RTV coating spraying technology for transformer substation post insulator

A technology for pillar insulators and substations, which is applied in the field of insulator coating spraying technology, which can solve the problems that the uniformity of coating thickness cannot be guaranteed, the coating quality is difficult to guarantee, and the construction personnel are not safe, so as to improve the quality of RTV coating and reduce the manufacturing cost. , Improve the effect of spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

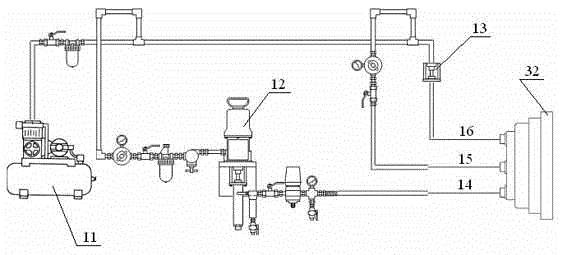

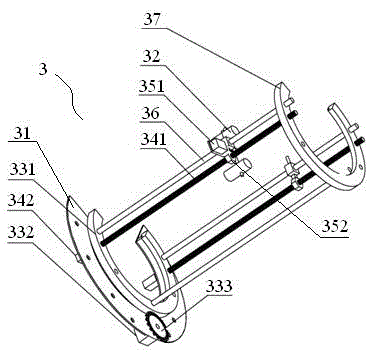

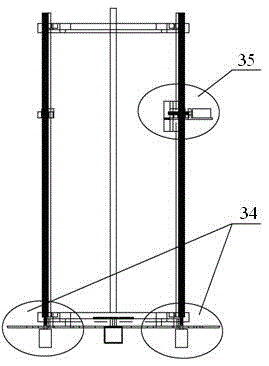

[0040] The invention discloses an RTV paint spraying process for substation post insulators. The spraying process is based on spraying equipment to complete the spraying operation. The structure of the spraying equipment is as follows: Figure 1 to Figure 5 As shown, it includes a spraying pressure system 1 and a spraying device with a spray gun 32 , and the spraying device completes the spraying operation of substation post insulators under the control of the spraying pressure system 1 .

[0041] The structure of the spraying pressure system 1 is as follows: figure 1 As shown, an air compressor 11 , a storage tank 12 , a spray pump and a controller 13 are included. The air compressor 11 communicates with the spray gun 32 through the air supply pipeline 15; the storage tank 12 communicates with the spray gun 32 through the paint pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com