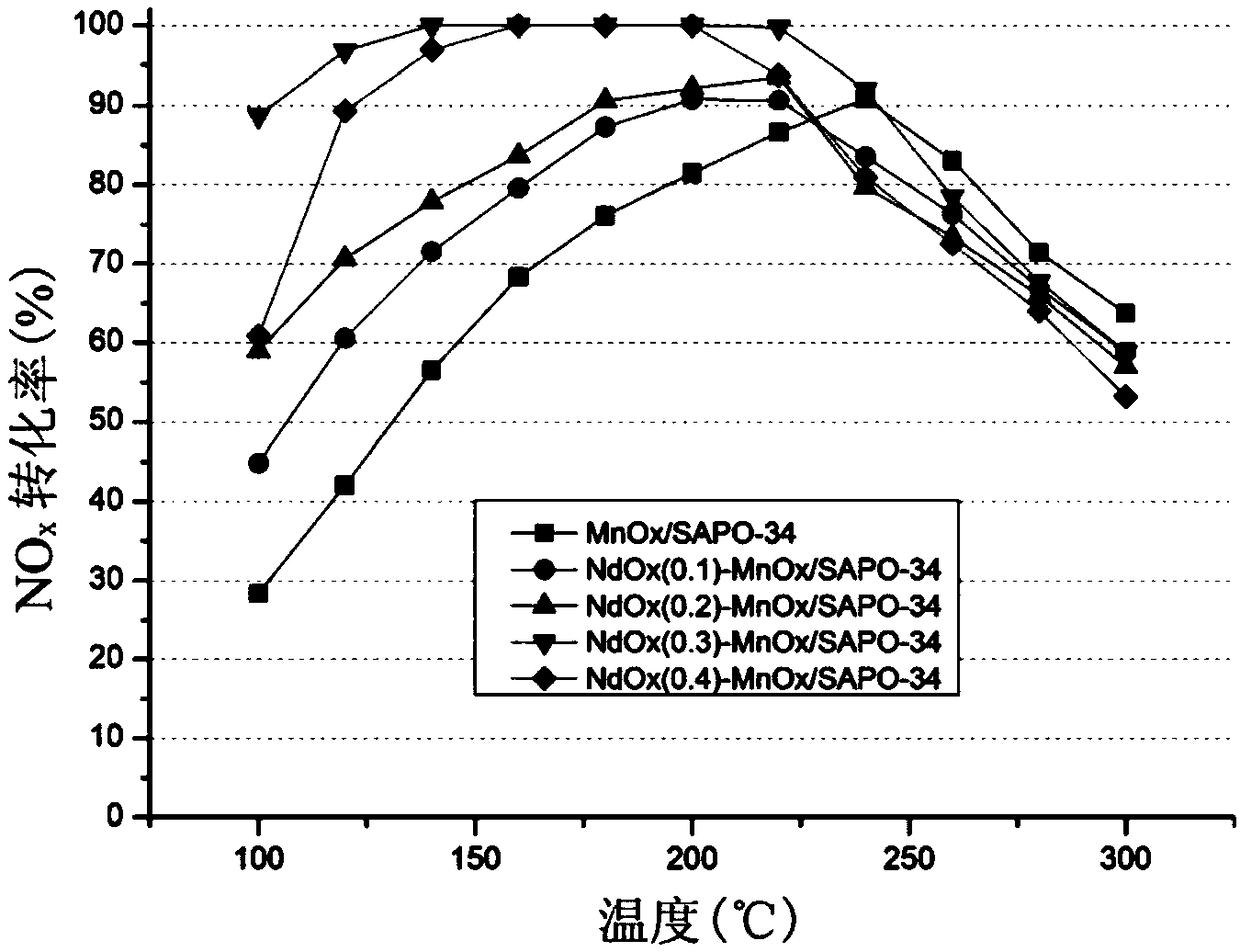

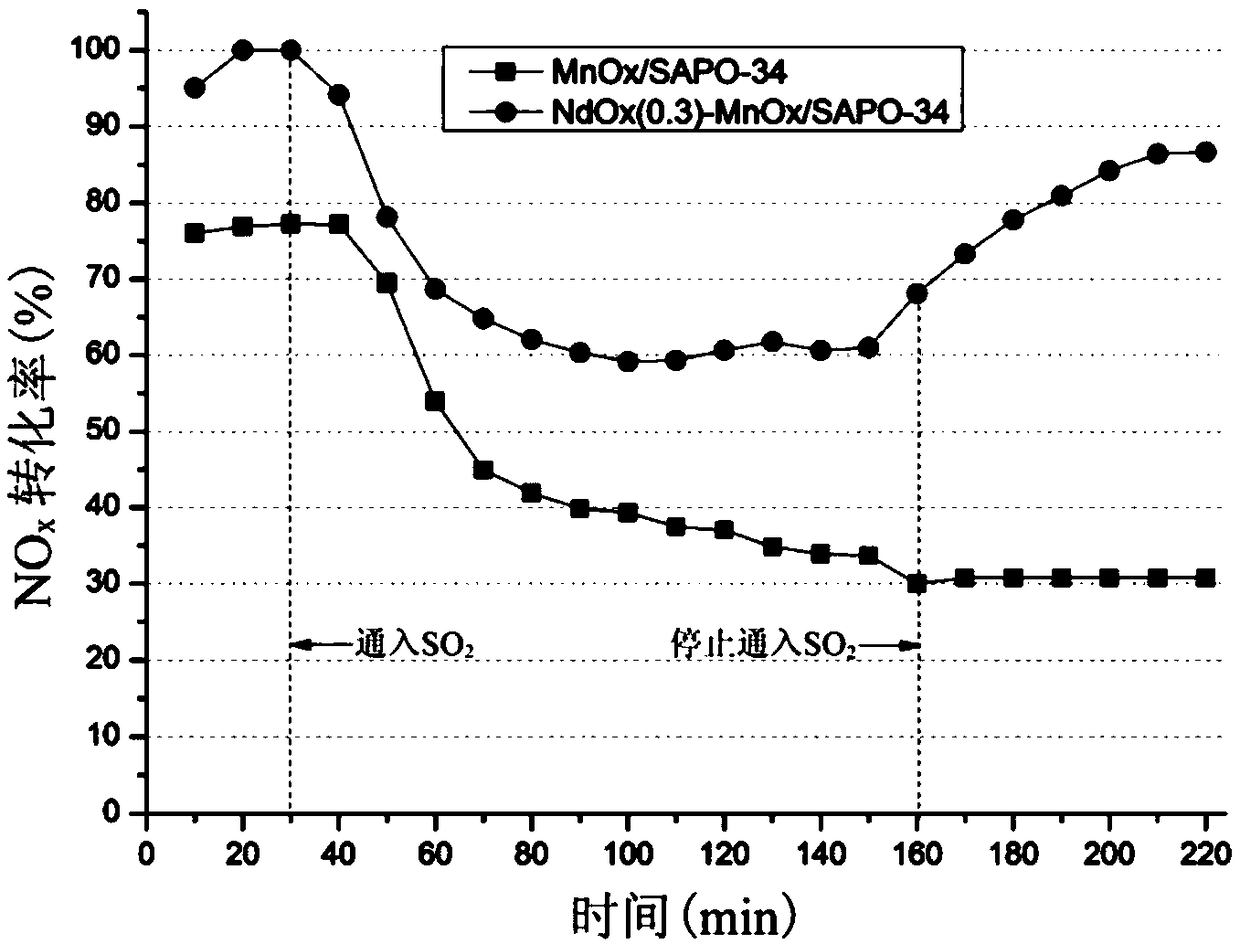

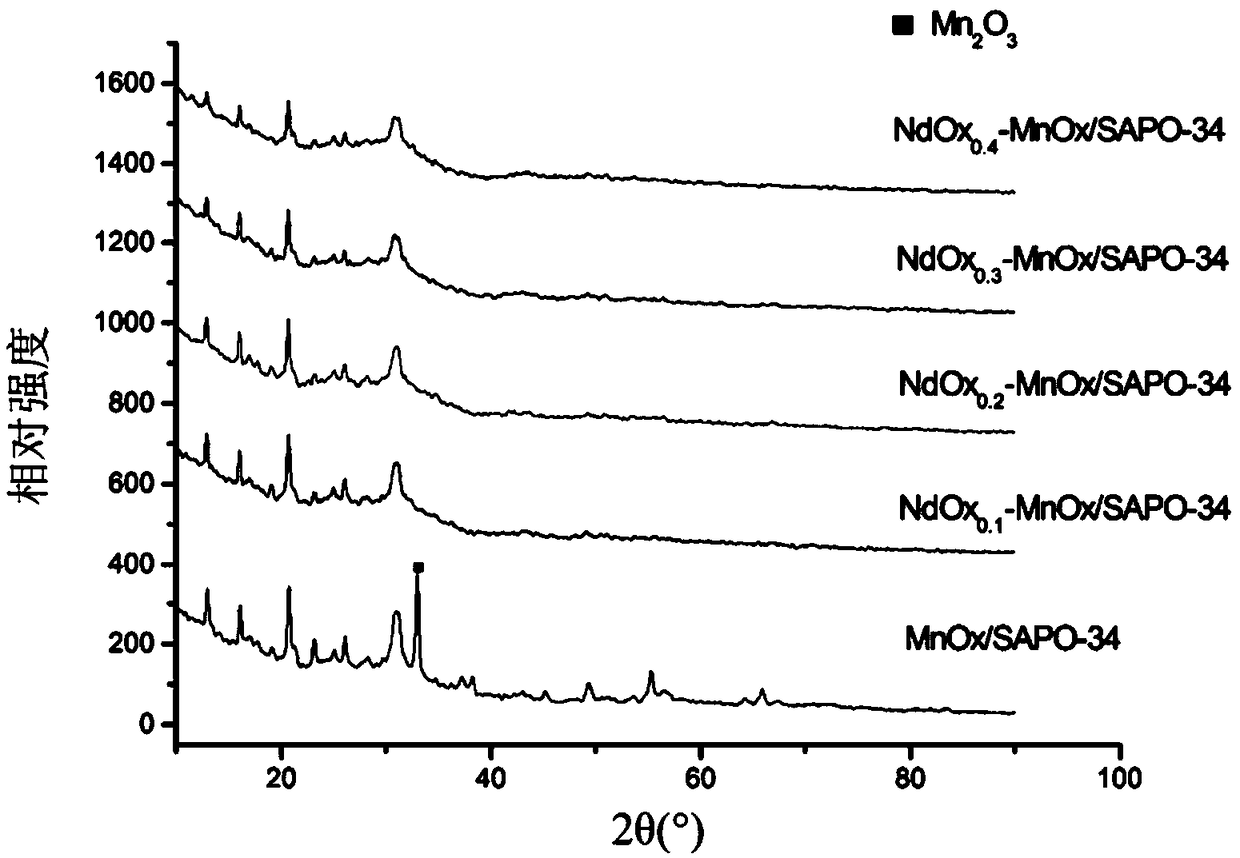

Medium and low temperature denitrification catalyst with Mn as active metal and Nd as assistant and preparation method of medium and low temperature denitrification catalyst

A low-temperature denitrification and active metal technology, applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of catalyst performance degradation, engineering design difficulties, short catalyst life, etc., to achieve good low-temperature activity and improve NOx Effect of conversion rate and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of above-mentioned catalyst comprises following major steps:

[0023] (1) Measure 100mL of absolute ethanol and pour it into a clean beaker for later use;

[0024] (2) Take the manganese nitrate solution and SAPO-34 powder with a mass fraction of 50wt.% with a precision electronic balance, pour it into the beaker of step (1), and seal it with plastic wrap, then put the beaker into an ultrasonic disperser for ultrasonic dispersion make the solution uniform;

[0025] (3) In the solution obtained in step (2), add different amounts of neodymium nitrate crystals (Nd(NO 3 ) 3 ·6H 2 (2), obtain 5 parts of samples, put into the magnetic stirring bar in the beaker of each sample, put into the constant temperature water bath and stir in the water bath, until most of the liquid evaporates in the beaker, obtain the colloidal sample;

[0026] (4) Put the five samples of step (3) in a drying oven for constant temperature drying and dehydration, and take out...

Embodiment 1

[0028] (1) Measure 100mL of absolute ethanol and pour it into a clean beaker for later use.

[0029] (2) Take 7.8176g mass fraction of 50wt.% manganese nitrate solution and 6.000 gSAPO-34 powder with precision electronic balance, pour in the beaker of step (1), and seal with plastic wrap, then put the beaker into the ultrasonic disperser Ultrasonic dispersion for 1 h to make the solution uniform.

[0030] (3) Put a magnetic stirrer into the beaker of the solution obtained in step (2), put it into a constant temperature water bath at 60°C and stir in a water bath until most of the liquid in the beaker evaporates to obtain a colloidal sample.

[0031] (4) Place the sample in step (3) in a drying oven at a constant temperature of 105°C for 6 hours to dry and dehydrate, and take out the solid sample with a medicine spoon, put it into a mortar for grinding, and sieve it with a 100-mesh sieve to collect the sample. Finally, the sample powder was calcined in a muffle furnace at 500 ...

Embodiment 2

[0033] (1) Measure 100mL of absolute ethanol and pour it into a clean beaker for later use.

[0034] (2) Take 7.8176g mass fraction of 50wt.% manganese nitrate solution and 6.000 gSAPO-34 powder with precision electronic balance, pour in the beaker of step (1), and seal with plastic wrap, then put the beaker into the ultrasonic disperser Ultrasonic dispersion for 1 h to make the solution uniform.

[0035] (3) in step (2) gained solution, be 0.1 to add neodymium nitrate crystal according to Nd / Mn molar ratio, promptly add the neodymium nitrate hexahydrate of 0.9576g, obtain sample, put magnetic stirring bar in the beaker of sample, put Stir in a constant temperature water bath at 60°C until most of the liquid in the beaker evaporates to obtain a colloidal sample.

[0036] (4) Place the sample in step (3) in a drying oven at a constant temperature of 105°C for 6 hours to dry and dehydrate, and take out the solid sample with a medicine spoon, put it into a mortar for grinding, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com