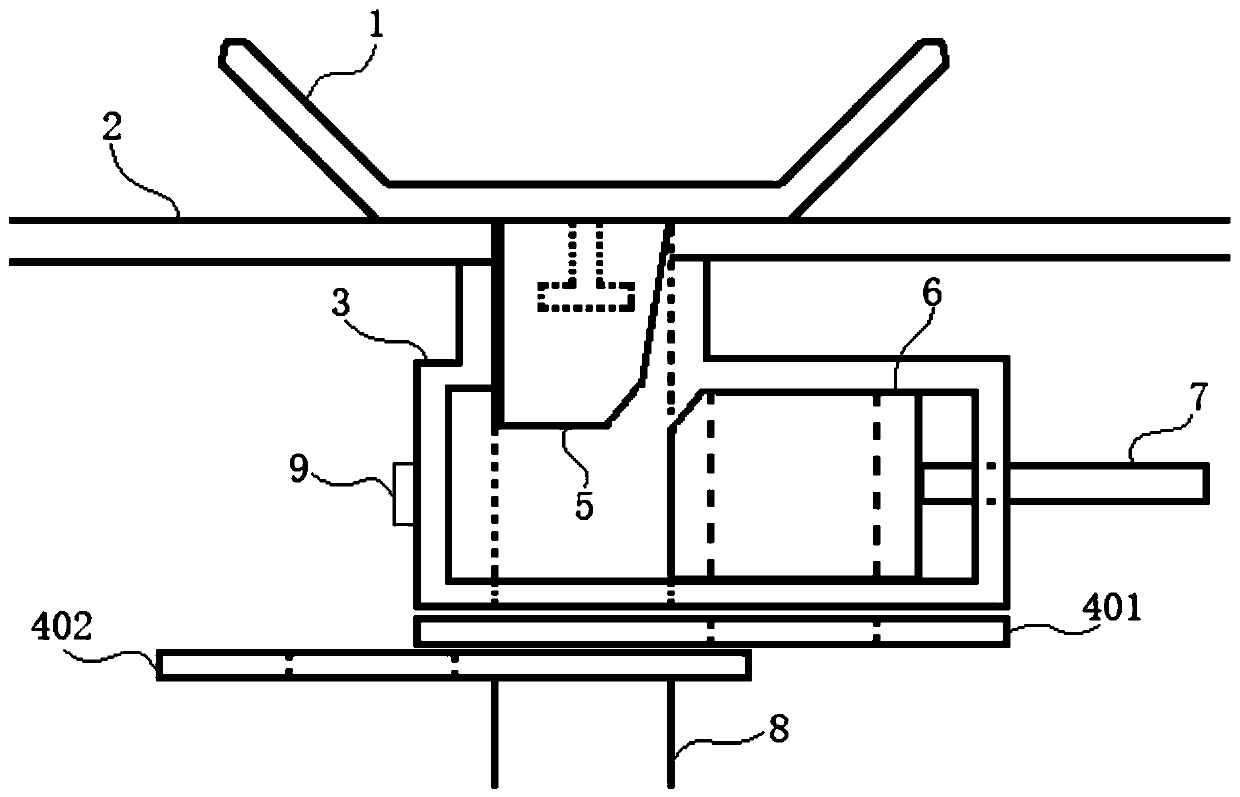

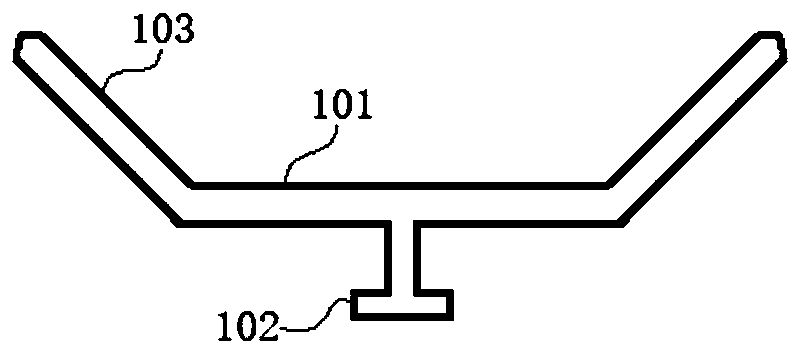

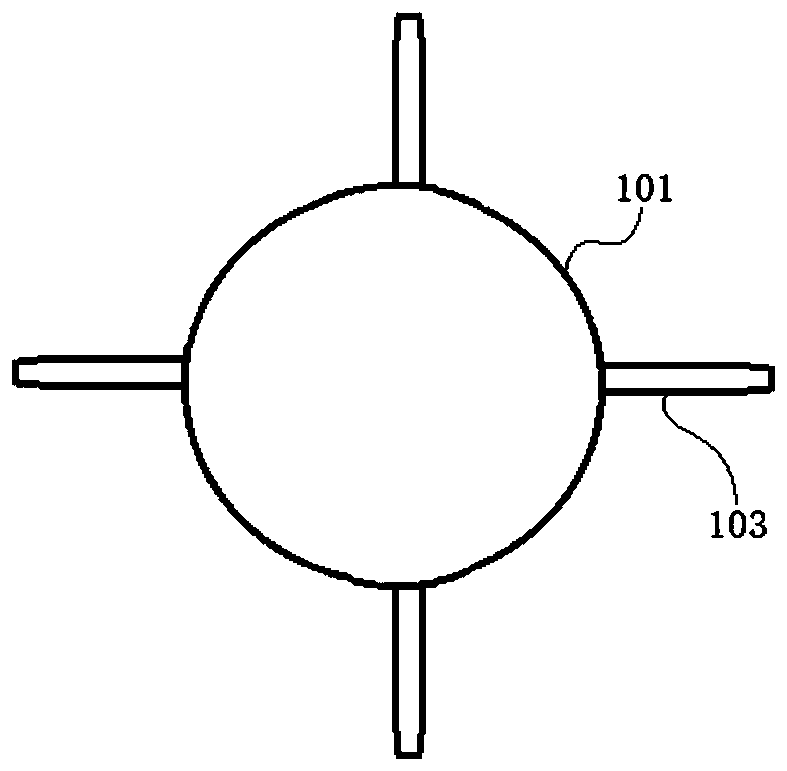

[0052] Combine Figure 1-6 , The ladle drainage and swirl suppression device of this embodiment includes: a drainage device 3, the upper end of the drainage device 3 is provided with a drainage device inlet 301, the lower end of the drainage device 3 is provided with a drainage device outlet 302, and the drainage device 3 is from the drainage device inlet 301 forms a drainage channel toward the direction of the drain outlet 302; the drainage channel in the drain 3 is provided with a containing cavity one 303 and a containing cavity two 304 respectively; swirl suppressor 1, swirl suppressor 1 includes swirl suppressing disc 101, The lower end of the swirling disc 101 is connected with a T-shaped joint piece 102, which is placed inside the nozzle plug 5. The nozzle plug 5 can be inserted into the drainage channel from the drain inlet 301; the swirling disc 101 is connected with several upward The supporting member 103 extending square; and the drainage part 6, the drainage part 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com