Secondary battery negative electrode, preparation method of secondary battery negative electrode and secondary battery

A secondary battery and negative electrode technology, applied to battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of electrolyte consumption, high processing cost, and complicated processing technology, and achieve reduced decomposition, high product consistency, and safety good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The second aspect of the embodiment of the present invention provides a method for preparing a negative electrode of a secondary battery, including:

[0044] Provide a metal foil raw material, chemically react the metal foil raw material with a solution containing phosphate radicals or form a dense metal phosphate film on the surface of the metal foil raw material by means of deposition, and obtain a secondary battery negative electrode;

[0045] The negative electrode of the secondary battery includes a metal foil and a dense metal phosphate film arranged on the surface of the metal foil. The metal foil is also used as a negative electrode current collector and a negative electrode active material. The material of the metal foil includes aluminum, copper, Any one of iron, tin, zinc, nickel, manganese, lead, antimony, cadmium and bismuth, or an alloy containing at least one of the above metal elements; the material of the metal phosphate film includes aluminum phosphate,...

Embodiment 1-38

[0078] A method for preparing a negative electrode of a secondary battery, comprising:

[0079] Soak an aluminum foil with a thickness of 50 microns in a phosphoric acid solution with a mass fraction of 50% for 60 minutes, then wash the reacted aluminum foil with pure water three times, place it in an oven, and dry it at a constant temperature for 300 minutes at a temperature of 80°C to obtain Secondary battery negative pole. Finally, the processed negative electrode of the secondary battery is cut into required negative electrode sheets according to the design requirements of the battery.

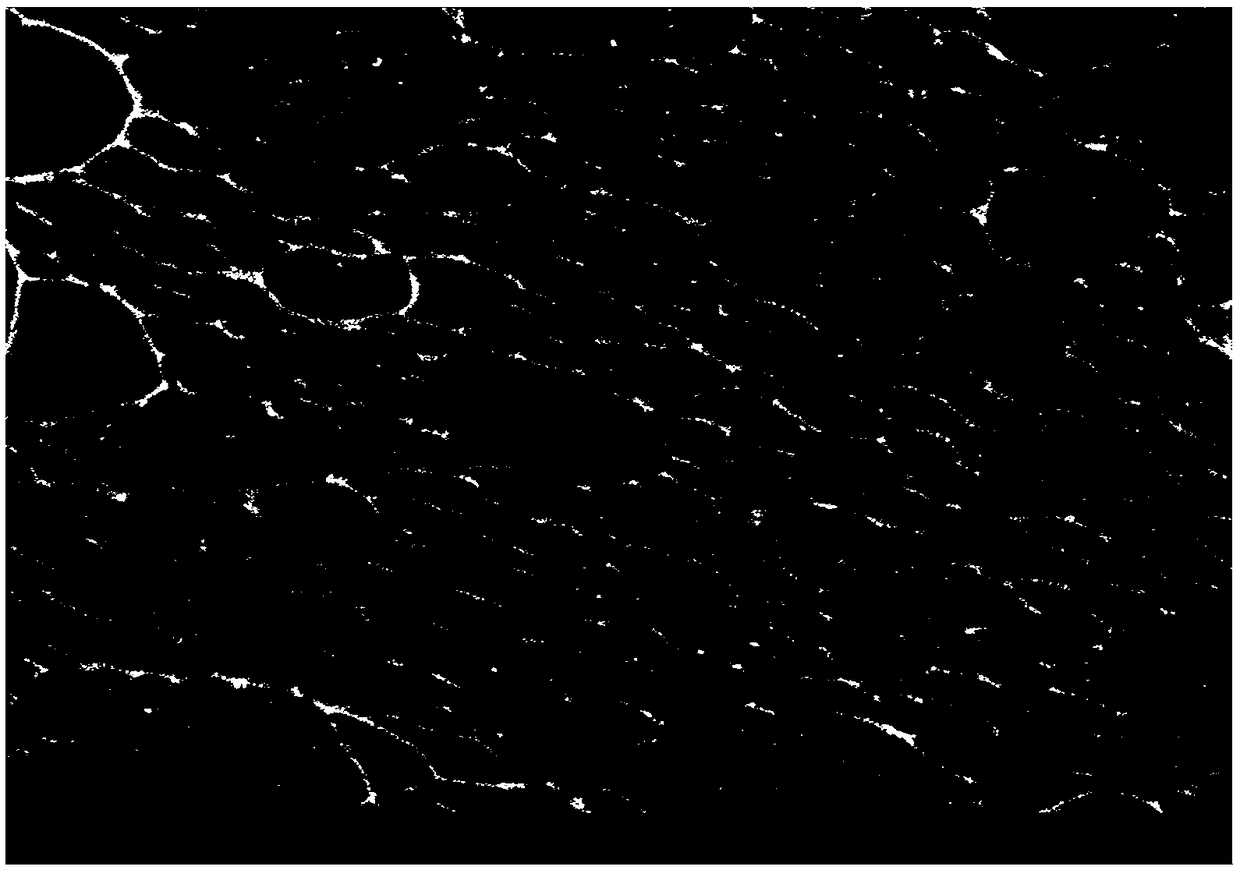

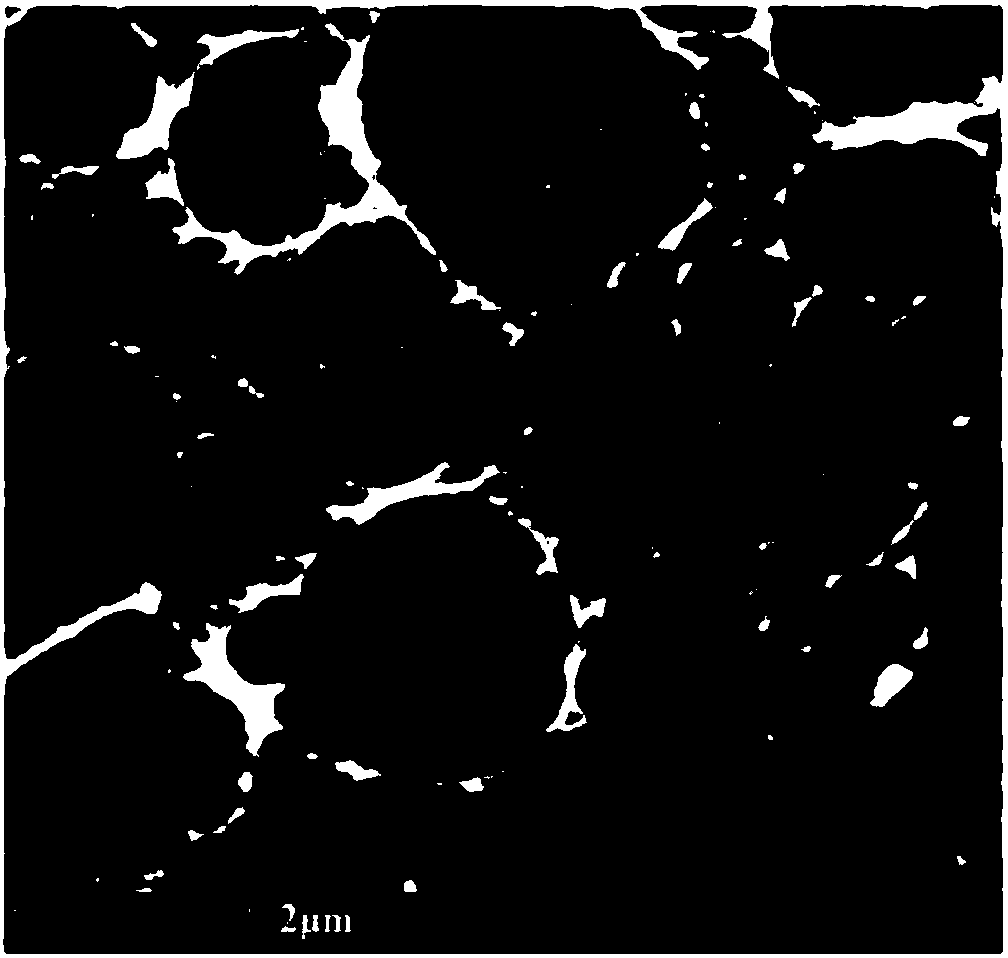

[0080] figure 1 It is a scanning electron microscope (SEM) picture of common aluminum foil; figure 2 It is the SEM picture of the secondary battery negative pole that is made in embodiment 1 of the present invention; image 3 An enlarged view of the SEM image of the negative electrode of the secondary battery prepared in Example 1 of the present invention; as figure 1 , figure 2 , ...

Embodiment 1-16

[0106] In the embodiment of the present invention, foil materials of different materials and graphite are assembled into a battery for forming tests. For each foil material, a comparison between non-phosphoric acid treatment and phosphoric acid treatment is carried out. The specific preparation and testing methods can refer to the examples. 1, adjust the relevant parameters to get different implementation cases. The specific assembly test results are shown in Table 3.

[0107] Table 3 embodiment parameter data and performance test result

[0108]

[0109] It can be seen from Table 3 that the initial efficiency and cycle performance of the battery after the battery is assembled with the negative electrode obtained after the phosphoric acid treatment of the metal foils of different materials are effectively improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com