Spherical body longitudinal single-weld seam all-welded ball valve

A fully welded ball valve and spherical body technology, applied in the valve details, valve device, valve shell structure, etc., can solve the problems affecting product safety performance and service life, affecting the service life of the valve, and the overall weight of the product. The effect of high value, blank weight saving, and less machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

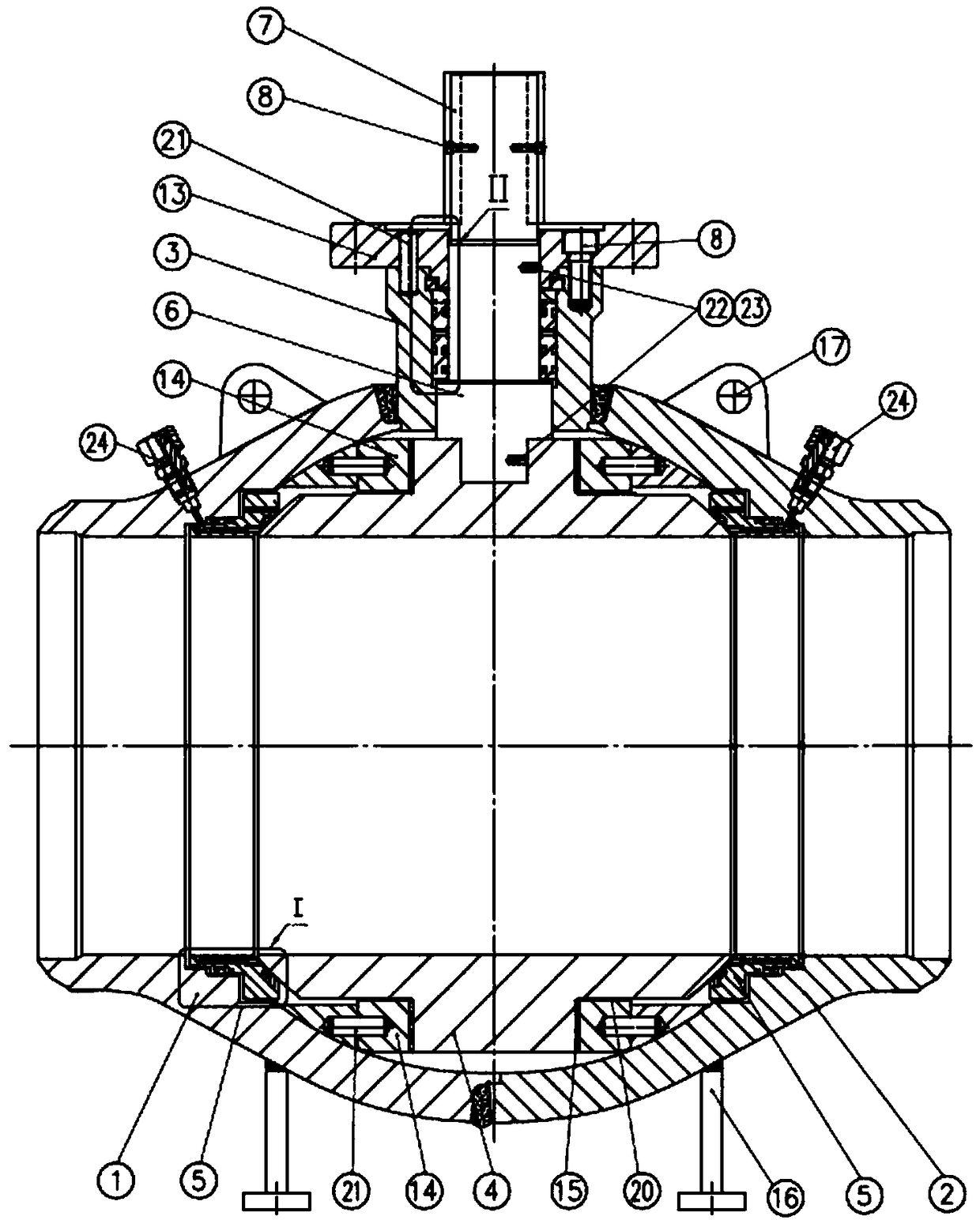

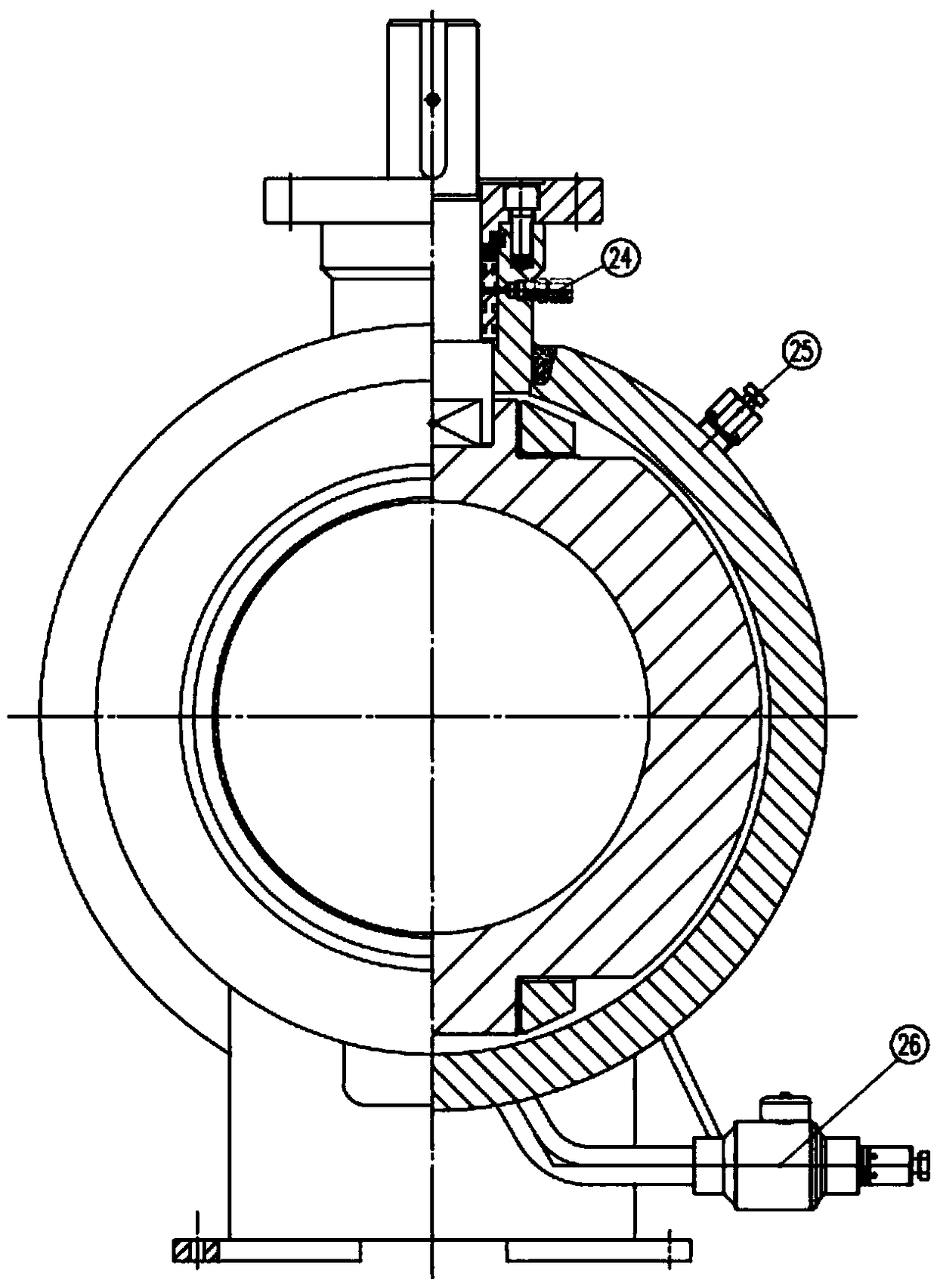

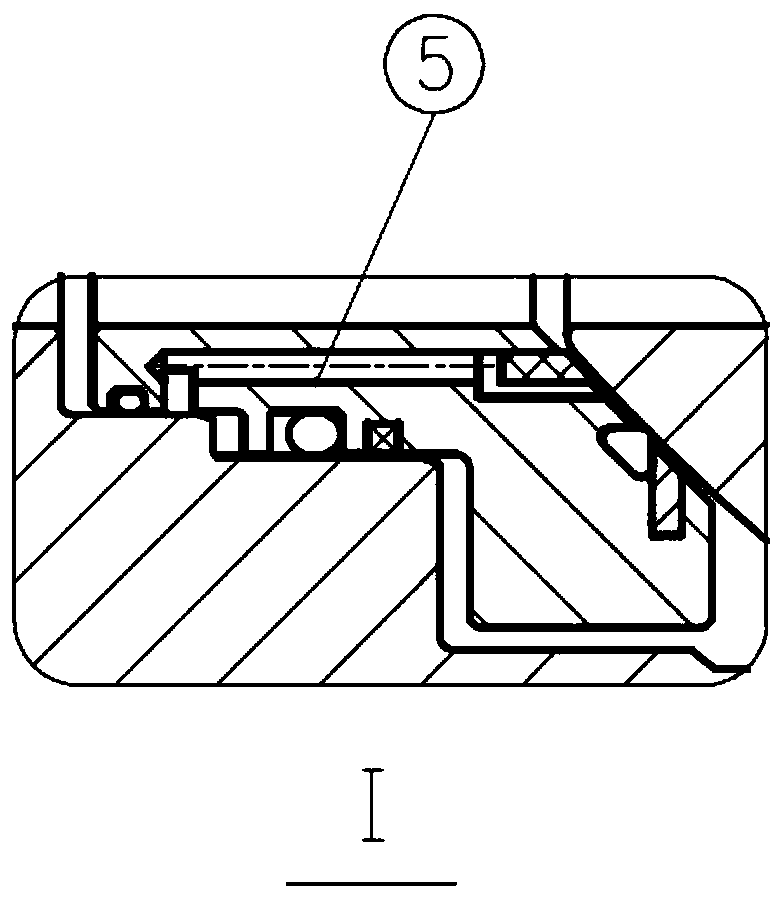

[0032] The present invention uses a sphere with a circular passage as the opening and closing member, and the sphere rotates 90 degrees around the axis of the valve stem with the rotation of the valve stem to realize the purpose of opening and closing. Such as Figure 1-3 As shown, the present invention includes a left valve body 1 and a right valve body 2, the valve seat assembly 5 is installed in the left valve body 1 and the right valve body 2 respectively, and the bearing pad 20 is in a clearance fit with the ball 4, so The bearing 15 is installed on the support plate 14 and closely matched, and the support plate 14 is installed on the upper and lower shaft ends of the sphere 4 respectively. The pin shaft 21 on the body 1 has a clearance fit, and the pin shaft 21 is installed on the other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com