Spherical mesoporous composite material and supported catalyst and preparation method thereof

A composite material and mesoporous technology, applied in the field of mesoporous materials, can solve the problems of affecting catalytic activity, poor thermal stability and hydrothermal stability, and low ethylene polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a kind of preparation method of spherical mesoporous composite material, and this method comprises the following steps:

[0035] (1) providing mesoporous molecular sieve material or preparing a filter cake of mesoporous molecular sieve material as component a;

[0036] (2) providing silica gel or preparing a filter cake of silica gel as component b;

[0037](3) The component a and the component b are mixed and first ball milled, the obtained first ball mill slurry is mixed with water for slurrying, then the second ball mill is carried out to obtain the second ball mill slurry, and After the second ball mill slurry is spray-dried, it is screened by cyclone separation technology;

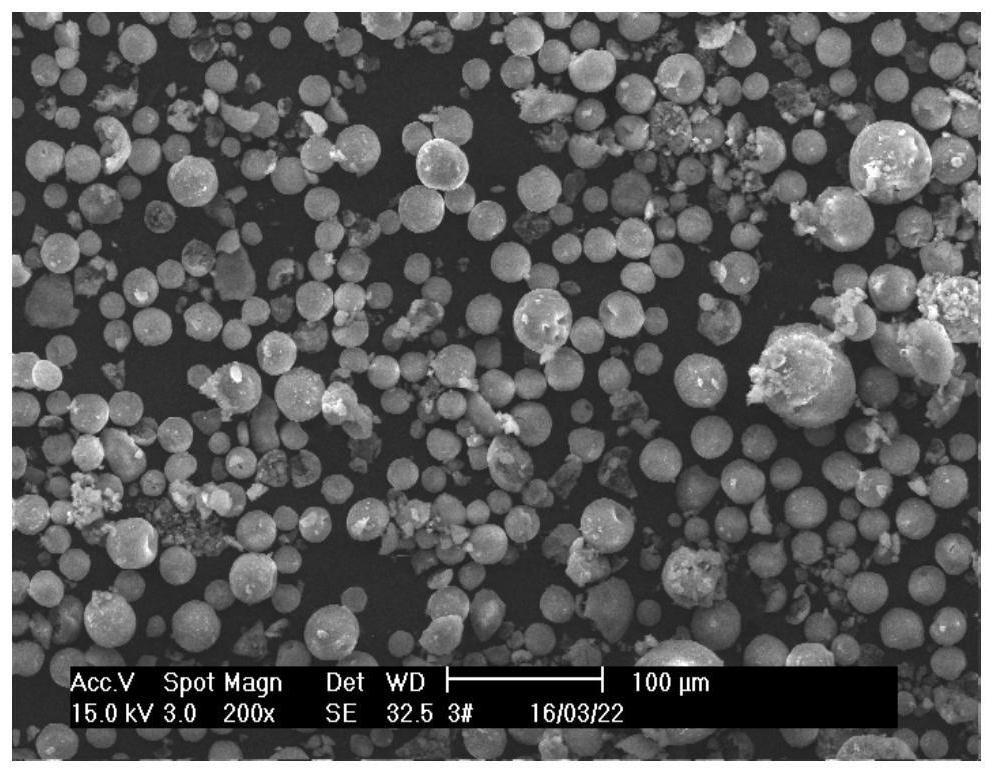

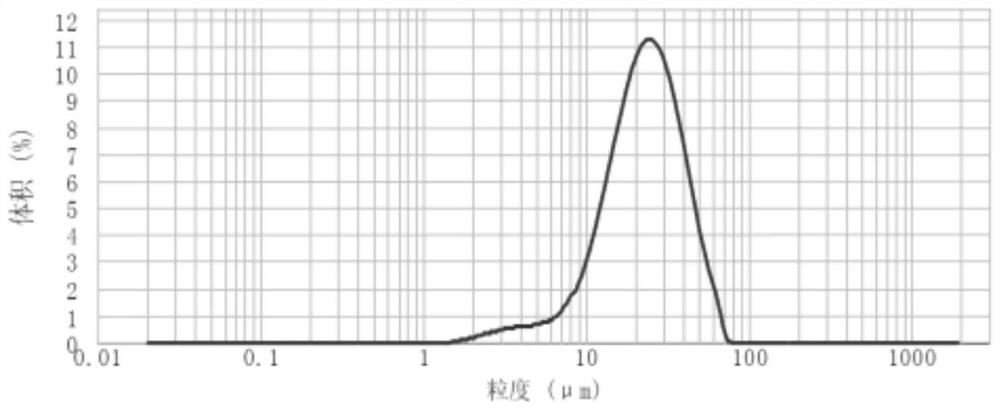

[0038] Wherein, the above steps make the spherical mesoporous composite material have an average particle diameter of 20-30 microns, a specific surface area of 100-300 square meters per gram, a pore volume of 0.5-1.8 milliliters per gram, and a bimodal dis...

Embodiment approach

[0049] According to a preferred embodiment of the present invention, the process of the first mixed contact includes: (1) cetyltrimethylammonium bromide (CTAB), polyethylene glycol octylphenyl ether (Trilar General X-100) and hydrochloric acid at 25-60°C until dissolved; (2) Stir the solution obtained in step (1) and silicate at 25-60°C for 10-72 hours, and let stand for 10-72 hours Hour.

[0050] In the present invention, the conditions for the crystallization are not particularly limited, and may be selected conventionally in the art. For example, the crystallization conditions include: the temperature may be 25-60° C., preferably 30-50° C.; the time may be 10-40 hours, preferably 15-35 hours. According to a preferred embodiment, the crystallization is carried out by hydrothermal crystallization.

[0051] In the present invention, in the above-mentioned process of preparing the filter cake of the mesoporous molecular sieve material, the process of obtaining the filter cake...

Embodiment 1

[0088] This example is used to illustrate the spherical mesoporous composite material and supported catalyst of the present invention and its preparation method

[0089] (1) Preparation of spherical mesoporous composites

[0090] 1.5 grams of CTAB (cetyltrimethylammonium bromide) and 1.5 ml of polyethylene glycol octylphenyl ether (Triton-X100) were added to 29.6 grams of 37% by weight of concentrated hydrochloric acid and 75 grams of In hydrochloric acid composed of water, mix and stir at 40°C until CTAB is completely dissolved; then add 4.35 grams of tetraethyl orthosilicate to the above solution, and stir for 15 hours at 40°C with a mechanical stirring rate of 340r / min , standing at 40° C. for 24 hours; the resulting solution was transferred to a polytetrafluoroethylene-lined reactor, crystallized at 50° C. for 24 hours, filtered and washed to obtain a mesoporous material filter cake A1.

[0091] The water glass with a concentration of 15% by weight and the sulfuric acid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com