Method for preparing jet fuel through hydrogenation of hydrogen counter flow grease

A technology for hydrogenation of jet fuel and oil, which is applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc. It can solve the problems of high energy consumption for recycling and reuse, inability to reduce production cost, shortening operation cycle, etc. The effect of reducing the energy consumption of hydrogen recovery, overcoming the shortening of the operation period of the device, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

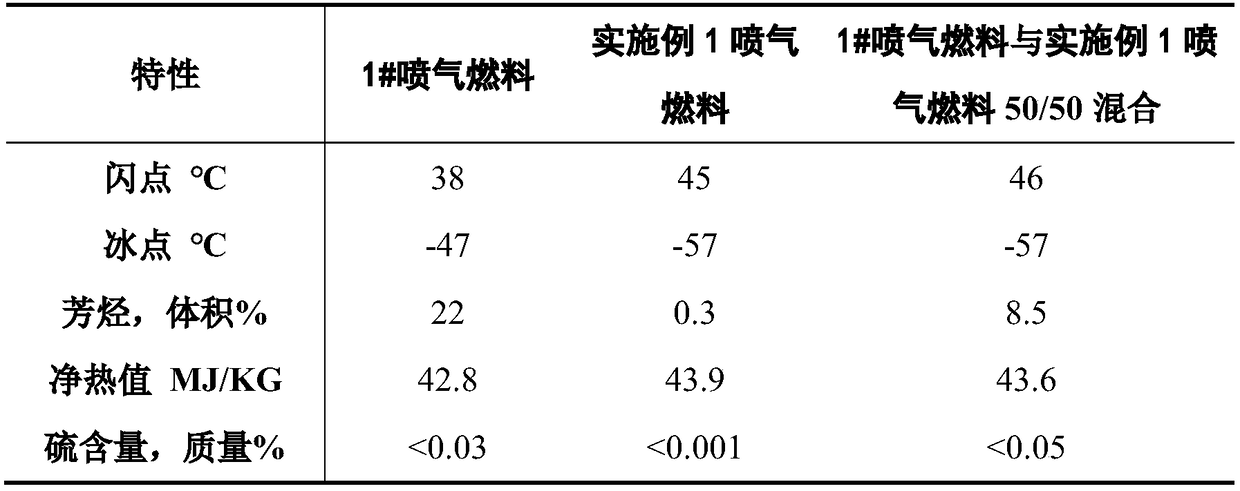

Embodiment 1

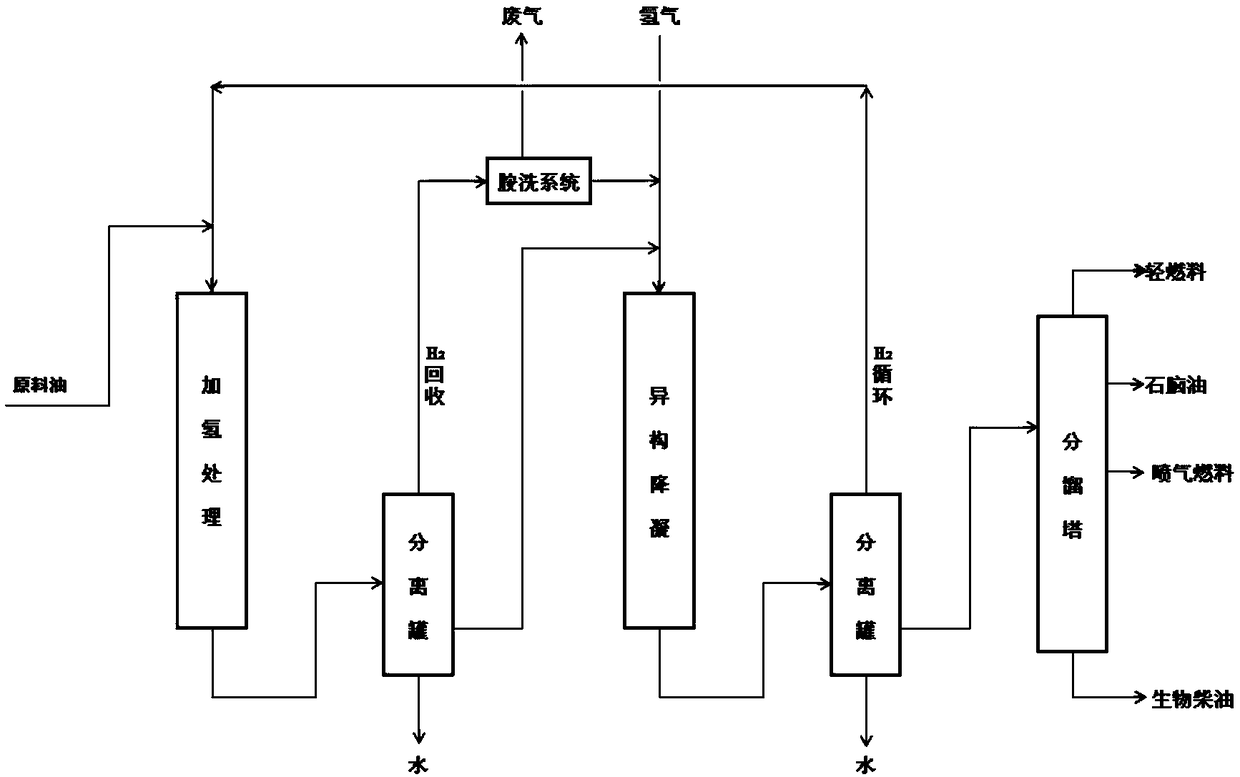

[0030] A method for preparing jet fuel by hydrogen countercurrent oil hydrogenation, comprising the following steps: (1) adding acidified oil into a hydrotreating reactor, and in the presence of hydrogen, contacting with a hydrotreating catalyst to perform a stage of hydrotreating to obtain refined oil (2) The refined oil is transferred to the isomerization depreciation reactor, and in the presence of hydrogen, is contacted with the isomerization catalyst to carry out two-stage hydroisomerization depreciation treatment, and then separated by distillation to obtain biodiesel;

[0031] During the whole reaction process, the method of adding hydrogen is as follows: new hydrogen is added in the second stage of hydroisomerization and decondensation treatment, and the hydrogen-rich gas obtained after the second stage of hydroisomerization and decondensation treatment is circulated to the first stage of hydrogenation treatment, and after the first stage of hydrogenation treatment The ...

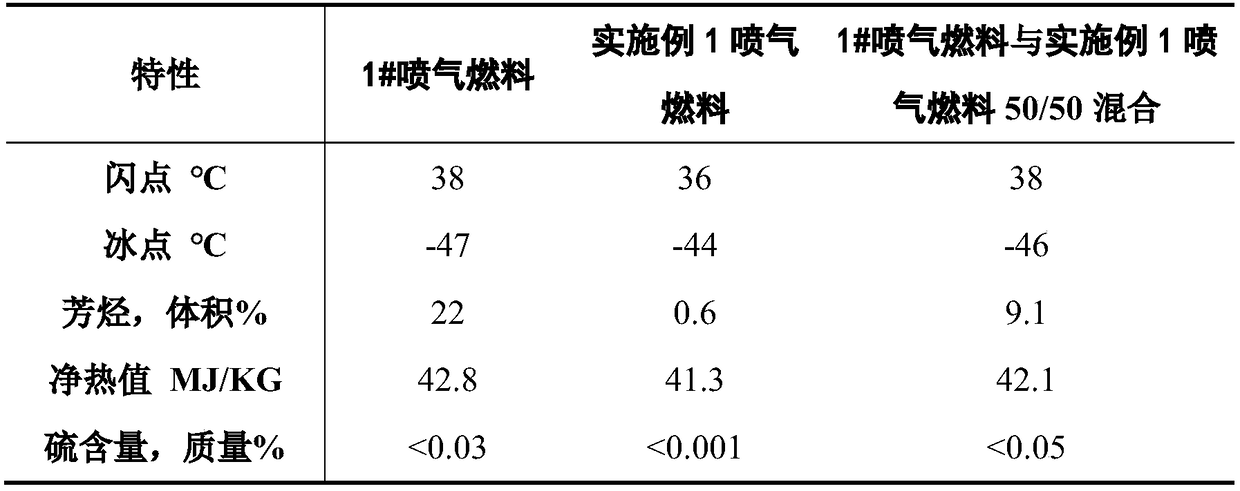

Embodiment 2

[0041] A method for preparing jet fuel by hydrogen countercurrent oil hydrogenation, comprising the following steps: (1) adding acidified oil into a hydrotreating reactor, and in the presence of hydrogen, contacting with a hydrotreating catalyst to perform a stage of hydrotreating to obtain refined oil (2) The refined oil is transferred to the isomerization depreciation reactor, and in the presence of hydrogen, is contacted with the isomerization catalyst to carry out two-stage hydroisomerization depreciation treatment, and then separated by distillation to obtain biodiesel;

[0042] During the whole reaction process, the method of adding hydrogen is as follows: new hydrogen is added in the second stage of hydroisomerization and decondensation treatment, and the hydrogen-rich gas obtained after the second stage of hydroisomerization and decondensation treatment is circulated to the first stage of hydrogenation treatment, and after the first stage of hydrogenation treatment The ...

Embodiment 3

[0052] A method for preparing jet fuel by hydrogen countercurrent oil hydrogenation, comprising the following steps: (1) adding acidified oil into a hydrotreating reactor, and in the presence of hydrogen, contacting with a hydrotreating catalyst to perform a stage of hydrotreating to obtain refined oil (2) The refined oil is transferred to the isomerization depreciation reactor, and in the presence of hydrogen, is contacted with the isomerization catalyst to carry out two-stage hydroisomerization depreciation treatment, and then separated by distillation to obtain biodiesel;

[0053] During the whole reaction process, the method of adding hydrogen is as follows: new hydrogen is added in the second stage of hydroisomerization and decondensation treatment, and the hydrogen-rich gas obtained after the second stage of hydroisomerization and decondensation treatment is circulated to the first stage of hydrogenation treatment, and after the first stage of hydrogenation treatment The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com