Construction waste sorting device

A sorting device and technology for construction waste, applied in the directions of magnetic separation, solid separation, grain processing, etc., can solve the problems of resource reuse and achieve convenient collection, reasonable structure design, and the effect of ensuring physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

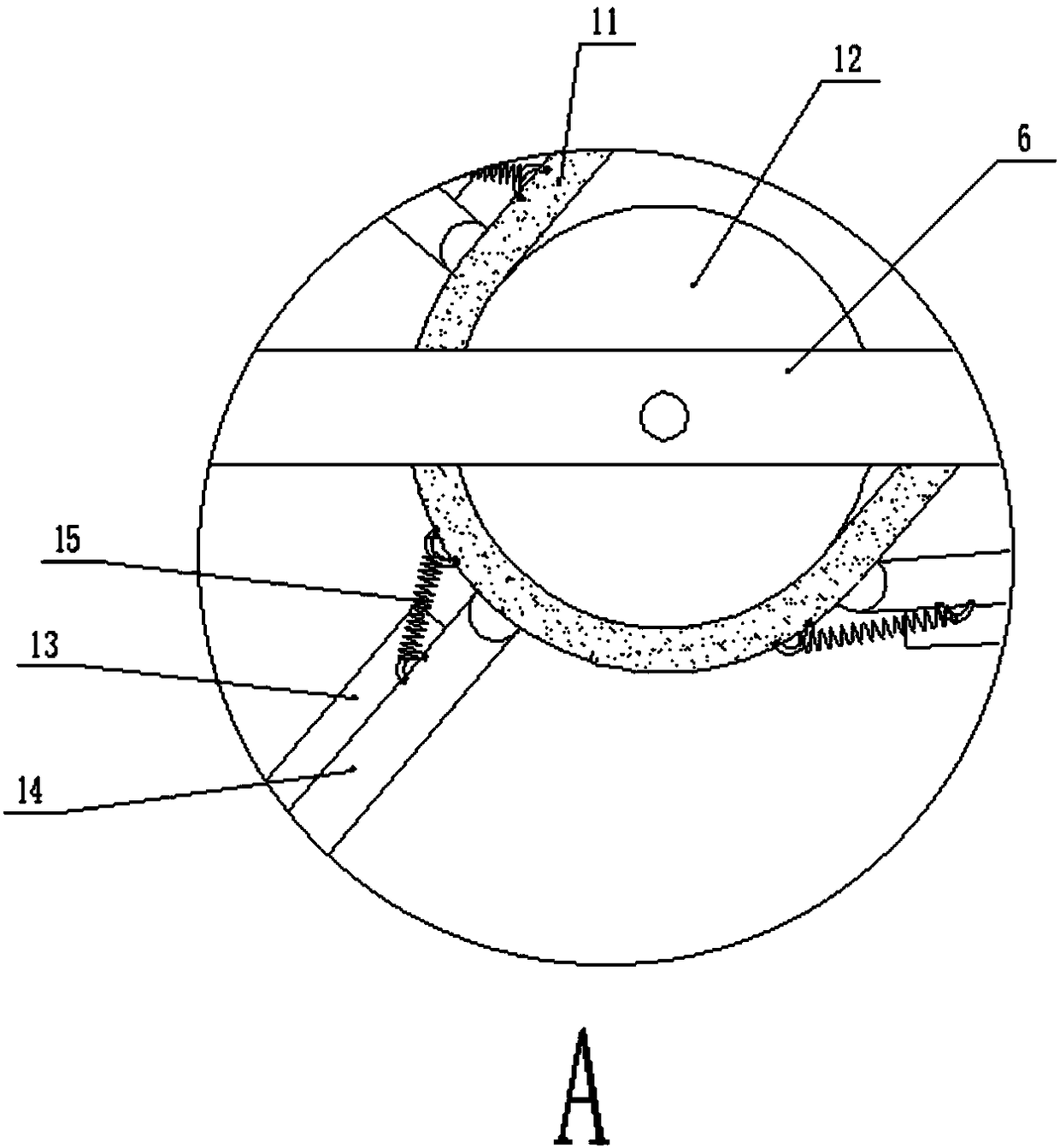

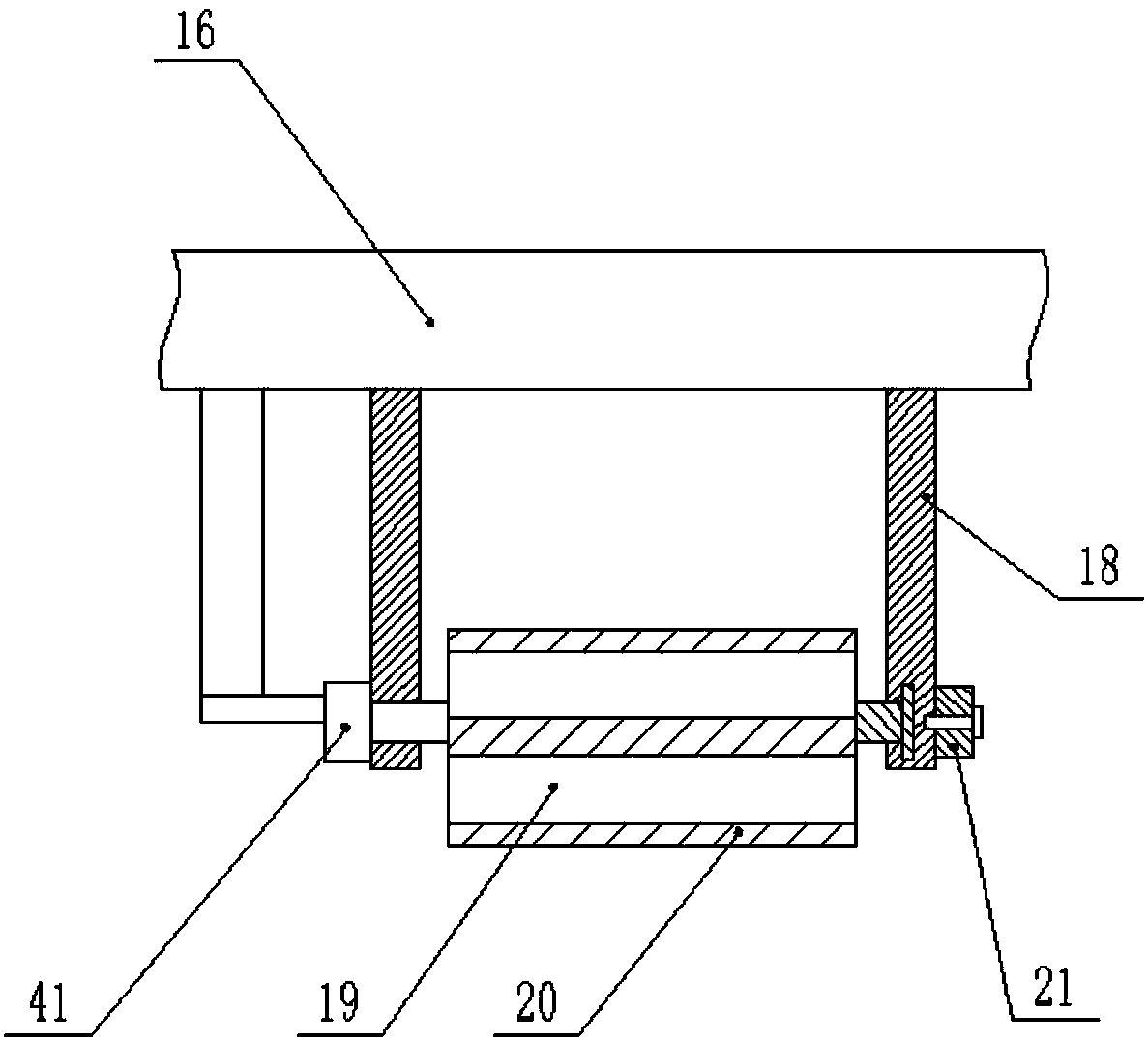

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a sorting device for construction waste includes a bottom plate 1, a fixed support rod 2 is fixed on the top of the bottom plate 1, and a conveying bucket 3 is fixedly arranged on the top of the fixed support rod 2, and the conveying bucket 3 is provided with There is a conveying screw 4, the connecting shaft of the conveying screw 4 passes through the lowest end of the conveying barrel 3 and is fixedly connected with the output end of the motor A5, and the motor A5 is fixedly connected with the positioning cross bar 6 through the connecting rod, and the positioning cross bar 6 is connected with the The topmost end of the conveying barrel 3 is fixedly connected, the lowest end side of the conveying barrel 3 is fixedly provided with a feed pipe 7, the upper end of the feed pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com