A battery automatic cleaning and drying device

An automatic cleaning and battery technology, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of destroying the working environment of the conveyor belt and unfavorable environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

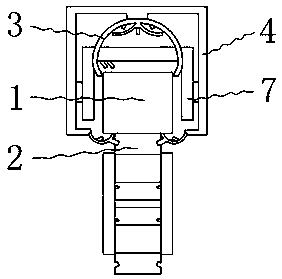

[0064] The specific embodiment: when people use the storage battery 1 cleaning and drying device designed by the present invention, when the drive motor is working, the drive motor will drive the drive wheel 6 connected to it in the two drive wheels 6 to rotate through the output shaft; The rotation of the wheel 6 drives the belt 5 to move; the movement of the belt 5 drives the support mechanism 2 mounted on it to move; the battery 1 is placed on the upper side of the support mechanism 2; the movement of the support mechanism 2 will drive the battery 1 to move; during the movement of the battery 1, When the accumulator 1 moved to the inside of the cleaning support shell 3, the first spray nozzle 12 and the second spray nozzle 13 installed on the cleaning support shell 3 were controlled to spray cleaning liquid, and the third spray nozzle 15 installed on the arc support plate 10 was controlled simultaneously. Eject cleaning solution; the dilute sulfuric acid adhered to the batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com