A special mortar for air-entrained concrete

A kind of air-entrained concrete and mortar technology, applied in the field of building materials, can solve the problems of inability to combine water-retaining wall adhesion and deformation resistance, decreased adhesion performance, and imperfect development of special mortar for air-entrained concrete. Effects of wall adhesion, surface tension reduction, and good deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

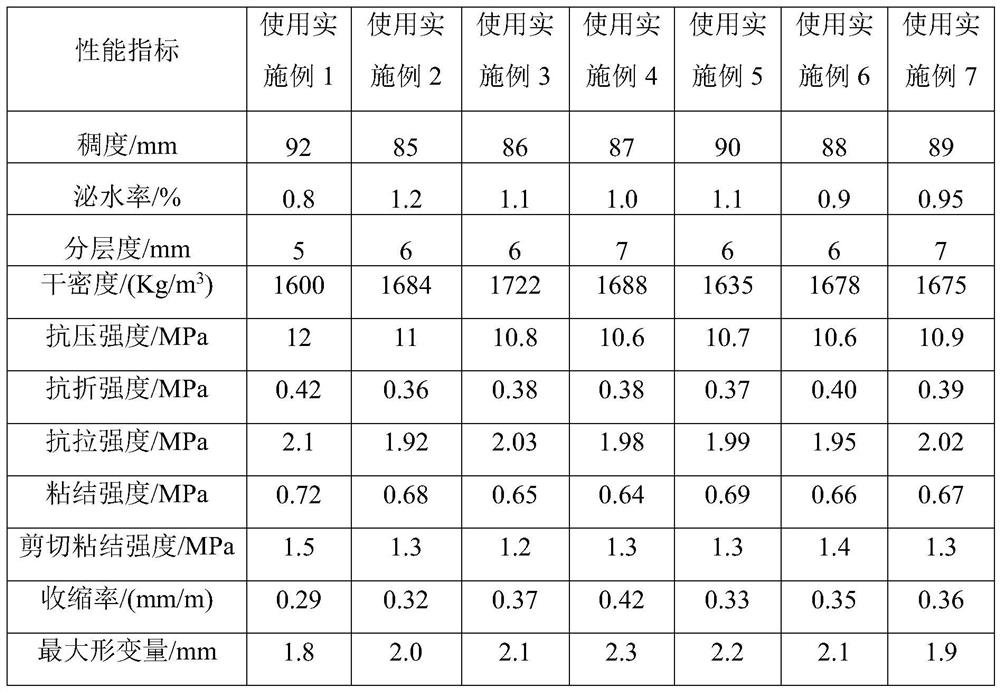

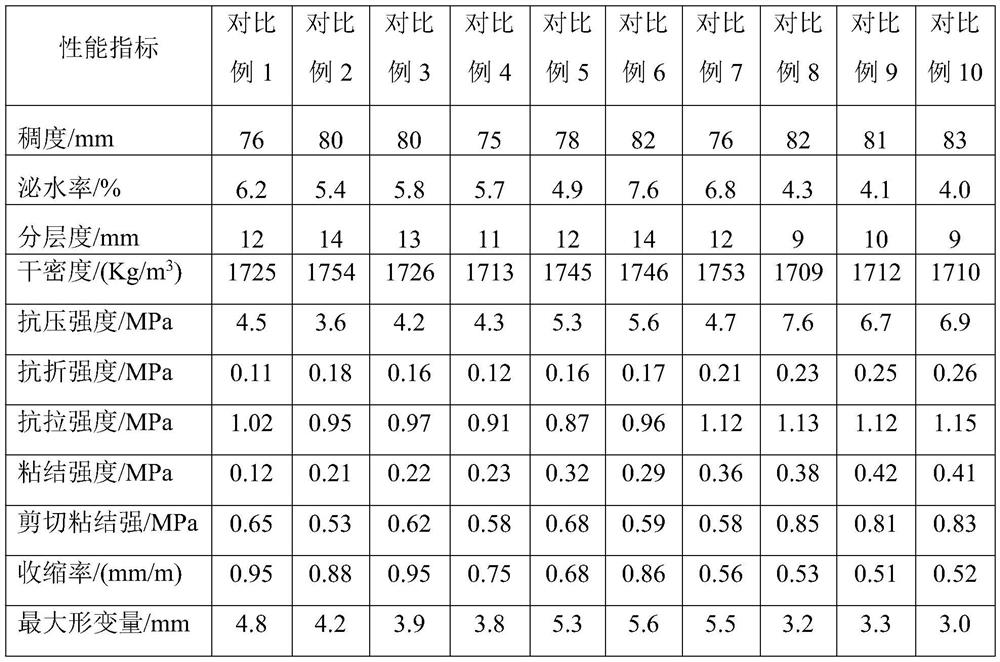

Examples

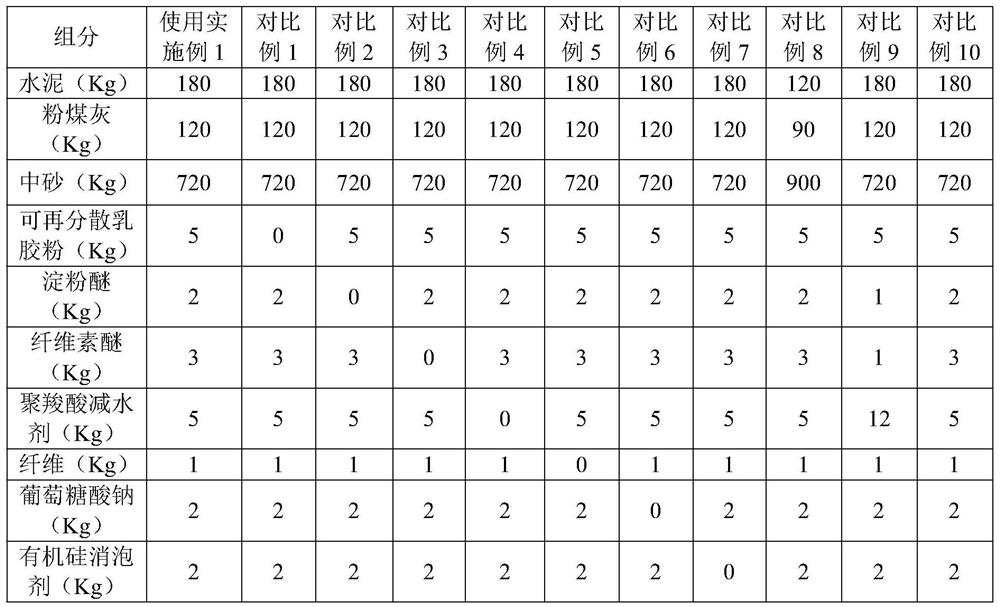

Embodiment 1

[0048] Weigh 180Kg of cement, 120Kg of fly ash, 720Kg of medium sand, 5Kg of redispersible latex powder, 2Kg of starch ether, 3Kg of cellulose ether, 5Kg of polycarboxylate superplasticizer, and 1Kg of fiber (polypropylene fiber and wood fiber, mass ratio 1:3), sodium gluconate 2Kg, silicone defoamer 2Kg. Put it into a mortar mixer, dry mix for 1 minute, add tap water accounting for 15%-25% of the dry powder weight, stir for 2 minutes, and then apply manually.

Embodiment 2

[0050] Weigh 160Kg of cement, 100Kg of fly ash, 600Kg of medium sand, 5Kg of redispersible latex powder, 1Kg of starch ether, 1Kg of cellulose ether, 1Kg of polycarboxylate superplasticizer, fiber (polypropylene fiber and wood fiber, the mass ratio is 1:2) 3Kg, sodium citrate 1Kg, polyether defoamer 1Kg. Put it into a mortar mixer, dry mix for 5 minutes, add tap water accounting for 15%-25% of the dry powder weight, stir for 10 minutes, and then apply manually.

Embodiment 3

[0052] Weigh 200Kg of cement, 140Kg of fly ash, 800Kg of medium sand, 10Kg of redispersible latex powder, 10Kg of starch ether, 10Kg of cellulose ether, 10Kg of polycarboxylate superplasticizer, fiber (polypropylene fiber and wood fiber, the mass ratio is 1:4) 6Kg, sodium gluconate 3Kg, silicone defoamer 2Kg. Put it into a mortar mixer, dry mix for 3 minutes, add tap water accounting for 15%-25% of the dry powder weight, stir for 7 minutes, and then apply manually.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com