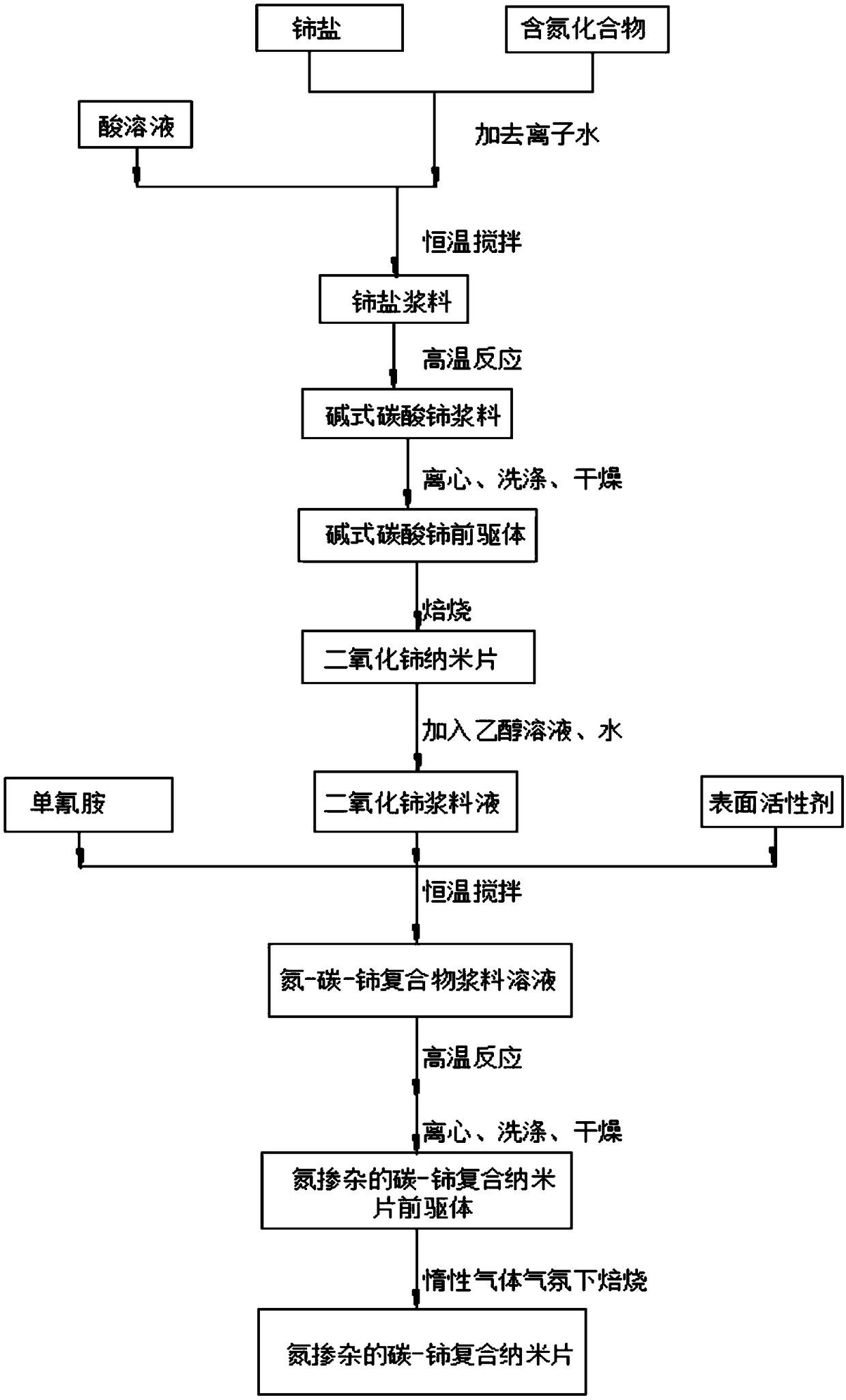

Preparation method of nitrogen-doped carbon-cerium composite nanosheets

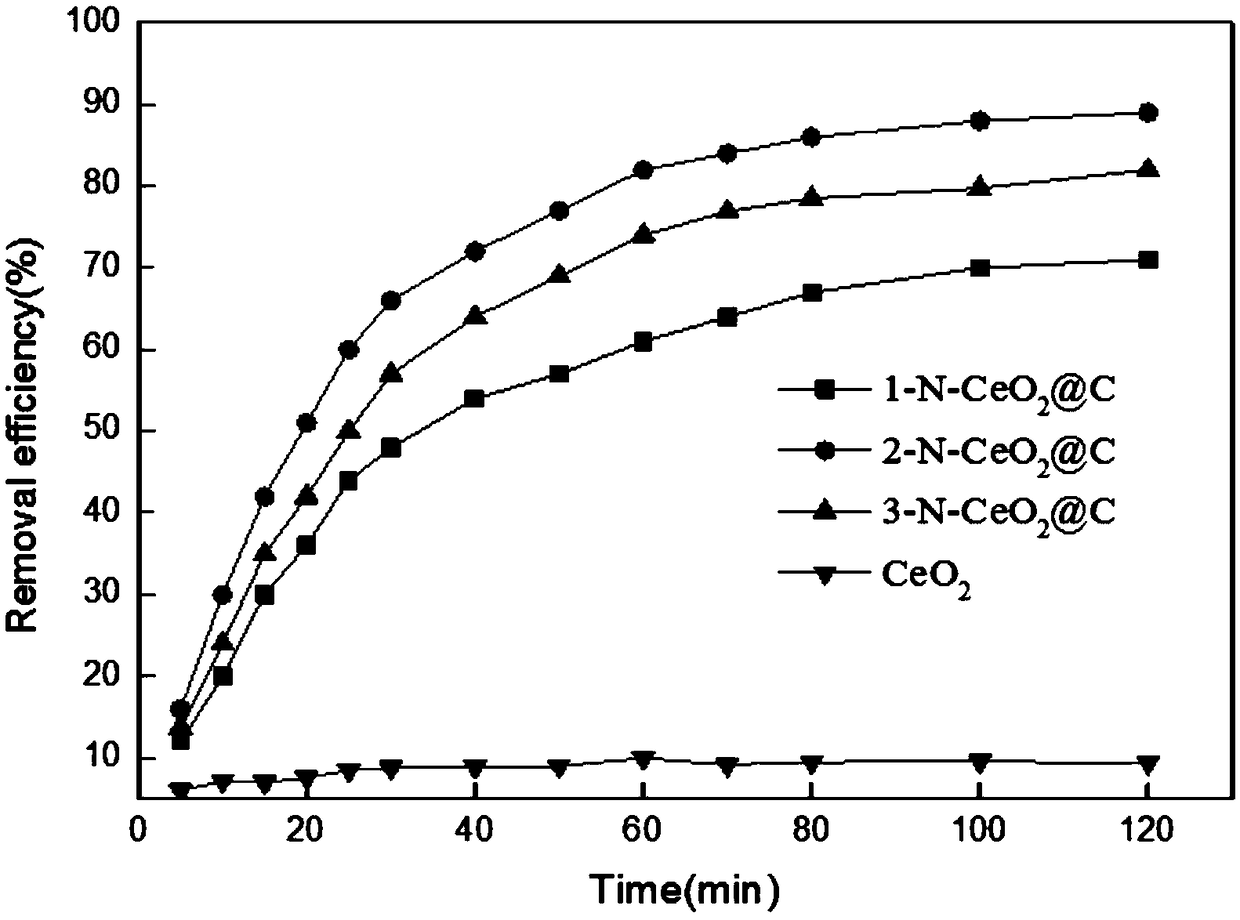

A nanosheet and nitrogen-doped technology, which is applied in separation methods, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of no obvious effect of catalytic oxidation, improve visible light absorption capacity, and be easy to operate , Improve the effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing nitrogen-doped carbon-magnesium composite nanosheets of the present invention, specifically:

[0033] Step 1. Preparation of cerium salt slurry: cerium nitrate hexahydrate (Ce(NO) 3 ·6H 2 O): 1.3026g and hexamethylenetetramine (C 6 h 12 N 4 ): 2.9469g was added to 70mL deionized water, stirred evenly at a constant temperature of 25°C, then 3mL of glacial acetic acid was added to adjust the pH of the system to 8.5, and stirred at a constant temperature of 25°C and a stirring speed of 450r / min for 4h to obtain cerium salt slurry;

[0034] Step 2. Prepare basic cerium carbonate precursor: put the cerium salt slurry solution into a hydrothermal reaction kettle and react at 160°C for 12 hours to obtain basic cerium carbonate slurry. After natural cooling, remove the supernatant, and The remaining slurry is centrifuged, and the obtained filter cake is washed with deionized water and ethanol for 3 times respectively; then dr...

Embodiment 2

[0040] This embodiment provides a method for preparing nitrogen-doped carbon-magnesium composite nanosheets of the present invention, specifically:

[0041] Step 1. Preparation of cerium salt slurry: cerium nitrate hexahydrate (Ce(NO) 3 ·6H 2 O): 5.8514g and hexamethylenetetramine (C 6 h 12 N 4): Add 9.5842g to 50mL deionized water, stir evenly at a constant temperature of 50°C, then add 1mL of sulfuric acid to adjust the pH of the system to 4.5, and stir at a constant temperature of 50°C and a stirring speed of 400r / min for 2h to obtain cerium salt slurry;

[0042] Step 2. Prepare basic cerium carbonate precursor: put the cerium salt slurry solution into a hydrothermal reactor and react at 180°C for 10 hours to obtain basic cerium carbonate slurry. After natural cooling, remove the supernatant, and The remaining slurry is centrifuged, and the obtained filter cake is washed with deionized water and ethanol for 3 times respectively; then dried to obtain the basic cerium ca...

Embodiment 3

[0048] This embodiment provides a method for preparing nitrogen-doped carbon-magnesium composite nanosheets of the present invention, specifically:

[0049] Step 1. Preparation of cerium salt slurry: Add 3.5185g of cerium carbonate and ammonia water (1moL / L): 5.0568g into 80mL of deionized water, stir evenly at a constant temperature of 35°C, then add 5mL of hydrochloric acid, adjust the pH value to 6, and Stir at a constant temperature for 5 hours at a temperature of 35°C and a stirring speed of 800r / min to prepare a cerium salt slurry;

[0050] Step 2. Prepare basic cerium carbonate precursor: put the cerium salt slurry solution into a hydrothermal reactor and react at 140° C. for 15 hours to obtain basic cerium carbonate slurry. After natural cooling, remove the supernatant, and The remaining slurry is centrifuged, and the obtained filter cake is washed with deionized water and ethanol for 3 times respectively; then dried to obtain the basic cerium carbonate precursor;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com