460MPa crack arresting steel plate with low cost and large heat input welding and manufacturing method thereof

A technology of large heat input welding and manufacturing method, which is applied in the field of low-cost, large heat input welding of 460MPa grade crack arrest steel plates and its manufacturing field, and can solve the problems that do not involve the crack arrest characteristics of steel plates, and the low temperature toughness is difficult to guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below with reference to the embodiments and accompanying drawings.

[0061] See Table 1 for the composition of the steel sheet of the present invention, Table 2 and Table 3 are the manufacturing process of the steel sheet of the present invention, and Table 4 is the performance of the steel sheet of the present invention.

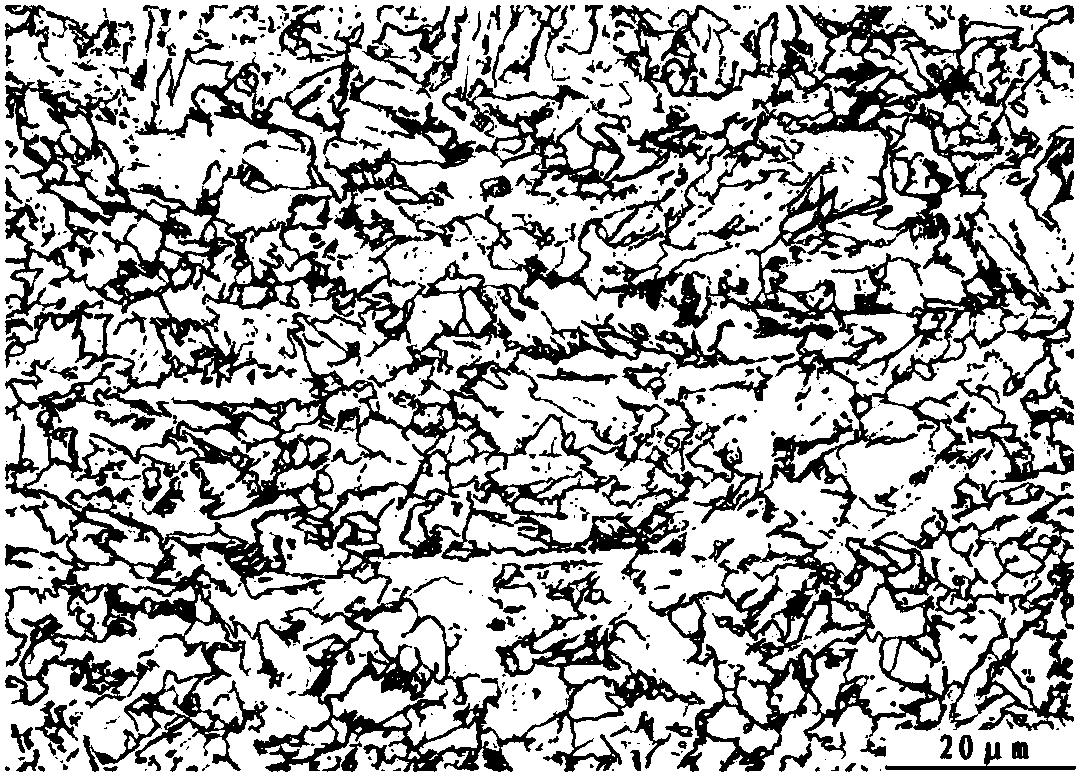

[0062] Depend on figure 1 It can be seen that the microstructure of the steel plate is uniform and fine ferrite + dispersed bainite, and the average grain size of the microstructure is below 10 μm; figure 2 It can be seen that the microstructure of the welded heat-affected zone of the steel plate is a fine and uniform intragranular ferrite or acicular ferrite structure.

[0063] By removing precious alloy elements Cu and Ni, the steel plate of the invention is designed with low-cost component combination, and combined with the TMCP manufacturing process, not only can the TMCP steel plate with excellen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com