Process for preparing granular oxamide

A manufacturing method and technology for oxamide, which are applied to nitrogen fertilizers, fertilizer mixtures, solid/semi-solid fertilizers, etc., can solve the problem of oxamide not using an inclined EIRICH mixer, etc., so as to reduce the workload of fertilization and the number of top dressings. , the effect of high fertilizer hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

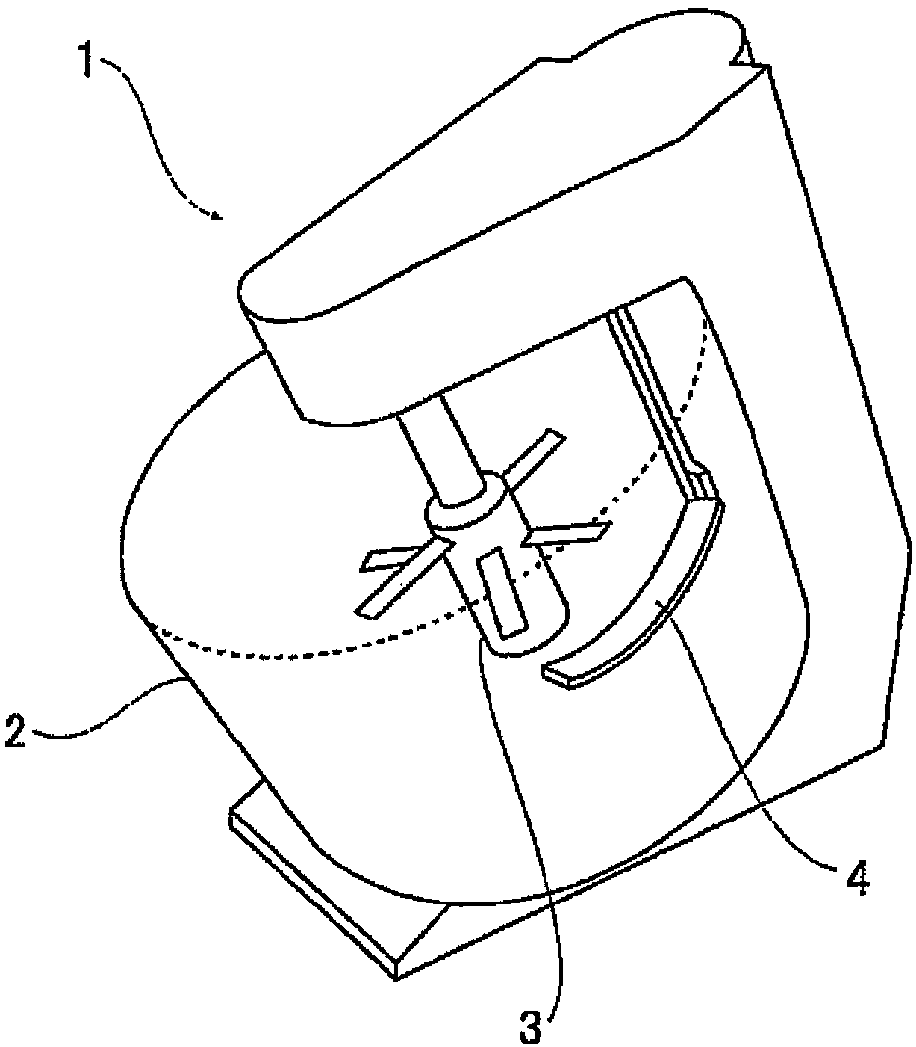

[0056] (Embodiment 1) Utilize inclined type Eirich mixer manufacture to add the granular oxamide of 1% modified PVA

[0057] A 5L beaker with 2.7 parts by weight of water was placed in a hot water bath at normal temperature, a stirring motor was set, and while stirring the water, 0.3 parts by weight of modified polyvinyl alcohol (manufactured by Kuraray Co., Ltd., 1300 degrees of polymerization) were slowly added. , Saponification degree 92~98). It heated while stirring, and after reaching 95 degreeC, it stirred for 2 hours, maintaining temperature. After confirming that the modified PVA was completely dissolved, the stirring force was lowered and cooled slowly to prepare a 10% solution.

[0058] After the oxamide powder of 20 parts by weight is dropped into the mixing disc container of inclined type Eirich mixer (manufactured by Japan Eirich Co., Ltd., strong mixer R02 type, the same below), add 2 parts by weight of prepared modified PVA 10% solution was mixed for 1 minute ...

Embodiment 2

[0059] (Embodiment 2) Utilize inclined type Eirich mixer manufacture to add the granular oxamide of 2%PVA

[0060] A 10 L beaker containing 5.4 parts by weight of water was placed in a hot water bath at normal temperature, a stirring motor was installed, and 0.6 parts by weight of PVA was slowly added while stirring the water. It heated while stirring, and after reaching 95 degreeC, it stirred for 2 hours, maintaining temperature. After confirming that the PVA was completely dissolved, the stirring power was reduced and cooled slowly to prepare a 10% solution.

[0061] After putting 20 parts by weight of oxamide powder into the mixing disk container of an inclined EIRICH mixer, add 4 parts by weight of the prepared PVA 10% solution, and mix for 1 minute at a rotor peripheral speed of 6 m / s (900 rpm). Further add 1.66 parts by weight of water, carry out dispersion and granulation for 21 minutes with a rotor peripheral speed of 19m / s (3000rpm), reduce the rotor peripheral speed...

Embodiment 3

[0062] (Embodiment 3) Utilize inclined type Eirich mixer manufacture to add the granular oxamide of 1%PVA

[0063] After the oxamide powder of 20 parts by weight is dropped into the mixing disc container of inclined type Eirich mixer, add the PVA10% solution prepared in 2 parts by weight of embodiment 2, mix 1 with rotor peripheral speed 6m / s (900rpm) minute. Further add 3.63 parts by weight of water, carry out dispersion and granulation for 22 minutes with a rotor peripheral speed of 19m / s (3000rpm), reduce the rotor peripheral speed to 6m / s (900rpm) and discharge after the same treatment for 2 minutes. The discharged granular product was dried with a drier at 105° C. for 4 hours, and then sieved to a particle size range of 2 to 4 mm to obtain granular oxamide containing 1% PVA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com