Construction method of foundation pit inclined support pile and auxiliary tool thereof

A construction method and technology of auxiliary tools, applied in basic structure engineering, excavation, construction, etc., can solve problems such as delay in construction period, and achieve the effect of short construction period, shortened total construction period and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

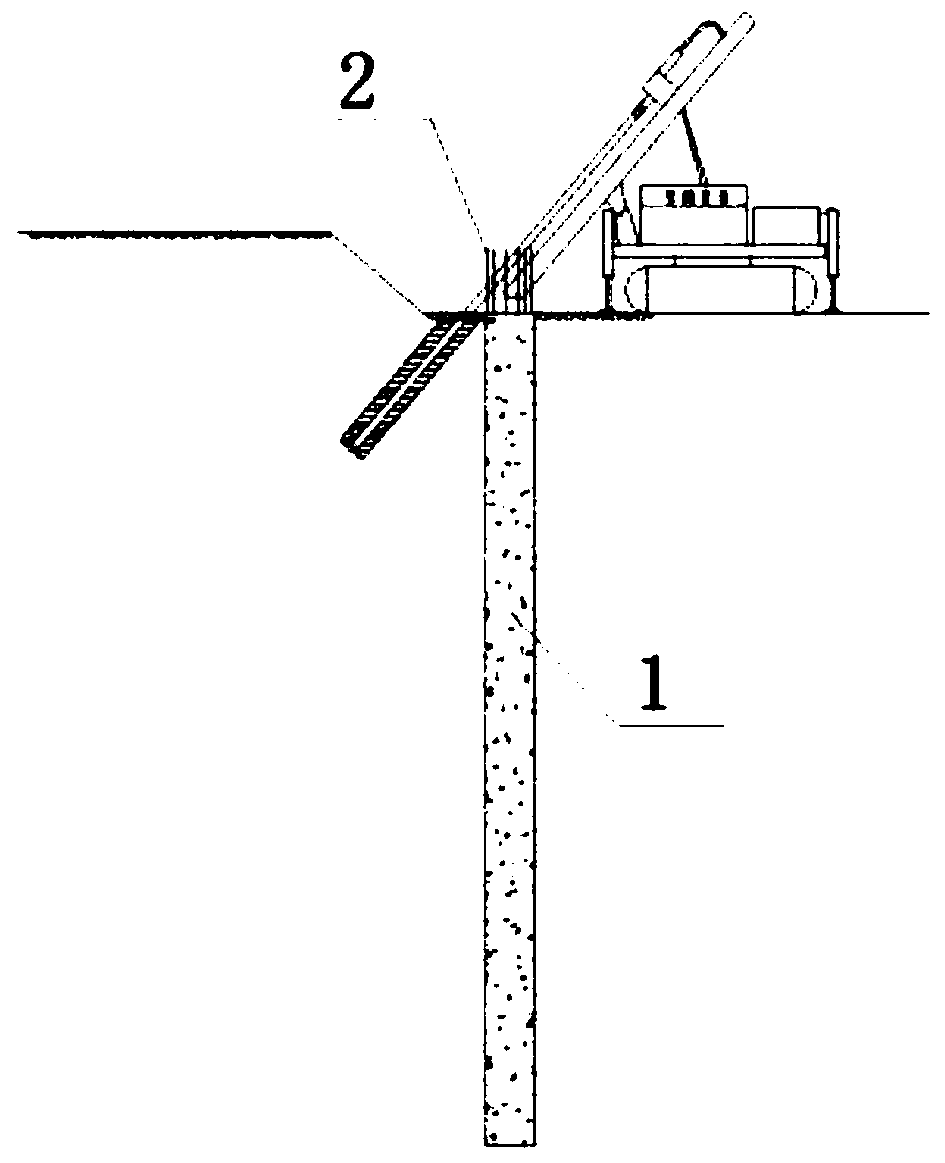

[0031] Figure 1~6 Shown is: a kind of construction method of diagonally braced pile in foundation pit, it is characterized in that comprising the following steps:

[0032] 1) Construction of support piles: construction of support pile 1 pile hole at the pile position, lowering the reinforcement cage and pouring concrete to form support piles, breaking the pile head to expose anchorage section reinforcement 2;

[0033] 2) Pile hole construction of diagonally braced piles: Construct pile holes along the position and direction of the pile holes of diagonally braced piles 7 to form empty boreholes 4 above the foundation pit bottom elevation 3 and bearing holes 5 below the foundation pit bottom elevation 3, bearing holes 5 Inject cement slurry;

[0034] 3) Construction of the diagonally braced pile: fix the auxiliary device 6 so that the supporting surface is on the same line as the empty bore hole 4 and the bearing hole 5, place the diagonally braced pile 7 on the supporting sur...

Embodiment 2

[0039] In order to further optimize the technical solution of Embodiment 1, the diagonally braced pile 7 in this embodiment is a steel pipe pile or a prefabricated pipe pile. Using steel pipe piles or prefabricated pipe piles is more convenient than using pouring concrete in the prior art, the construction period is shorter, and the construction efficiency is higher.

Embodiment 3

[0041] In order to further optimize the technical solution of embodiment 2, in the step 3) described in this embodiment, when the braced pile 7 is composed of multiple sections, the upper end of one section can be temporarily fixed to the reinforcement bar 2 of the anchor section, and the other section can be placed On the auxiliary device 6, after the two sections of the diagonal brace piles 7 are welded firmly, place them in the bearing hole 5. In the actual construction process, the diagonally braced pile 7 can be composed of multiple sections according to the length of the pile hole. The auxiliary device 6 is used to facilitate the welding of the two diagonally braced piles 7. After welding, the auxiliary device 6 is used to lower the pile, which can greatly improve the construction efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com